15 TIMING CASE AND DRIVE ASSEMBLY

To fit

1 Ensure that the key is fitted correctly in the fuel

pump shaft. Fit the gear and the spring washer and

loosely fit the nut.

Note: Early Phaser 210Ti engines have a spacer

between the gear and the spring washer.

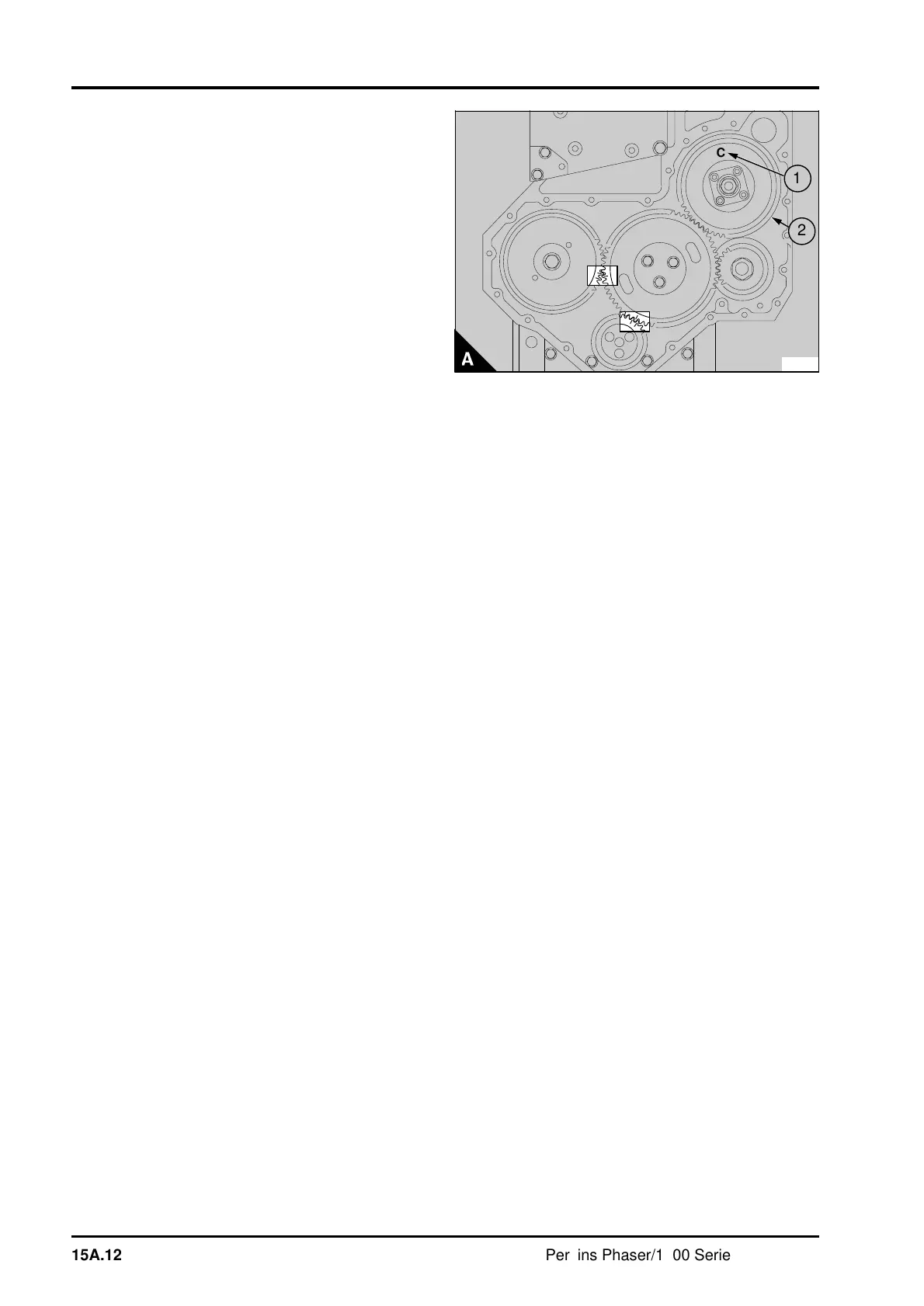

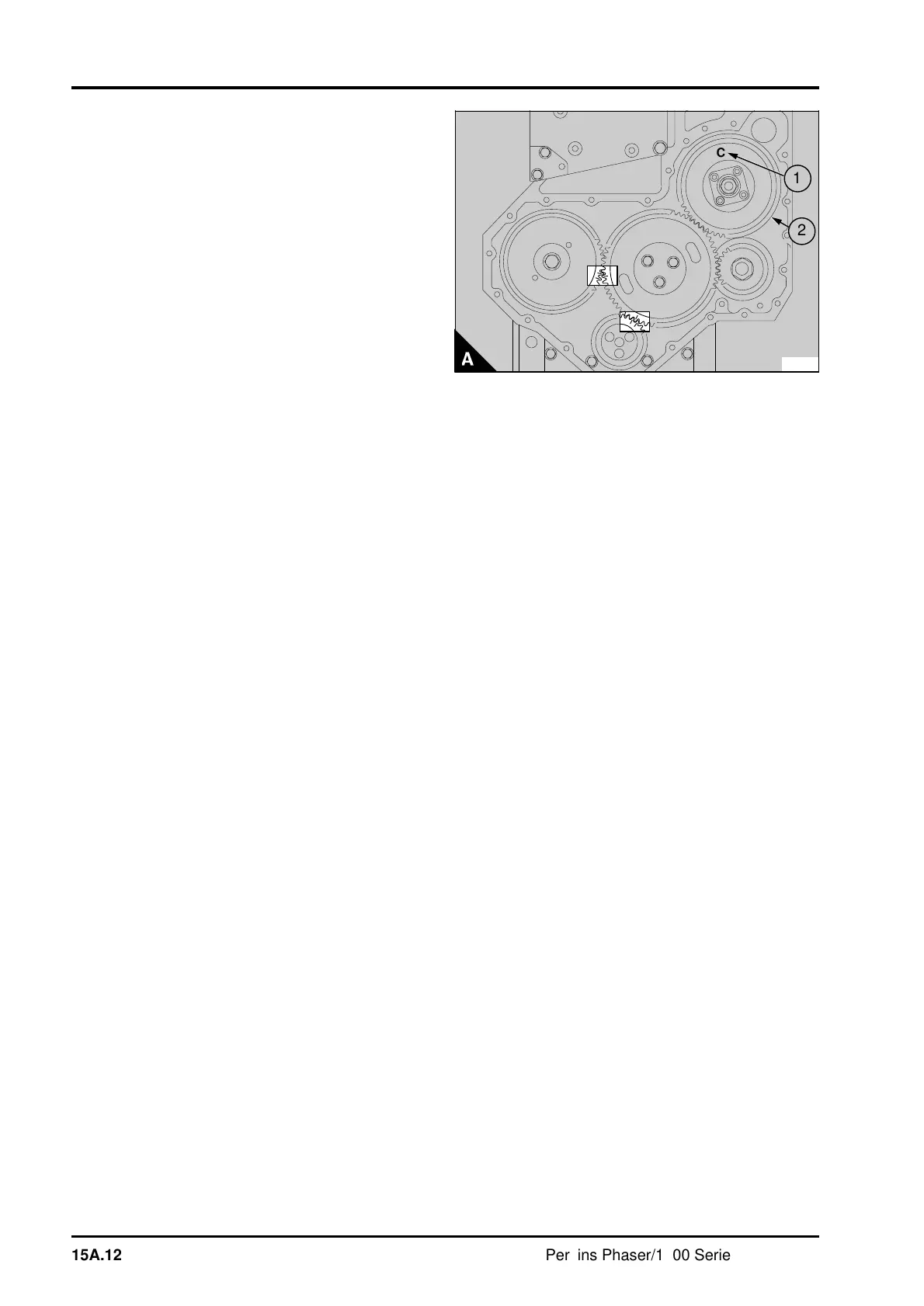

2 Rotate the fuel pump gear (A2) to ensure that

the relevant marked tooth of the fuel pump gear

("4" for four cylinder engines or "6" for six

cylinder engines) will align with the marked teeth of

the idler gear (A). Fit the idler gear, operation

15A-03.

3 Tighten the nut of the fuel pump gear to 80 Nm

(59 lbf ft) 8,2 kgf m. The teeth of the drive gear and

the idler gear should be fully in mesh when the fuel

pump gear is tightened onto the hub of the fuel

injection pump.

Note: On engines fitted with an Bosch MW in-line

fuel injection pump, the pump must be put in the

static timing position, see the data and dimensions,

before the gear is fitted. For early engines: When

the gear is fitted, ensure that the B marked on the

gear is to the front. For the latest engines: Ensure

that the letter C (A1) and the last four digits of the

part number marked on the gear are to the front.

4 If a new gear has been fitted, check the

backlash.

5Fit the timing case cover, operation 15A-01.

6 For gear driven coolant pumps: Fit the coolant

pump, operation 21A-02.

7Fit the crankshaft pulley, operation 14A-01.

8If necessary, fit the fan drive pulley, operation

21A-05.

9Fit the drive belts, operation 23A-03 and adjust

the belt tension, operation 23A-02.

10Fit the fan, operation 21A-04.

11 Fill the cooling system.

PA209

a

a

2

a

a

1

C

15A.12 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...