19 LUBRICATION SYSTEM

To inspect19A-07

If any part is worn enough to have an effect on the

performance of the oil pump, the complete oil pump

must be renewed.

1 Release the setscrews and remove the cover of

the oil pump. For pumps which are fitted to a

balancer unit, remove the single setscrew and the

cover.

2 Remove the outer rotor and clean thoroughly all

the parts. Check for cracks and any other damage.

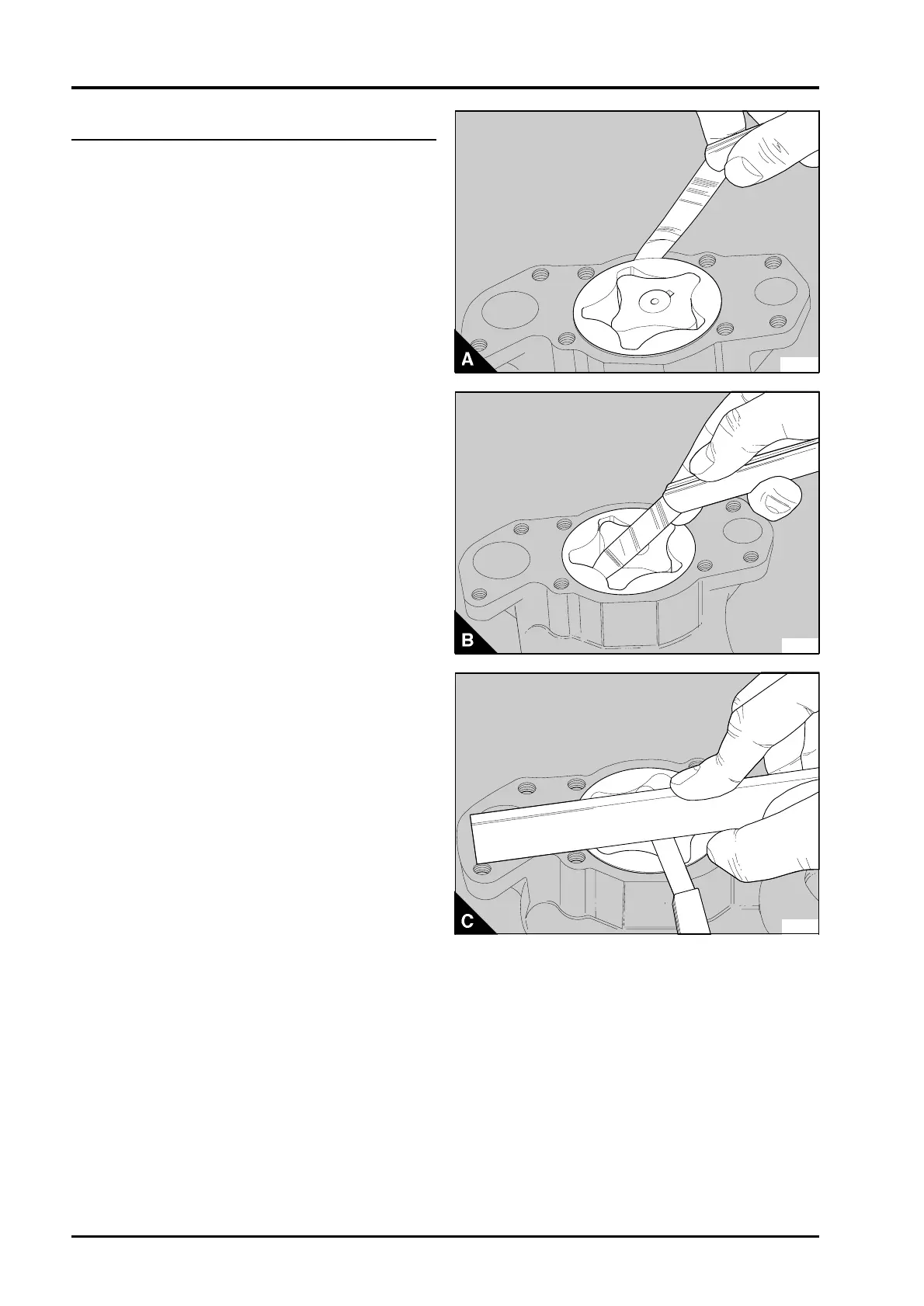

3 Fit the outer rotor and check the outer rotor to

body clearance (A).

