ENGINE TIMING 17A

To check the timing of the

- Bosch EPVE fuel injection pump17A-03

Special tools:

Timing gauge adaptor, MS.107

Spanner for flange nuts of fuel injection pump,

PD.239

Note: The procedure given below is suitable for

engines fitted with a Bosch EPVE fuel injection

pump and have a static timing of 10° or more.

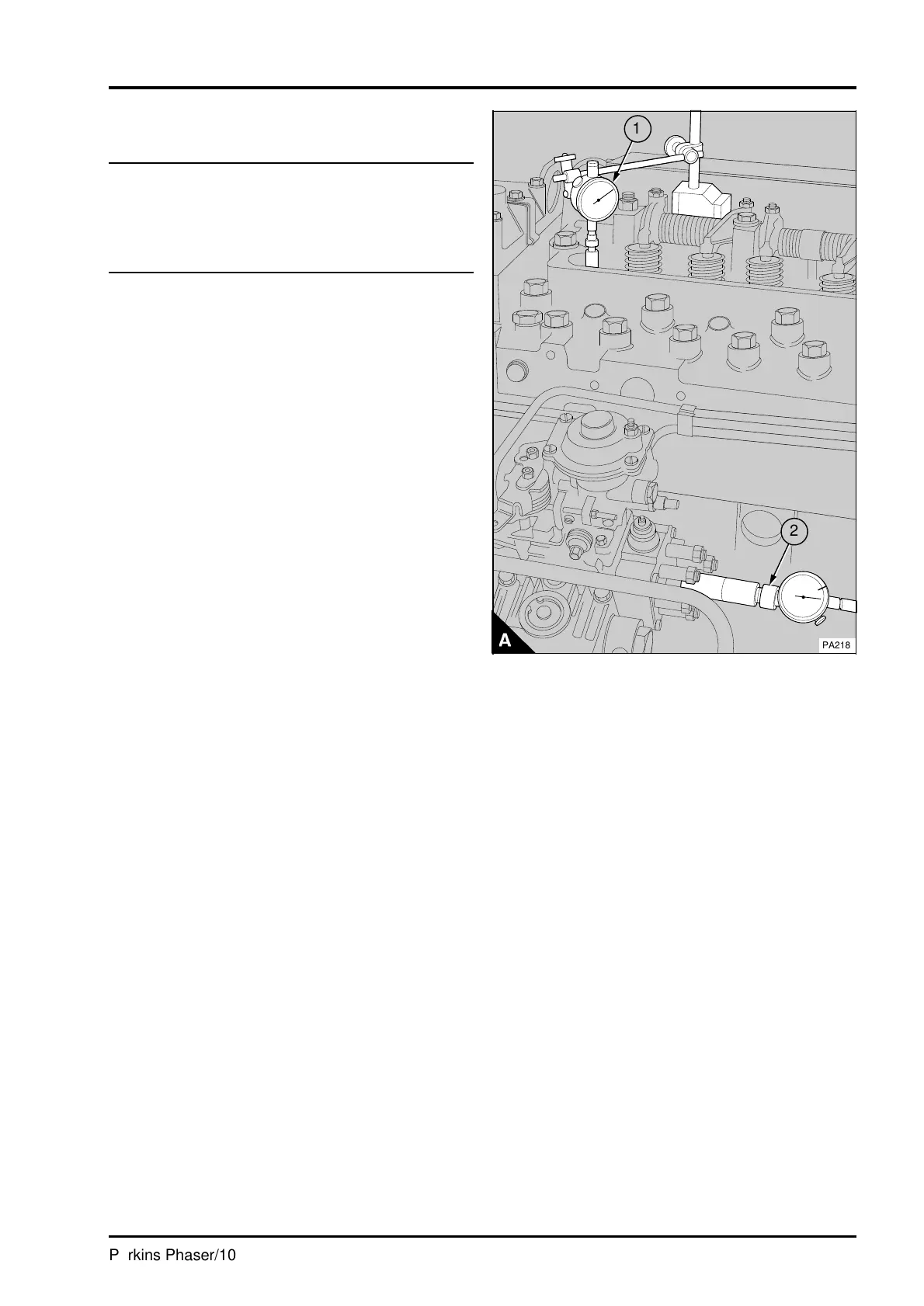

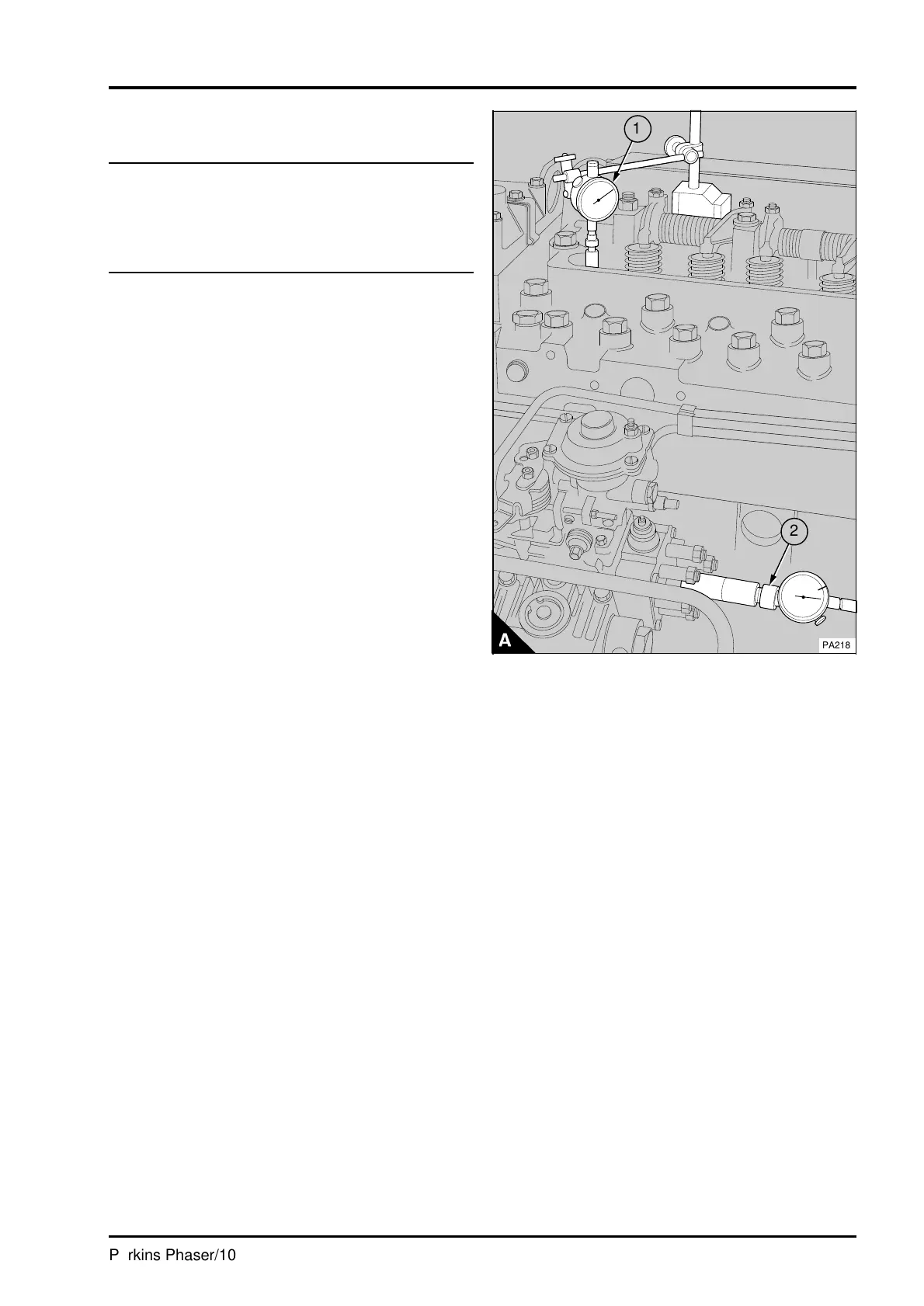

1 Set the piston of number 1 cylinder to TDC on

the compression stroke, operation 17A-01. It is not

necessary to fit a temporary pointer

(17A-01/paragraph 1). Instead, the dial of the dial

test indicator (A1) should be set at zero when the

clockwise movement of the pointer stops

(17A-01/paragraph 7).

2 Remove the high-pressure pipes from the fuel

injection pump. Ensure that a spanner is used to

prevent movement of the pump outlets when the

high-pressure pipes are removed or fitted.

3 Remove the plug and washer from the rear of

the fuel pump and fit the adaptor, number MS.107,

and a suitable dial gauge (A2). Set the dial gauge to

indicate approximately 3,0 mm.

4 Slowly rotate the crankshaft, counter-clockwise

from the front of the engine, until the dial gauge

indicates that the plunger of the fuel injection pump

is at the bottom of its stroke. Set the dial to zero.

5 Slowly rotate the crankshaft clockwise until the

dial gauge on the valve stem indicates the correct

position of the piston before TDC, see data and

dimensions. The timing of the fuel injection pump is

correct if the dial gauge on the pump plunger

indicates 1,0 mm (0.039 in).

6 If the timing is not correct, disconnect the

remainder of the pipes of the fuel injection pump

and loosen the setscrew of support bracket for the

pump.

7 To correct the timing, hold the fuel injection

pump and release the flange nuts; if a compressor

is fitted, it will be necessary to use tool number

PD.239 to release the flange nuts nearest the

cylinder block. If the gauge on the pump plunger

indicates more than 1,0 mm (0.039 in), rotate the

fuel pump counter-clockwise, from the rear of the

fuel pump, until the gauge indication is 1,0 mm

(0.039 in). If the gauge indication is less than

1,0 mm (0.039 in), rotate the fuel pump clockwise

until the gauge indication is 1,0 mm (0.039 in).

Tighten the flange nuts and the setscrew of the

support bracket for the pump.

1

a

a

a

2

PA218

Perkins Phaser/1000 Series, April 1995 17A.05

Loading...

Loading...