LUBRICATION SYSTEM 19

Flexible oil pipes

The latest oil cooler pipes fitted to 6 cylinder

Phaser and 1000 Series engines do not have metal

braid and are separate pipes. The part number of

the pipes is stamped on a clip which is fastened to

one end of each pipe. The pipes are not

interchangeable and it is important that the correct

pipes are fitted to the engine.

To remove, to fit and to inspect19A-11

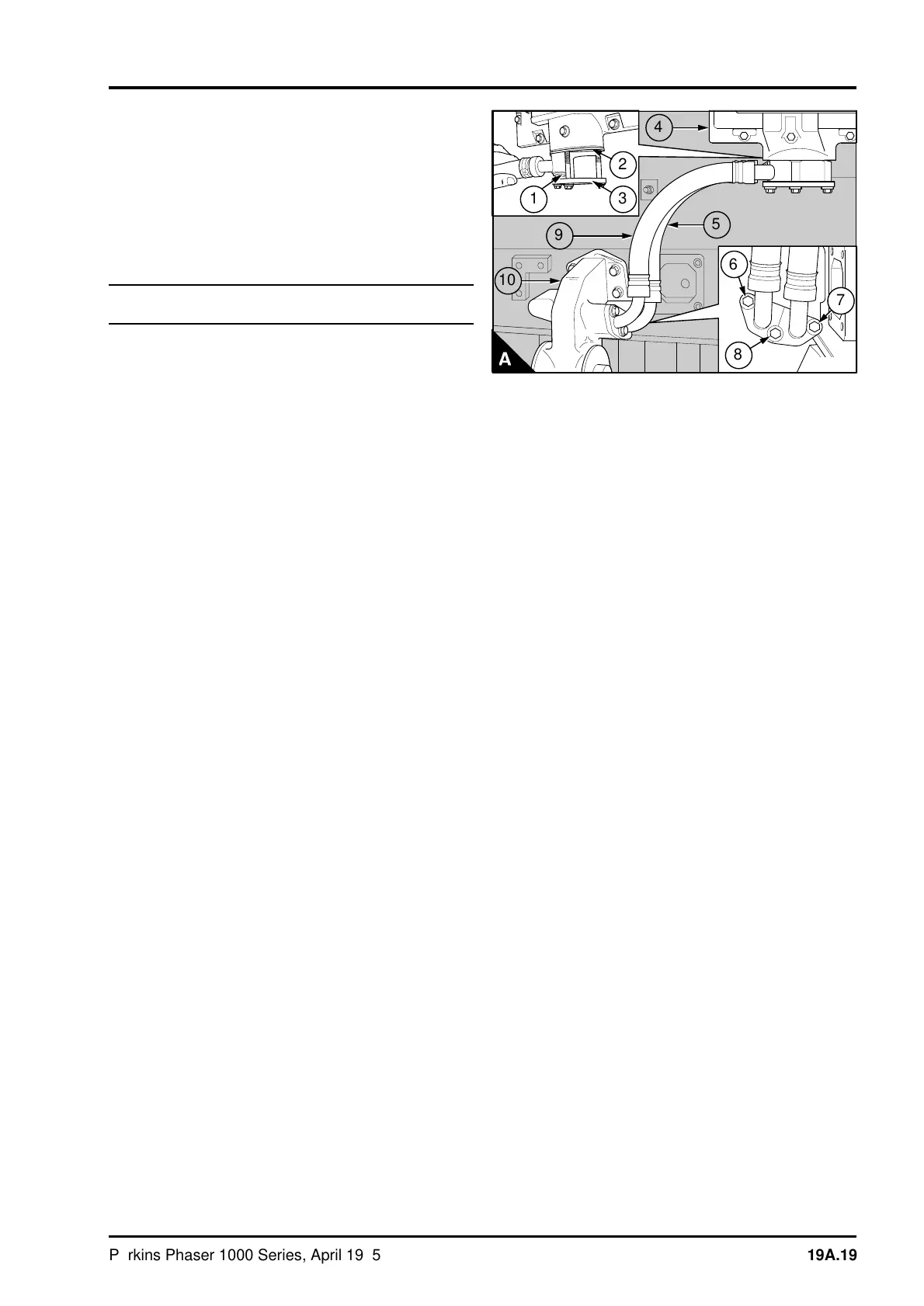

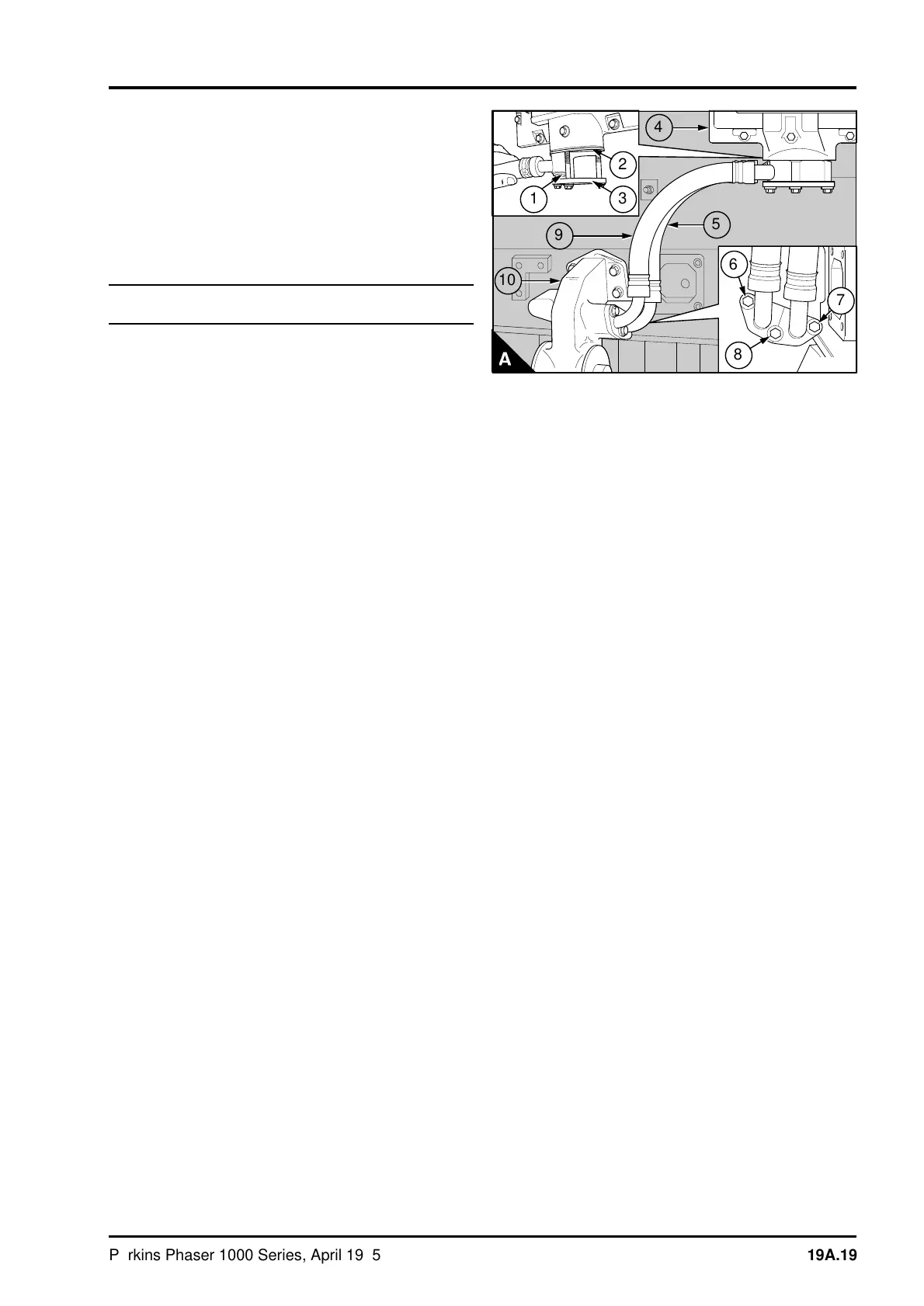

There are two arrangements (A) or (B) for the pipes

which are used in accordance with the application:

To remove

Warning! The engine oil may be hot, allow the

engine temperature to cool down before the oil

pipes are released.

1 Allow the engine temperature to cool down and

put a suitable drip tray under the filter head.

2 Remove the three setscrews which retain the oil

pipes to the filter head. Release the oil pipes and

allow the oil to drain into the drip tray. Discard the

joint.

3 Remove the three setscrews which retain the oil

pipes to the oil cooler. Discard the joint.

To fit the pipes - arrangement 1:

1 Put the three setscrews into position in the

flange (A3) of the inner pipe (A5), part number

