CYLINDER HEAD ASSEMBLY 12

To inspect and to correct12A-09

Special tool:

Gauge, valve depth, PD.41D

Dial gauge for use with PD.41D, PD.208

1 Check the depth of the valves below the face of

the cylinder head before the valve springs are

removed.

2 Ensure that the heads of the valves and the

bottom face of the cylinder head are clean.

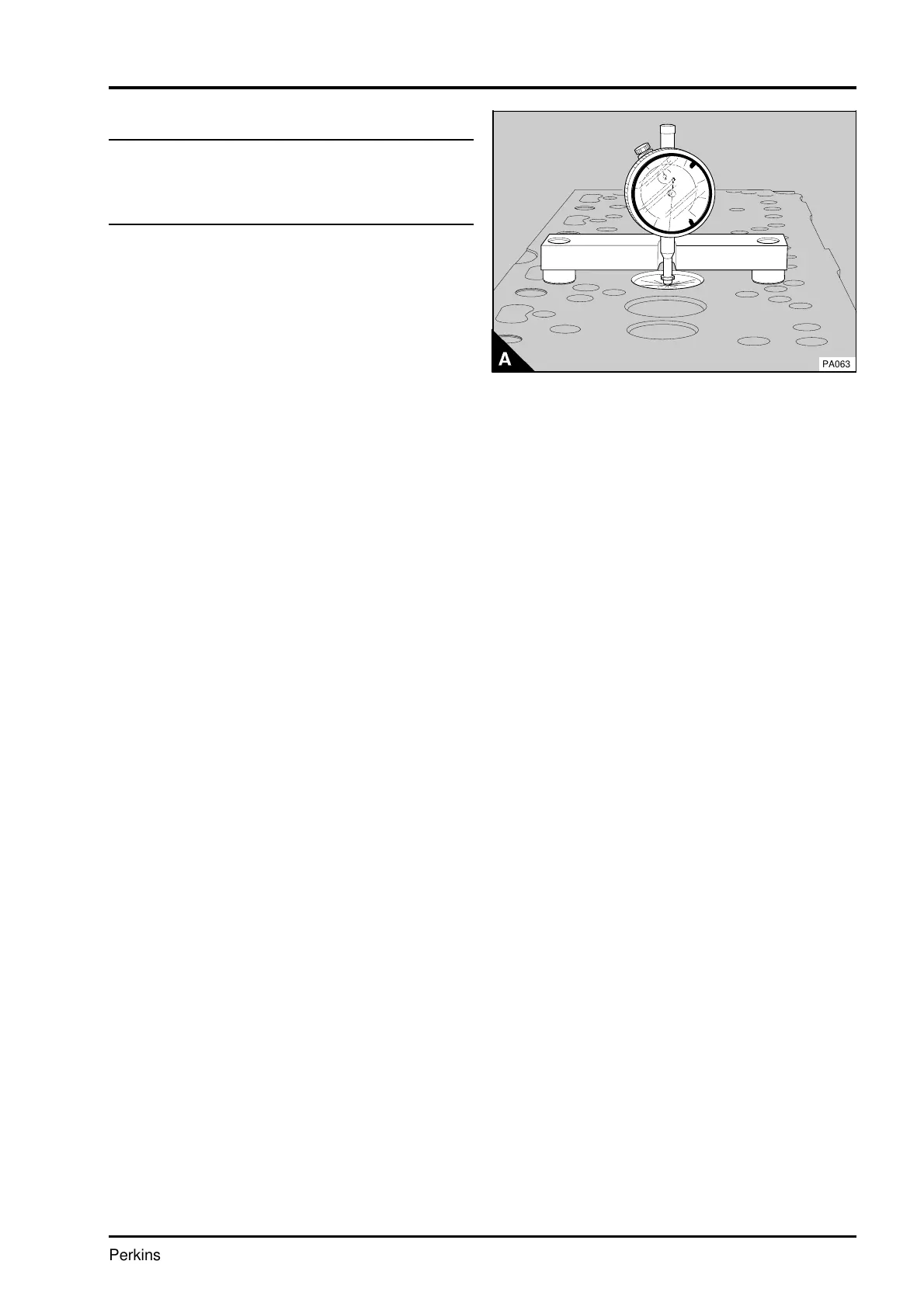

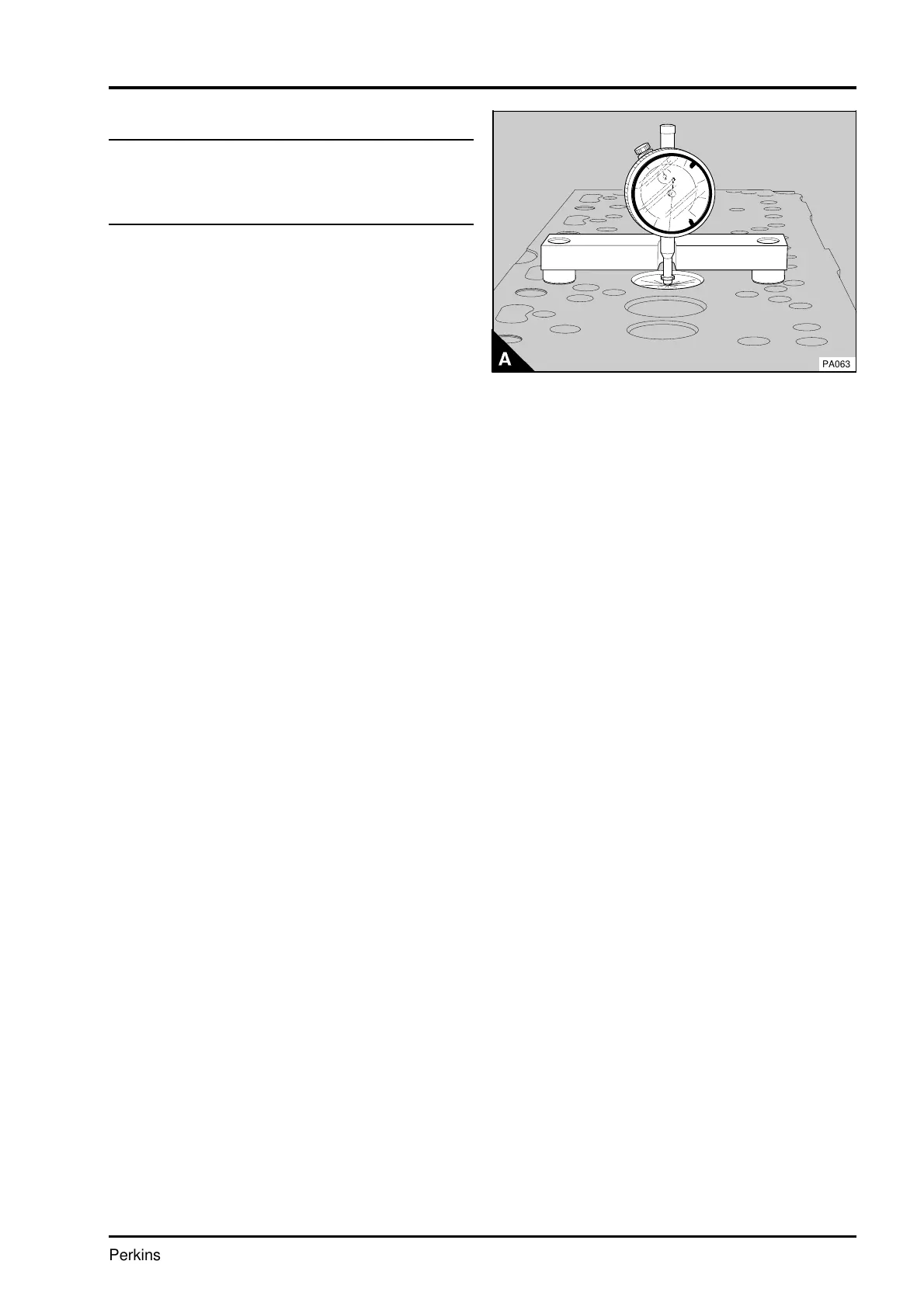

3 Put the valve depth gauge on the face of the

cylinder head and zero the dial gauge.

4 Carefully put the valve depth gauge in position

over the head of each valve (A) and make a note of

the measurement. The maximum depth, in service,

is given in the data and dimensions.

5 If a valve is below the depth limit, check the

valve depth with a new valve in position. If the valve

depth is still below the limit and a valve seat insert

is fitted, the insert must be renewed.

6 Where a valve seat insert is not fitted, the bottom

face of the cylinder head can be machined to

reduce the valve depth, or an insert can be fitted,

operation 12A-14.

Caution: If the bottom face of the cylinder head is

to be machined, ensure that the thickness, of the

cylinder head will not be less than 102,48 mm

(4.035 in) after the cylinder head has been

machined.

7 Check the valves for cracks. Check the stems of

the valves for wear and for correct fit in their valve

guides.

8 Check that the seat faces of the valves are not

badly burnt or damaged. Seat faces of valves which

are damaged can be ground on a special machine.

Valves which have only a little damage can be

lapped to their valve seats. When new valves are

fitted, the valve depths must be checked, see

paragraph 1.

9 Check that the load on the valve springs is

correct at their fitted length, see the data and

dimensions. Fit new valve springs at every

complete engine overhaul.

PA063

Perkins Phaser/1000 Series, April 1995 12A.17

Loading...

Loading...