20A FUEL SYSTEM

Fuel system

To eliminate air from the fuel system -

Bosch pump20A-08

If air enters the fuel system, it must be removed

from the system before the engine can be started.

Air can enter the system if:

• The fuel tank is drained during normal operation.

• The low-pressure fuel pipes are disconnected.

• A part of the low-pressure fuel system leaks

during engine operation.

In order to remove air from the fuel system,

proceed as follows:

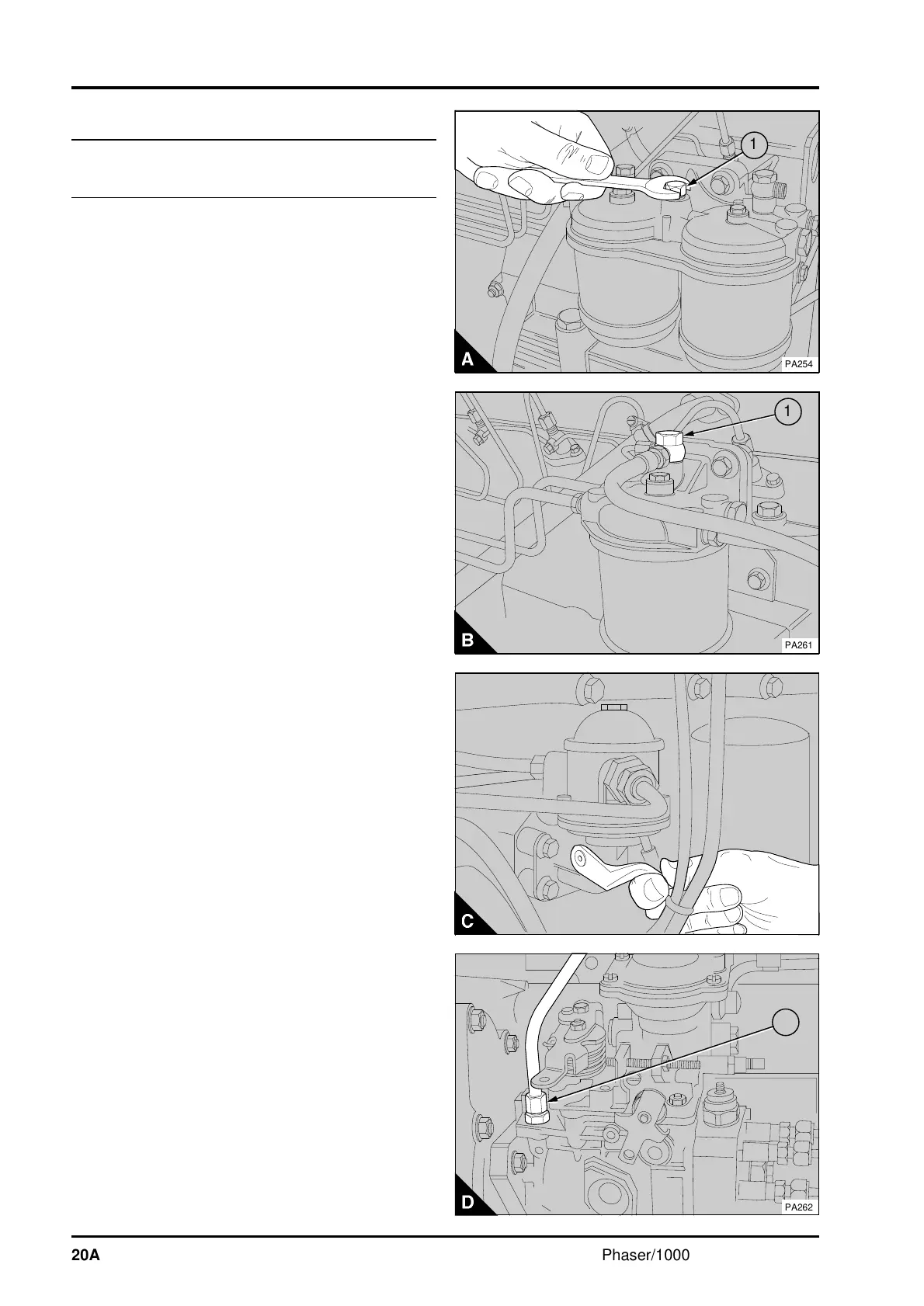

1 Loosen the vent plug (A1) on top of the twin

element fuel filter (A) by two or three turns. If a

single element filter is used, loosen the banjo

connection bolt (B1) which is fitted on the top of the

filter (B).

