14 CRANKSHAFT ASSEMBLY

Rear oil seal assembly - engines which

have the standard seal

To remove and to fit14A-02A

Special tools:

Replacer tool for rear oil seal, PD.145D

Consumable products:

POWERPART Threadlock

POWERPART Silicone rubber sealant

1 Remove the drive components from the rear end

of the engine.

2 Remove the flywheel and the flywheel housing,

see section 22.

3 Remove the setscrews and the cap screws from

the housing and remove the housing and seal

assembly.

4 Inspect the seal for wear or for damage to the

main lip and renew the seal, if necessary. If there is

only a small scratch across the lip, renew the seal.

5 Clean the faces of the cylinder block, the oil seal

housing and the crankshaft flange.

6 Check that the seal and the outer circumference

of the crankshaft flange are not damaged. Where a

new seal has been fitted, check that it is in the

correct position in the housing.

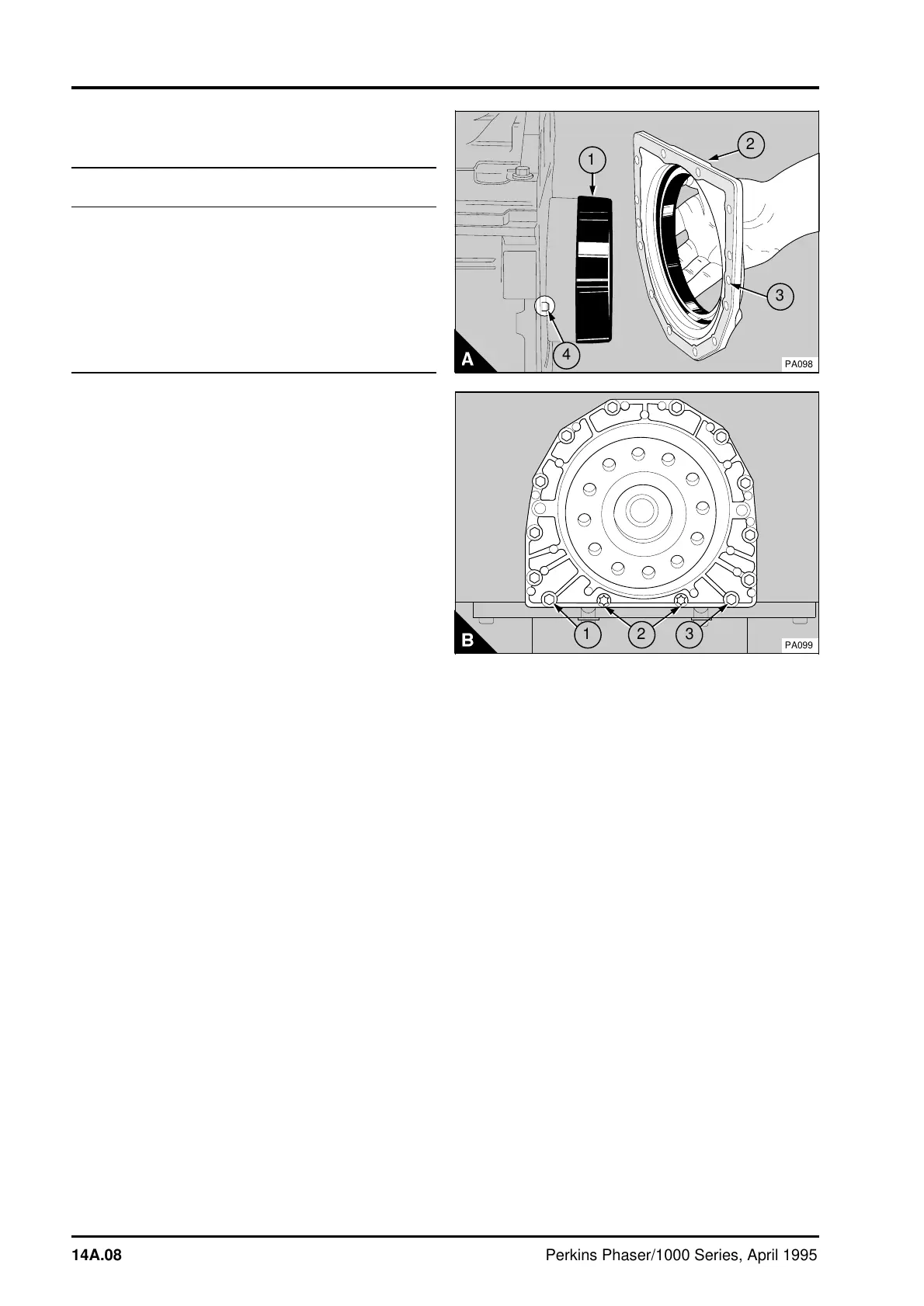

7 Ensure that the two dowels (A4) are fitted in the

cylinder block. Put a new joint (A3) in position on

the dowels, no jointing compound is necessary.

