19 LUBRICATION SYSTEM

To dismantle and to assemble19A-09

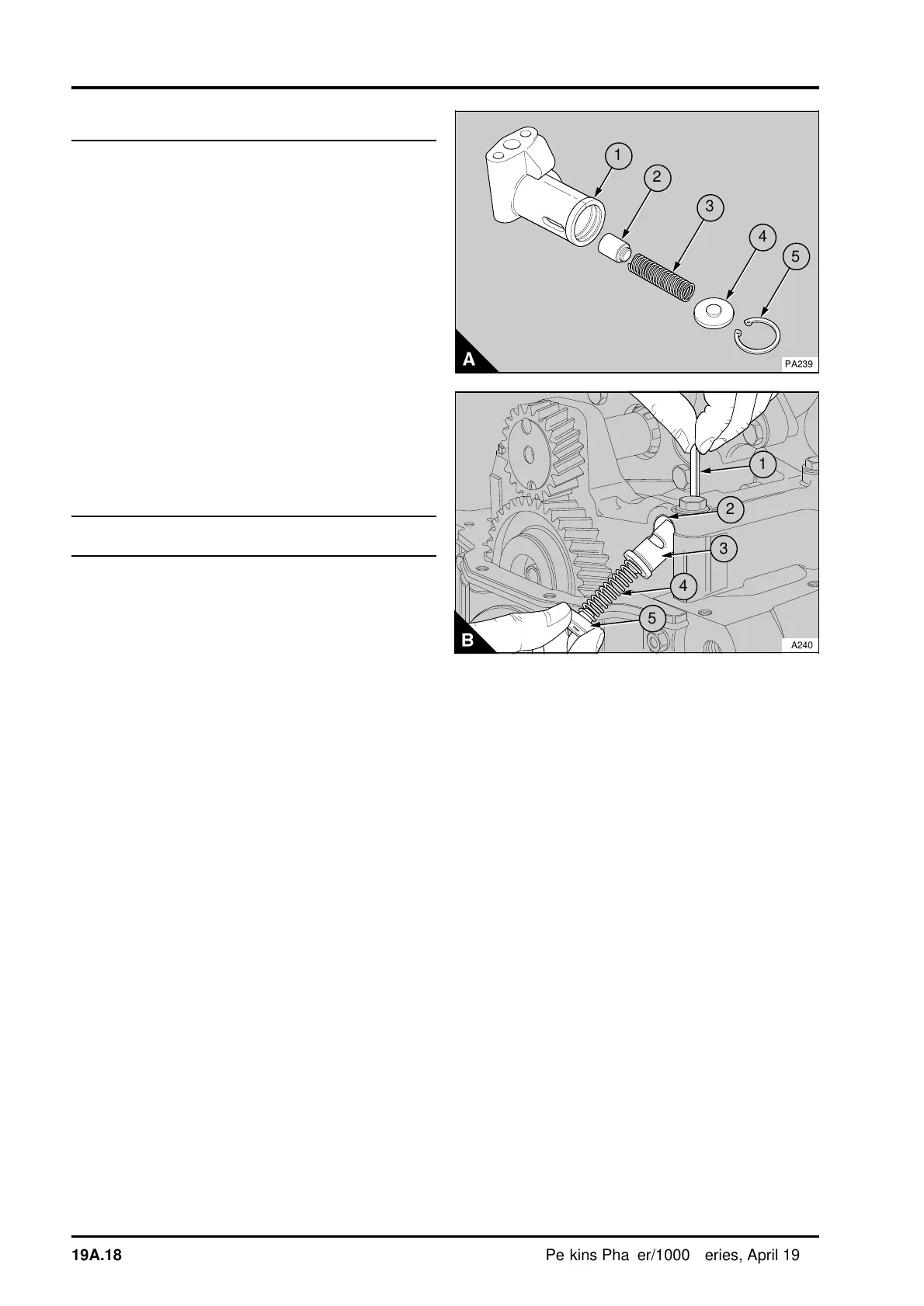

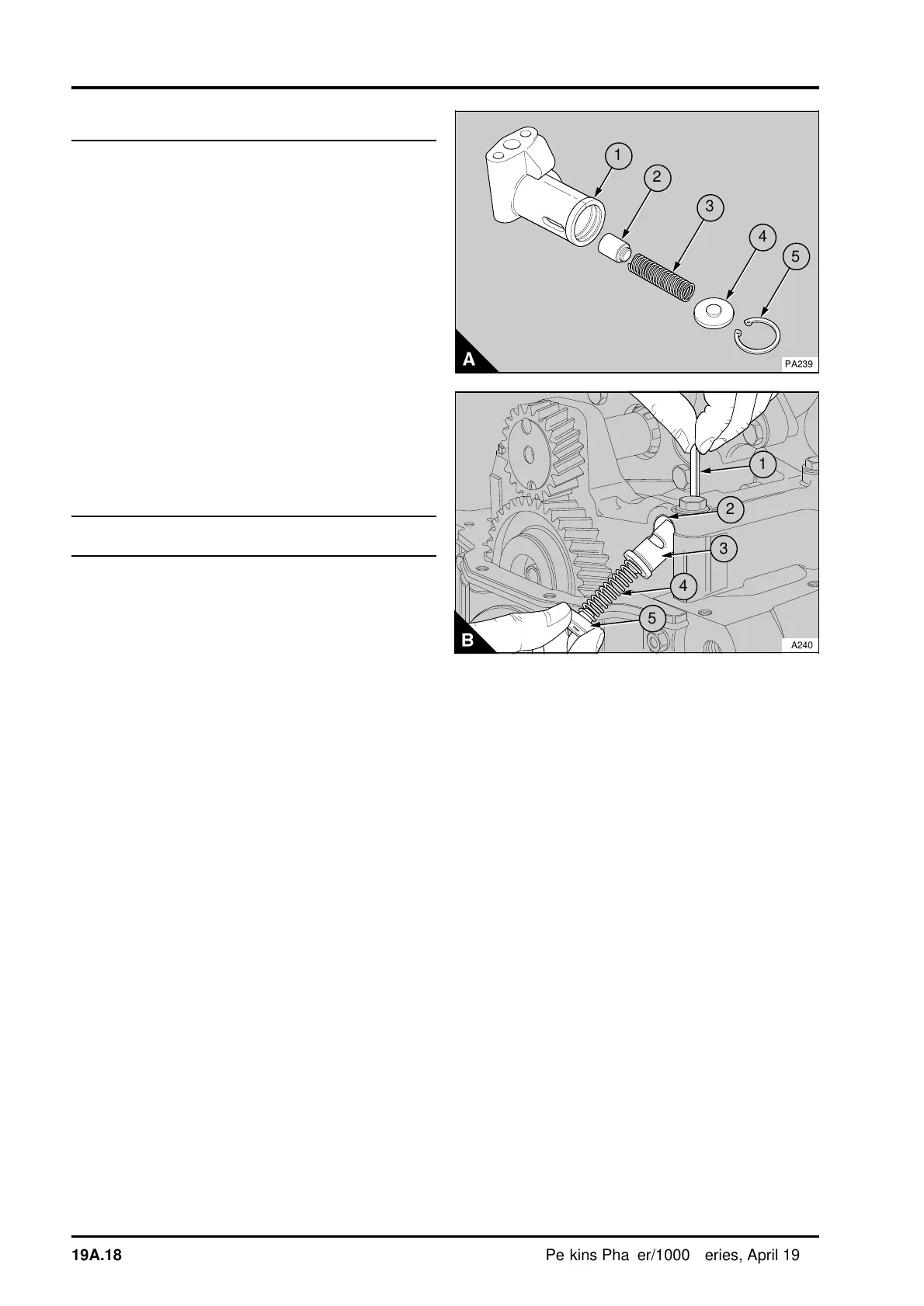

If necessary, the relief valve can be dismantled and

assembled while it is fitted to the engine.

1 Apply pressure to the end plate (A4 or B5) of the

spring assembly; release the circlip (A5) or remove

the pin (B1) and carefully release the pressure to

remove the end plate and the spring (A3 or B4)

from the valve body. Remove the plunger

(A2 or B3) from the bore of the body (A1 or B2).

2 Ensure that all the components are cleaned and

then lubricated lightly with clean engine lubricating

oil.

3 Fit the plunger into the bore with its hollow end

to the inside. Fit the spring and the end cap into the

bore with the ends of the spring fitted around the

bosses of the plunger and the end plate. Apply

pressure to the end plate and fit the circlip into its

groove or fit the pin into the holes in the balancer

frame.

To inspect19A-10

Do not try to change the operation pressure of the

relief valve by a method other than the installation

of new components.

1 Check the spring for wear and other damage

and, if possible, check the load necessary to

compress the spring to its fitted length, see the

data and dimensions.

2 Check the plunger for wear and other damage

and ensure that it slides easily in the bore of the

relief valve.

3 Check the body and the end plate for wear and

other damage.

4 Renew worn or damaged components.

a

a

a

1

a

a

2

3

4

a

a

a

5

PA239

1

a

a

2

a

a

a

3

a

a

4

a

a

5

PA240

19A.18 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...