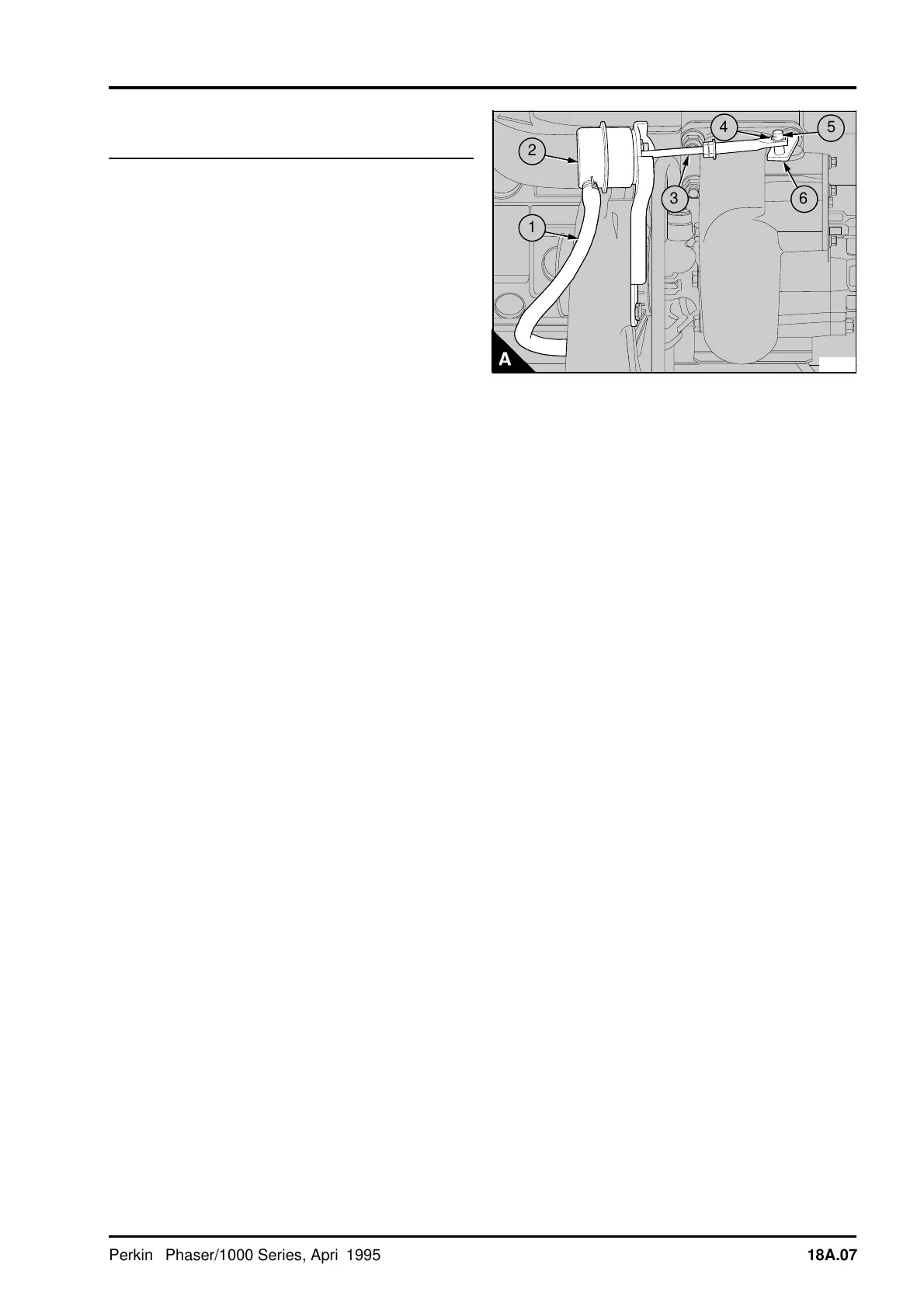

ASPIRATION SYSTEM 18

To remove and to fit the actuator

assembly of the waste-gate unit18A-03

It is important that the waste-gate actuator setting is

not altered. Do not remove the actuator or

mounting bracket unless it is necessary to renew

the actuator assembly.

If a waste-gate actuator or mounting bracket

assembly is removed from a turbine or compressor

housing it is important that the bracket is fitted into

the correct position on the housing.

To remove

1 Disconnect the boost sensor pipe (A1) at the

actuator (A2).

2 Remove the clip (A4) which retains the actuator

rod (A3) and lift the end of the actuator rod off the

pin (A5) of the waste-gate valve.

3 Release the setscrews which retain the actuator

bracket to the turbocharger and remove the

actuator and bracket assembly.

To fit

1 Put the actuator and bracket assembly in position

on the turbocharger and tighten the setscrews.

2 Connect to the actuator (A2) an air supply which

can be adjusted accurately and is fitted with an

accurate gauge.

3 Operate the arm (A6) of the waste-gate valve by

hand to check that the valve is free to move.

4 Push the arm of the waste-gate valve as far as

possible toward the actuator and hold the arm in

this position. Slowly apply air pressure to the

actuator until the end of the actuator rod (A3) will fit

easily onto the pin (A5) of the waste-gate valve. Fit

the clip (A4). Release the air pressure.

Caution: Do not apply an air pressure of more than

205 kPa (30 lbf/in

2

) 2,1 kgf/cm

2

to the actuator.

Higher pressures may damage the actuator.

5 Check the operation of the waste-gate unit,

operation 18A-04.

PA184

a

a

4

a

a

5

a

a

2

a

a

a

1

a

a

6

3

Perkins Phaser/1000 Series, April 1995 18A.07

Loading...

Loading...