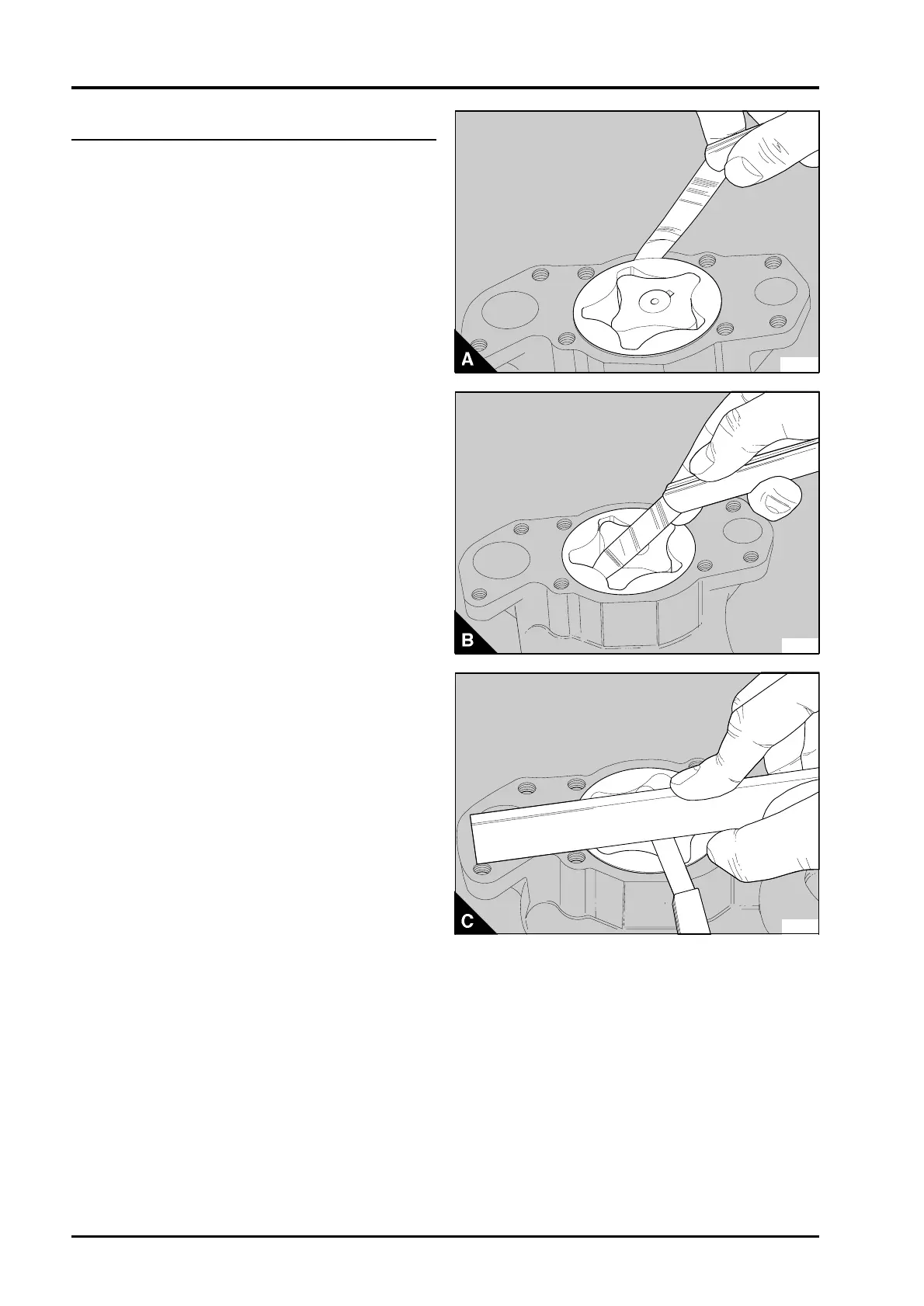

4 Check the inner rotor to outer rotor clearance

(B).

5 Check the rotor end-float with a straight edge

and a feeler gauge (C). For all the above

clearances, see the data and dimensions.

6 Clean the top face of the oil pump and the

bottom face of the cover and fit the cover. Tighten

the setscrews to 28 Nm (21 lbf ft) 2,9 kgf m. For

pumps which are fitted to a balancer unit, put the

cover in position and tighten the single setscrew to

22 Nm (16 lbf ft) 2,2 kgf m.

PA234

PA235

PA236

19A.16 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...