PISTON AND CONNECTING ROD ASSEMBLIES 13

Connecting rod

To inspect13A-07

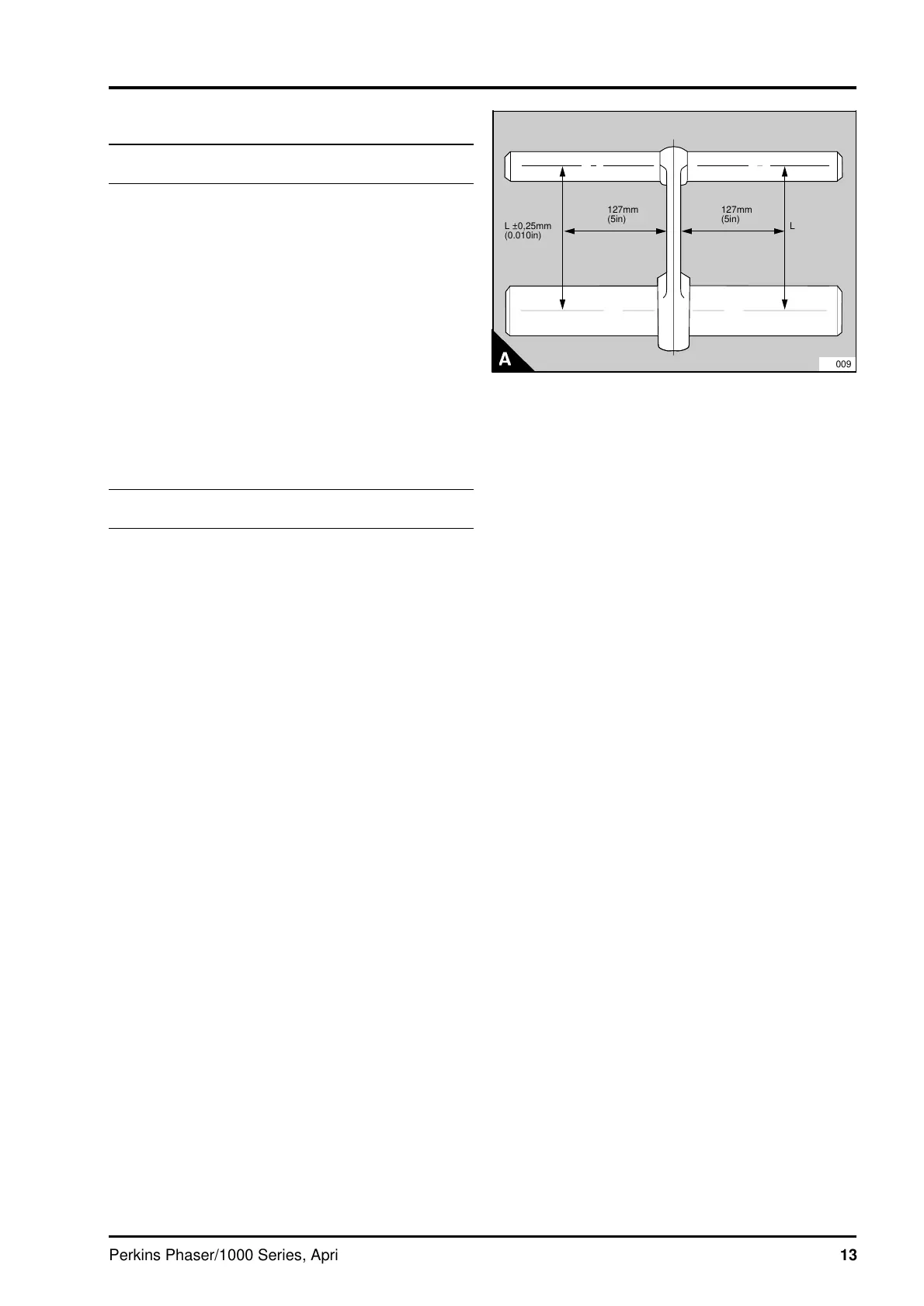

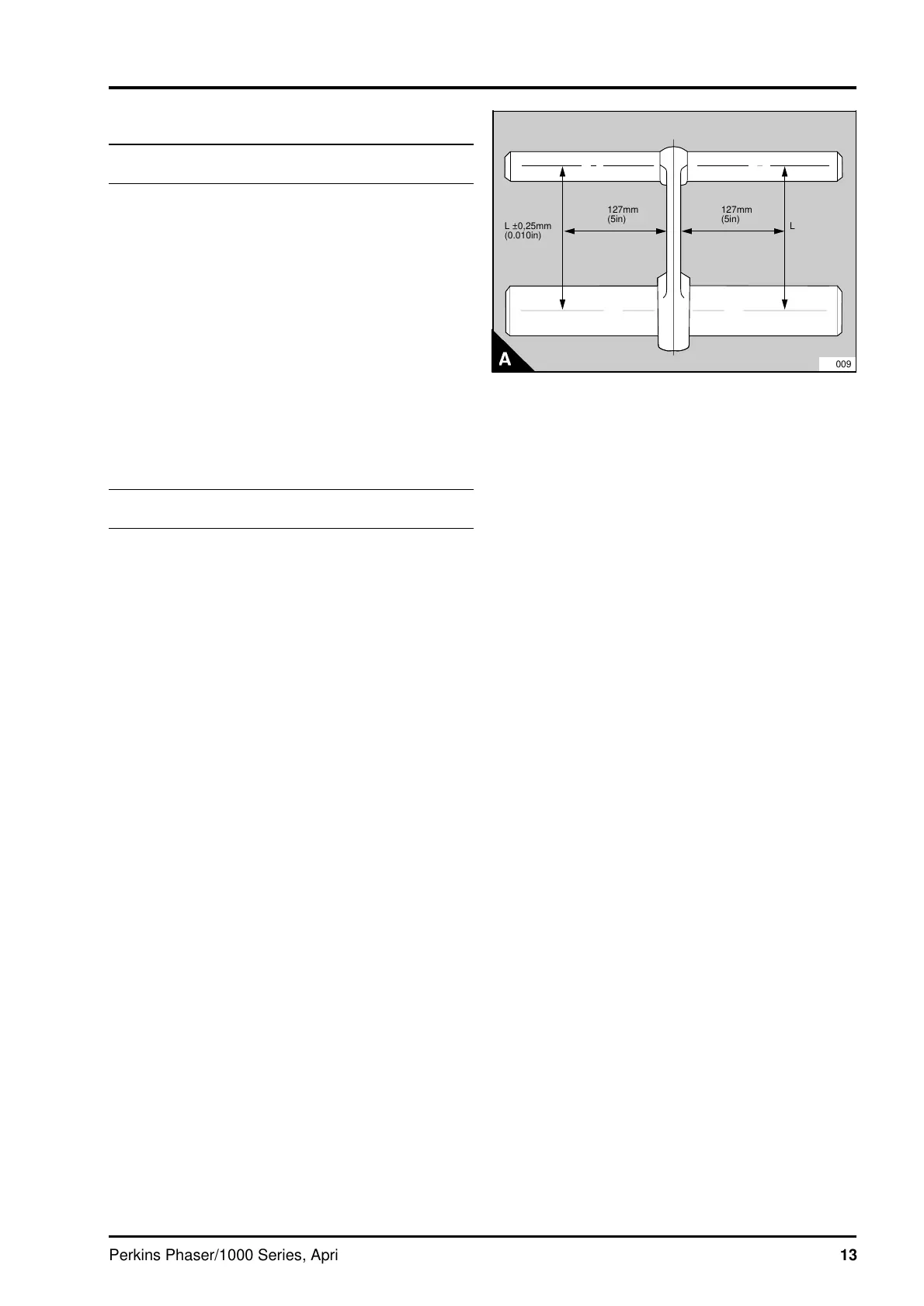

1 Check the connecting rod for distortion (A).

Note: The large and small end bores must be

square and parallel with each other within the limits

of +/- 0,25 mm (0.010 in) measured 127 mm

(5.0 in) each side of the connecting rod axis on a

test mandrel. With the small end bush fitted, the

limits are reduced to +/- 0,06 mm (0.0025 in).

2 Check the small end bush for wear or for other

damage and renew it, if necessary.

3 Check the fit of the gudgeon pin in the small end

bush and check the gudgeon pin for wear, see the

data and dimensions.

Small end bush

To remove and to fit13A-08

1 Press out the old bush with a suitable adaptor.

2 Clean the connecting rod bore and remove any

sharp edges.

3 Press in the new bush. Ensure that the

lubrication hole in the bush is on the same side as,

and is aligned with, the hole in the top of the

connecting rod.

4 Ream the bush to get the correct clearance

between the gudgeon pin and the bush, see the

data and dimensions.

Note: On turbocharged engines the small end is

wedge shaped. After the small end bush has been

fitted, machine the bush to the shape of the small

end and remove any sharp edges.

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

L ±0,25mm

(0.010in)

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

127mm

(5in)

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

127mm

(5in)

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

L ±0,25mm

(0.010in)

PG009

Perkins Phaser/1000 Series, April 1995 13A.13

Loading...

Loading...