CYLINDER HEAD ASSEMBLY 12

To correct a valve seat

with a valve seat cutter12A-13

Special tools:

Cutter for 46° inlet valve seats, MS.281*

Cutter for 31° inlet valve seats, MS.642

Cutter for exhaust valve seats, MS.275*

Pilot for use with valve seat cutters, MS.150-9.5*

Handle set for use with valve seat cutters, MS.67B*

*Included in set of adjustable cutters for valve seats,

MS.73

1 Before any work is done on the valve seats, new

valve guides must be fitted, operation 12A-11.

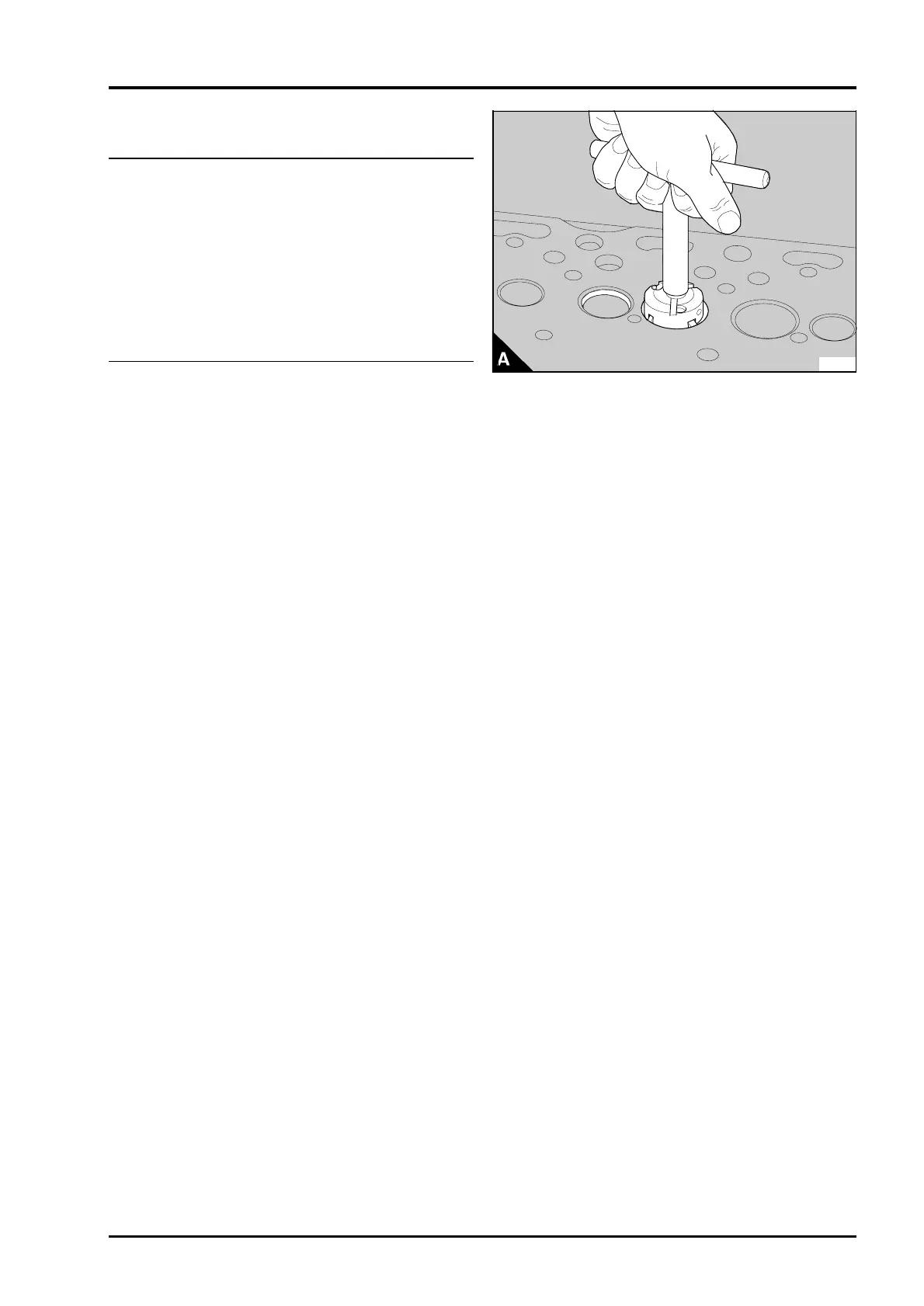

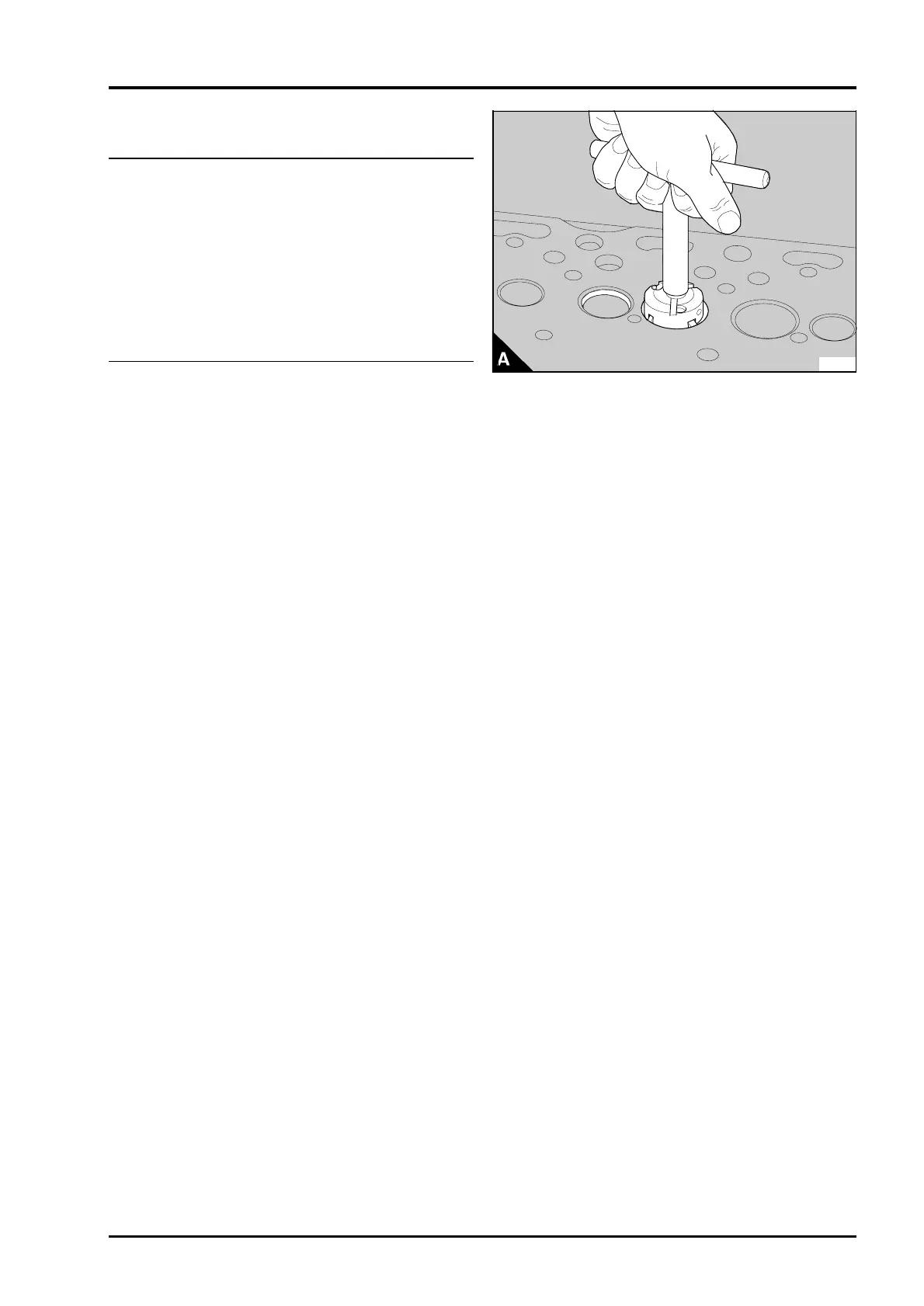

2 Fit the pilot in the valve guide and tighten the

pilot.

3 Select the relevant cutter. Set the blades of the

cutters to the diameter of the valve seat to be cut.

Fit the cutter on the pilot and fit the handle (A).

Ensure that the cutter is not allowed to fall on to the

seat as this can damage the blades.

4 Carefully turn the cutter in a clockwise direction.

Remove only the minimum material to ensure a

good seat. Keep the seat as narrow as possible.

5 When the seat is cut, remove the cutter and the

pilot. Remove any debris from the area of the valve

seat and the port.

6 Fit the valve and lightly lap the valve and the

seat.

7 Check that the valve depth is within limits, see

data and dimensions.

Note: If a valve seat has become too damaged or

too worn to correct, a valve seat insert can be

fitted, operation 12A-14. Turbocharged engines and

some naturally aspirated engines have valve seat

inserts fitted as standard and these inserts can be

renewed.

PA066

Perkins Phaser/1000 Series, April 1995 12A.21

Loading...

Loading...