CYLINDER BLOCK ASSEMBLY 16

To fit a service liner

A service liner is a transition fit of +/- 0,03 mm

(+/- 0.001 in) in the parent bore. A special tool will

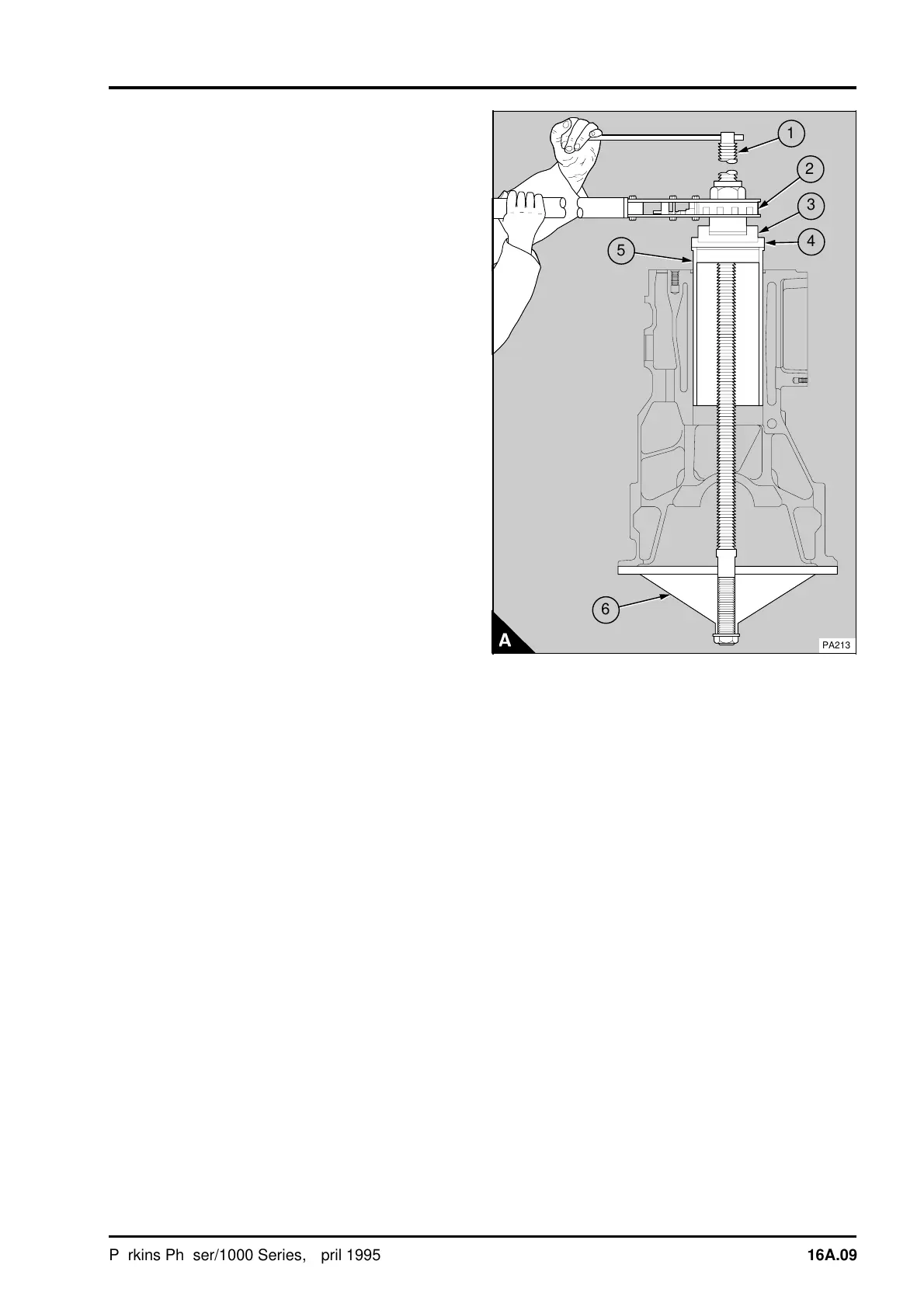

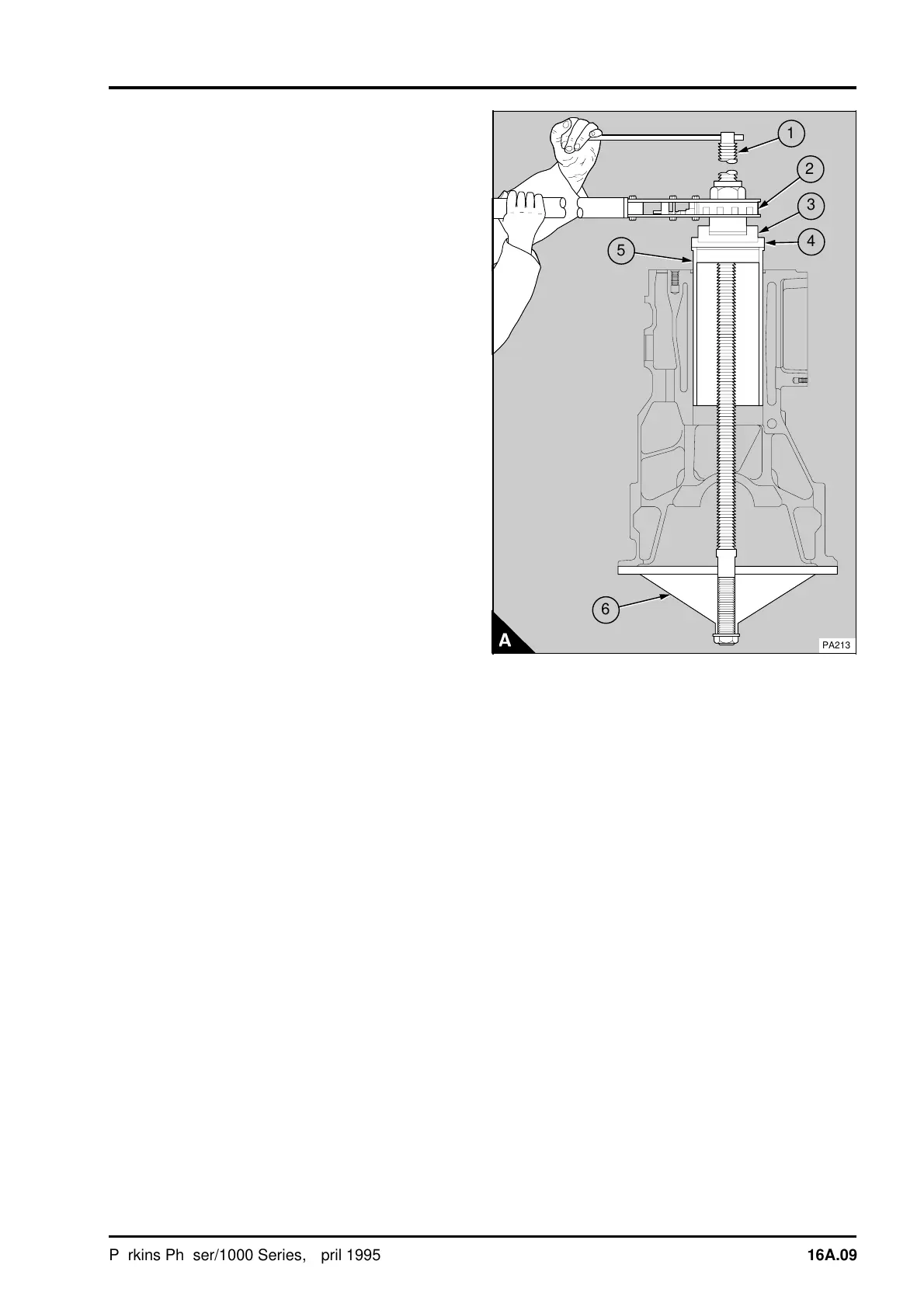

not be necessary to fit some liners, but where a

liner is a tight fit, tool PD.150B can be used.

Caution: Do not hit a liner with a hammer.

1 Clean thoroughly the parent bore. Clean the top

50 mm (2.0 in) and the recess for the liner flange

with Loctite Safety Solvent or a similar product; use

it in accordance with the manufacturer's

instructions.

2 Clean thoroughly the outer surface of the liner

with Loctite Safety Solvent.

3 Lubricate lightly the parent bore with clean

engine lubricating oil, except for the top 50 mm

(2.0 in).

4 Engage the cylinder liner (A5) into the parent

bore; ensure that the liner is vertical. Put the

adaptor PD.150B-17/2 (A4) onto the top of the liner

with the shoulder of the adaptor on the liner flange.

Put the bearing (A3) into position in the recess in

the top of the adaptor with the flat face of the

bearing to the bottom of the recess.

5 Fit the threaded rod (A1) through the bearing, the

adaptor and the liner until the handle is against the

recess in the bearing. In this position adjust the

threaded rod until the end is below the bottom face

of the cylinder block.

6 Fit the adaptor PD.150B/6 (A6) onto the threaded

rod; ensure that the flat face of the adaptor is

against the bottom face of the cylinder block. Fit the

washer and the nut; ensure that the threaded rod is

in the centre of the liner and tighten the nut onto

the adaptor.

a

a

1

2

3

4

a

a

a

5

a

a

6

PA213

Perkins Phaser/1000 Series, April 1995 16A.09

Loading...

Loading...