8 Put the seal replacer tool on the crankshaft

flange. Lubricate the crankshaft flange, the main lip

of the seal and the seal replacer tool with clean

engine lubricating oil. The lubrication of the seal is

necessary to prevent damage to the seal when the

engine is first started.

9 Put the seal and housing (A2) on the replacer

tool (A1) and carefully push the assembly into

position on the crankshaft flange and onto the

dowels. Remove the tool, fit the setscrews and the

cap screws. Tighten the setscrews to 22 Nm (16 lbf

ft) 2,2 kgf m and tighten the cap screws to 18 Nm

(13 lbf ft) 1,9 kgf m.

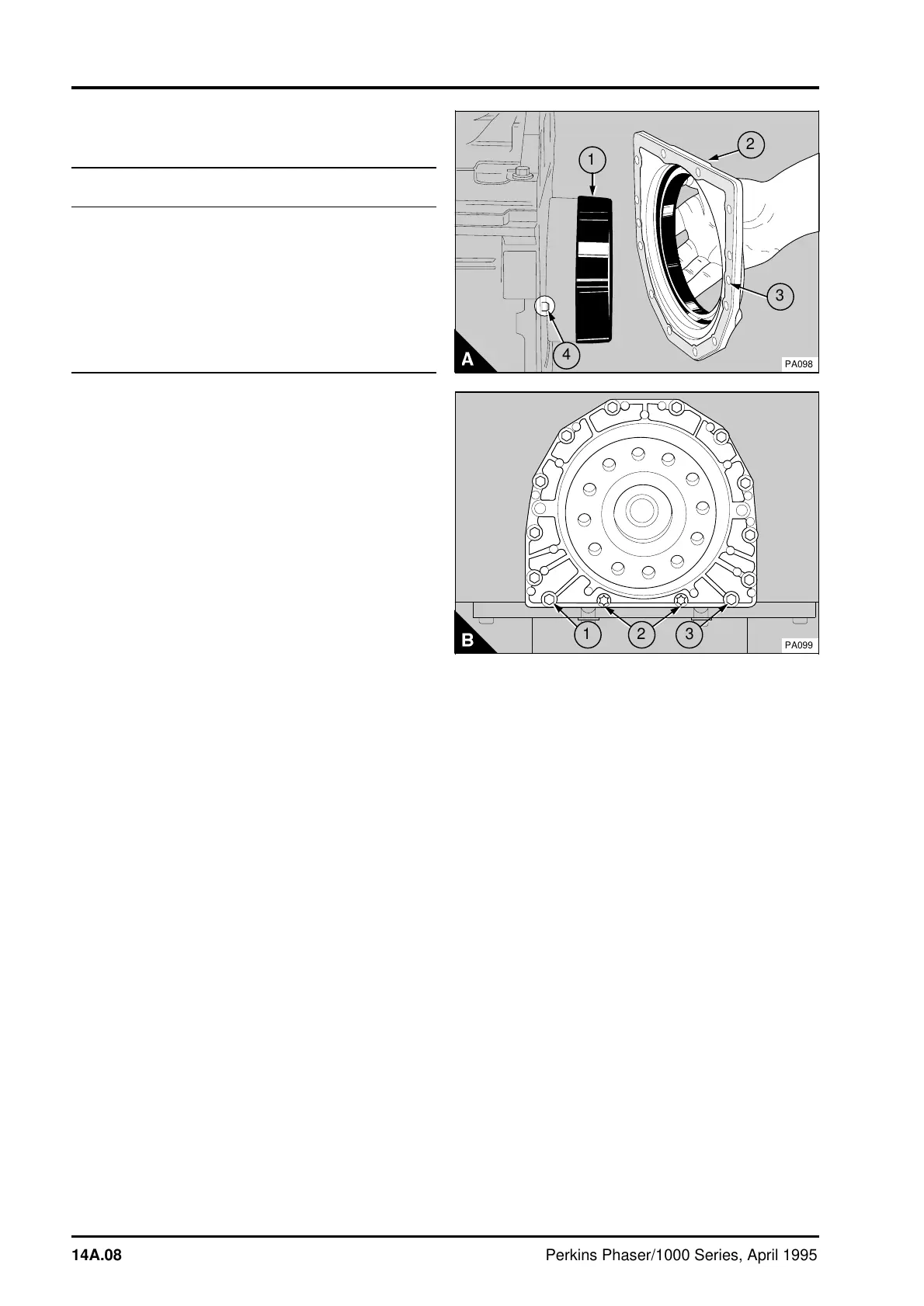

Note: On the latest engines two torx screws (B2)

are fitted instead of cap screws. Tighten the torx

screws to 22 Nm (16 lbf ft) 2,2 kgf m. Two extra

setscrews (B1 and B3) have also been fitted to later

engines.

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

4

a

a

1

3

PA098

2

PA099

a

a

2

a

a

3

a

a

1

14A.08 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...