16 CYLINDER BLOCK ASSEMBLY

To remove and to fit16A-05

Special tools:

Remover/replacer for cylinder liner (main tool),

PD.150B

Adaptors for use with PD.150B, PD.150B-17

Depth gauge, liner flange, PD.41D

Dial gauge for use with PD.41D, PD.208

Consumable products: (See Section 10)

POWERPART Retainer (oil tolerant)

Loctite Safety Solvent or a similar product

Where several liners are to be removed or a very

tight production liner is fitted, a press should be

used. Where a single liner is to be removed or the

crankshaft is to remain in position, a tool for hand

operation is available.

To remove

1 Drain the lubricating oil and remove the

lubricating oil sump, operation 19A-03.

2Remove the cylinder head assembly, operation

12A-07.

3 Remove the piston and connecting rod

assembly, see operation 13A-03.

4 Carefully remove the piston cooling jet, where

fitted, operation 13A-09.

5 Rotate the crankshaft to give access to the

cylinder liner. Protect the crank pin.

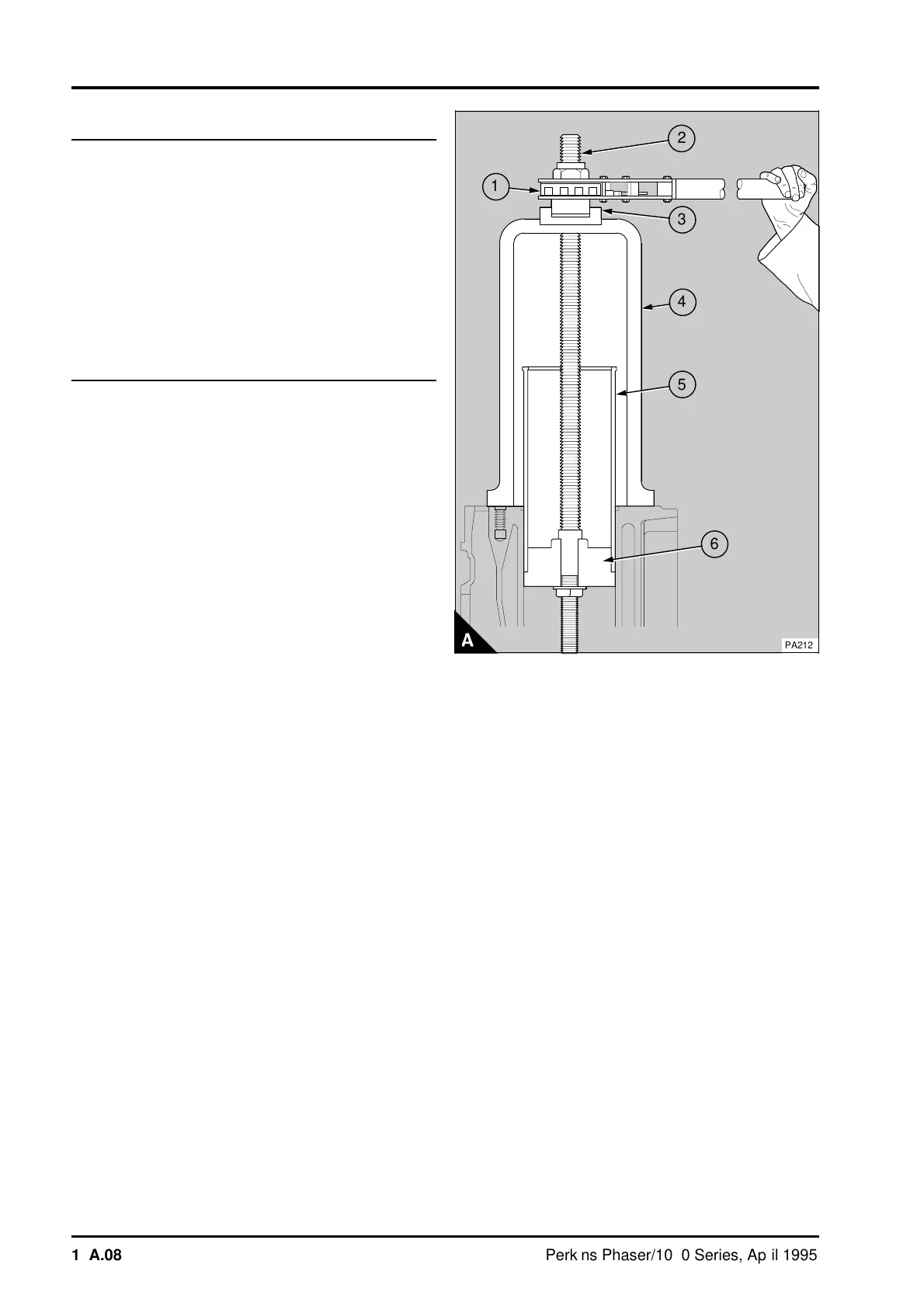

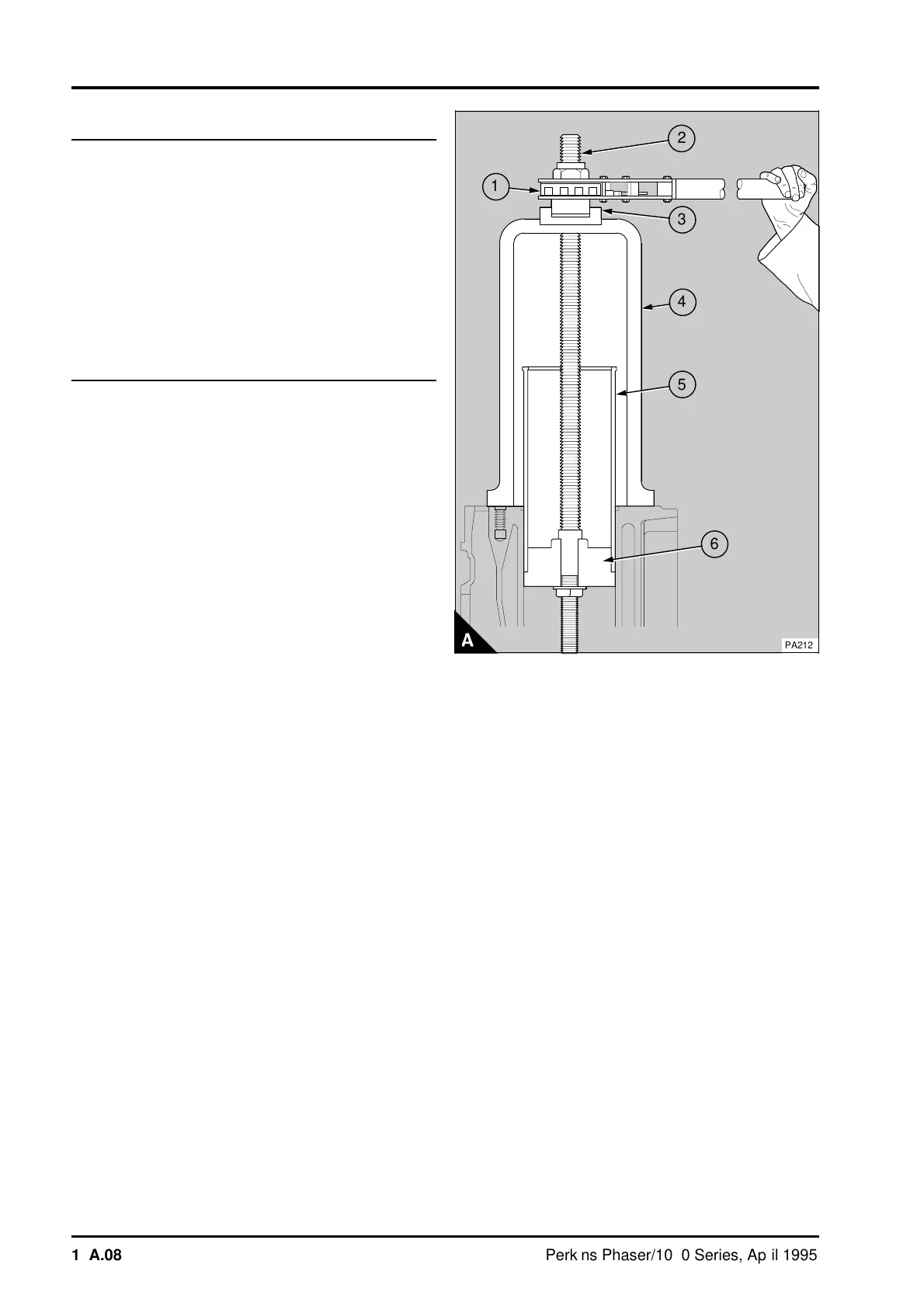

6 Put the tool (A4) on the top face of the cylinder

block and over the centre of the liner (A5). Ensure

that the base of the tool is not on top of the liner

flange of the next cylinder.

7 Put the bearing (A3) in the recess in the top of

the tool with the flat face of the bearing to the

bottom of the recess.

8 Fit the threaded rod (A2) through the bearing and

the top of the tool until the handle (A1) is in the

recess in the top of the bearing. In this position

adjust the threaded rod until the end is below the

bottom of the cylinder liner. Fit the adaptor

PD.150B-17/1 (A6) onto the threaded rod and

against the bottom of the cylinder liner. Ensure that

the two lugs on the top of the adaptor engage with

the flats on the threaded rod. Fit the washer and

nut and tighten the nut onto the adaptor.

9 Lubricate the ratchet of the handle and the

threaded rod with Shell Spirax oil or an equivalent

oil. Operate the handle and pull the cylinder liner

out of the top of the cylinder block.

a

a

2

1

a

a

3

a

a

4

a

a

5

6

PA212

16A.08 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...