12 CYLINDER HEAD ASSEMBLY

Valve guides

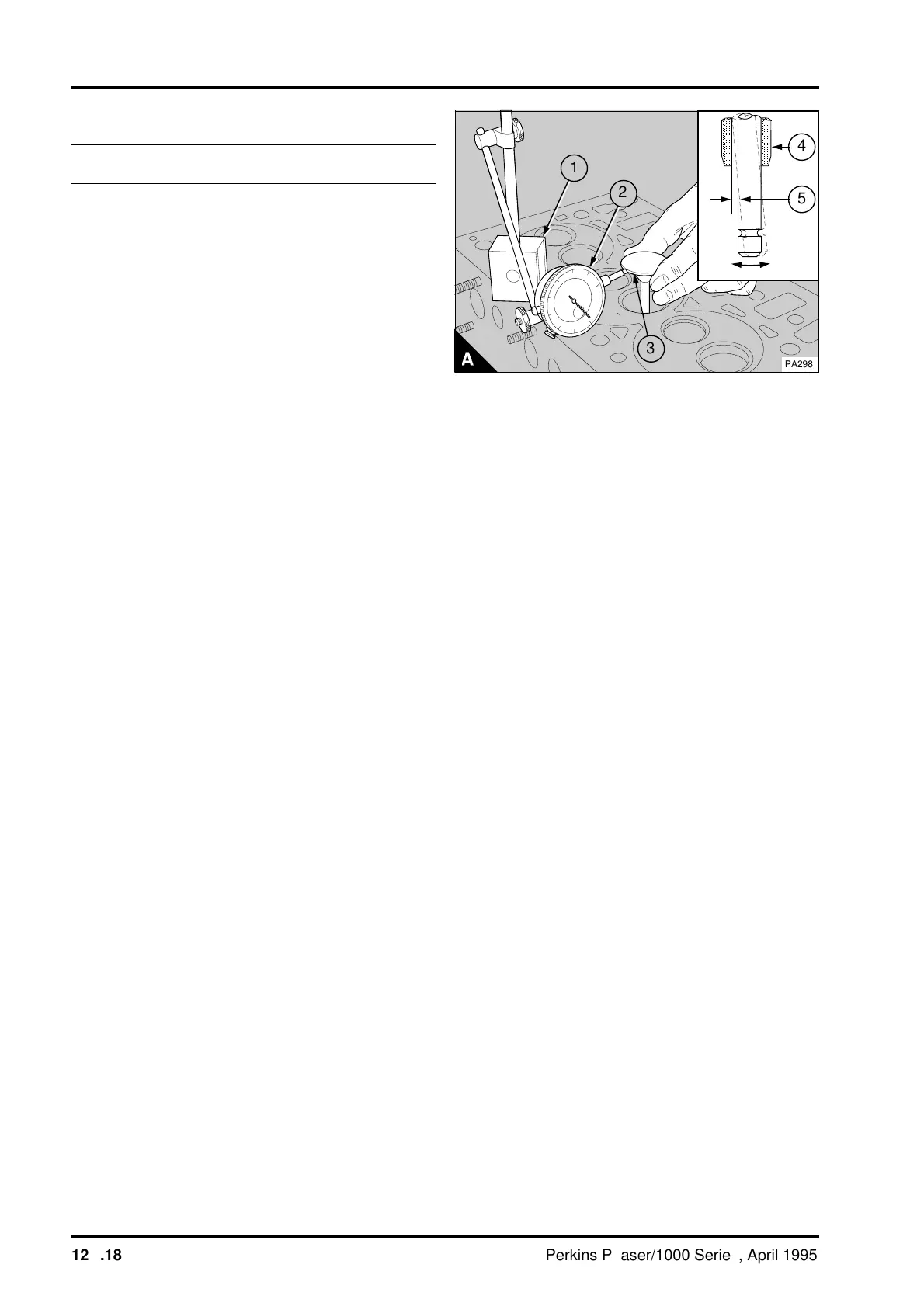

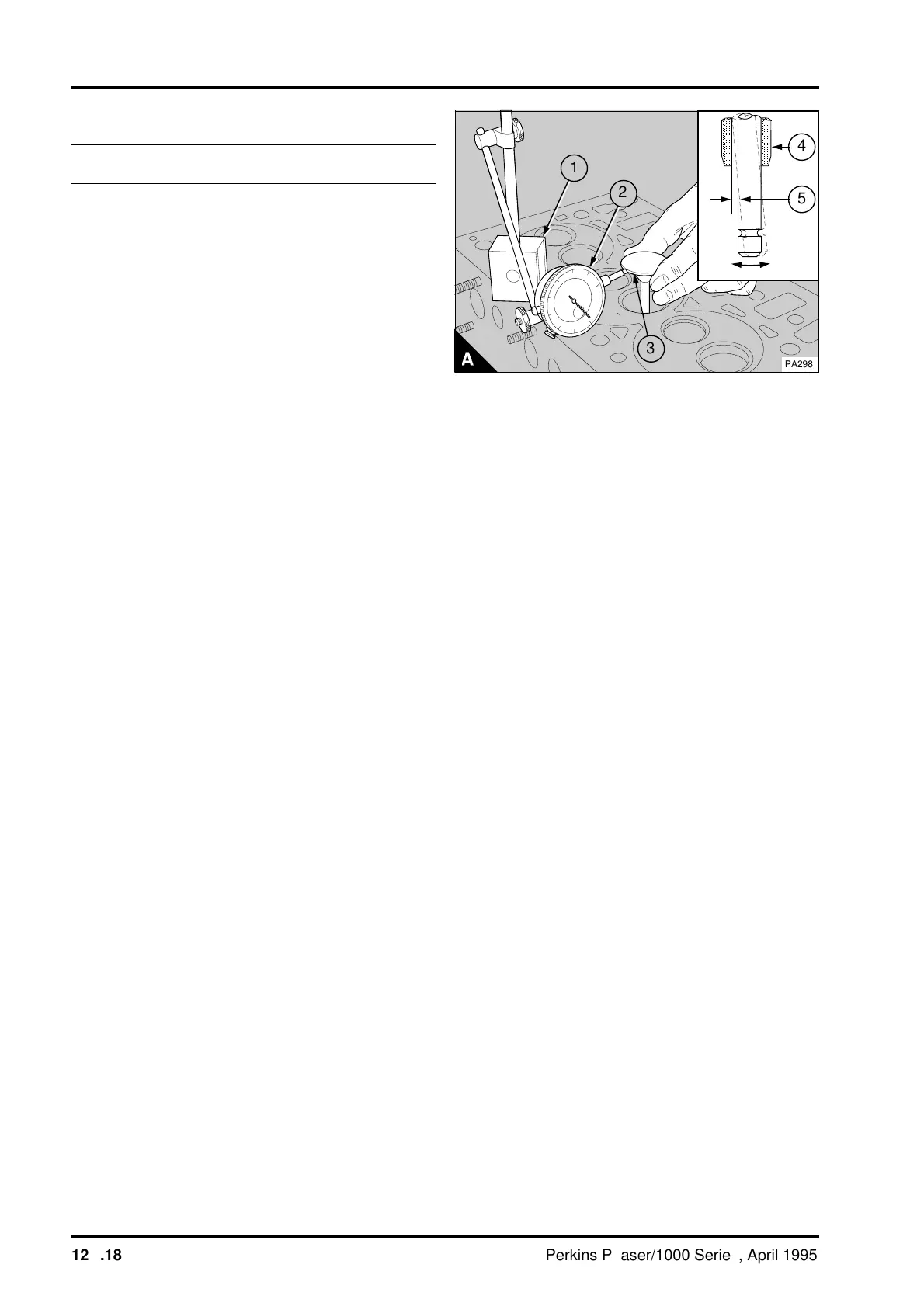

To inspect12A-10

To check the valve guides for wear: The maximum

clearance (A5), between the valve stem and the

bore of the guide is 0,13 mm (0.005 in) for inlet

valves and 0,15 mm (0.006 in) for exhaust valves. If

the clearance, with a new valve fitted, is more than

the limit, then a new valve guide (A4) must be

fitted.

It is recommended that the procedure given below

is used to check the valve guide clearance:

1 Put a new valve in the valve guide.

2 Put a dial test indicator with a magnetic base

(A1) onto the face of the cylinder head

3 With the valve lifted 15,0 mm (0.6 in) and the

gauge (A2) in contact with the edge of the valve

head (A3), move the valve radially away from the

gauge. With the valve held in this position, set the

gauge zero.

4 Move the valve radially across the axis of the

cylinder head towards the gauge. Make a note of

the reading on the gauge. If the reading is equal to

or greater than the data given below, a new valve

guide (A4) must be fitted.

Maximum permissible clearance with a valve lift of

15,0 mm (0.6 in) :

• Inlet guide 0,24 mm (0.009 in)

• Exhaust guide 0,32 mm (0.013)

a

a

5

a

a

4

a

a

a

1

a

a

2

PA298

3

12A.18 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...