2483A005. Put a new joint (A2) in position on the

setscrews.

2 Engage the setscrews by three or four threads in

the flange of the oil cooler (A4). Engage the spigot

(A1) of the outer pipe (A9), part number 2483A006,

in the hole in the flange (A3) of the first pipe,

ensure that it fits squarely in the flange.

3 Support the pipes by hand and tighten the centre

setscrew finger tight. Tighten the other setscrews

until they are finger tight. Ensure that the pipes are

as close together as possible, then tighten the

setscrews gradually and evenly to 22 Nm (16 lbf ft)

2,2 kgf m.

4 Put a setscrew (A7) in position in the flange of

the inner pipe (A5) for the oil filter head (A10). Put

a new joint in position on the setscrew. Hold the

flange and the joint in position and fit the centre

setscrew (A8). Tighten the setscrews finger tight.

Put the flange of the outer pipe (A9) in position and

fit the third setscrew (A6), tighten it finger tight.

Beginning with the centre setscrew, tighten the

three setscrews to 22 Nm (16 lbf ft) 2,2 kgf m.

PA304

a

a

1

a

a

3

a

a

2

5

6

8

a

a

4

a

a

9

a

a

a

a

10

7

Perkins Phaser/1000 Series, April 1995 19A.19

Loading...

Loading...