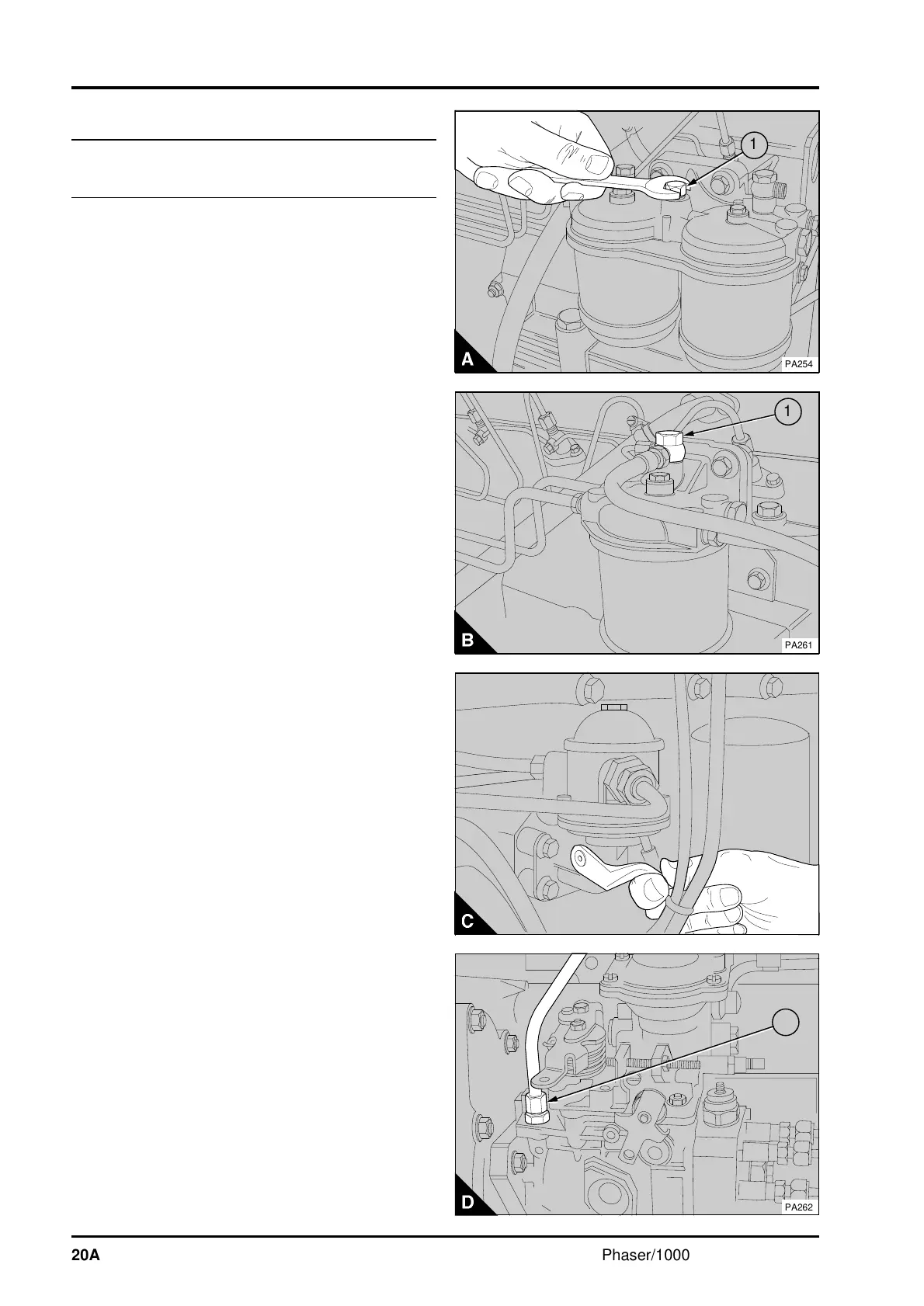

2 Operate the priming lever on the fuel lift pump

(C) until fuel, free of air, comes from the filter vent

point. Tighten the vent plug or the banjo connection

bolt. If the drive cam of the fuel lift pump is at the

point of maximum cam lift, it will not be possible to

operate the priming lever. In this situation, the

crankshaft must be rotated one revolution.

3 Ensure that the manual stop is in the "run"

position. If an electrical stop control is used, turn

the key of the start switch to the "R" position.

4 Loosen the union nut of the fuel inlet pipe (D1).

Operate the priming lever of the fuel lift pump until

fuel, free of air, comes from the loose connection.

Tighten the union nut.

a

a

1

PA254

1

PA261

PA015

a

a

20A.20 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...