20A FUEL SYSTEM

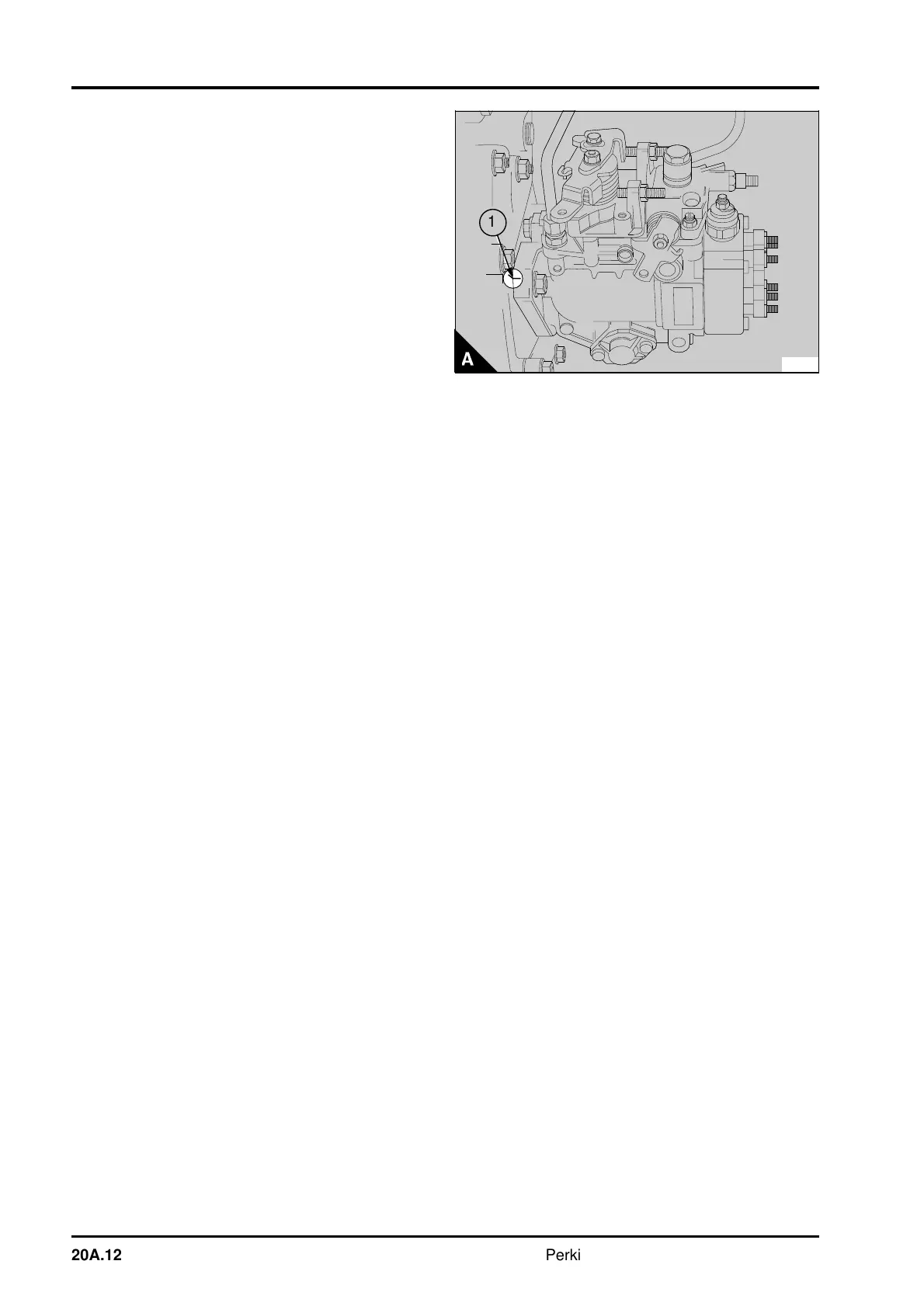

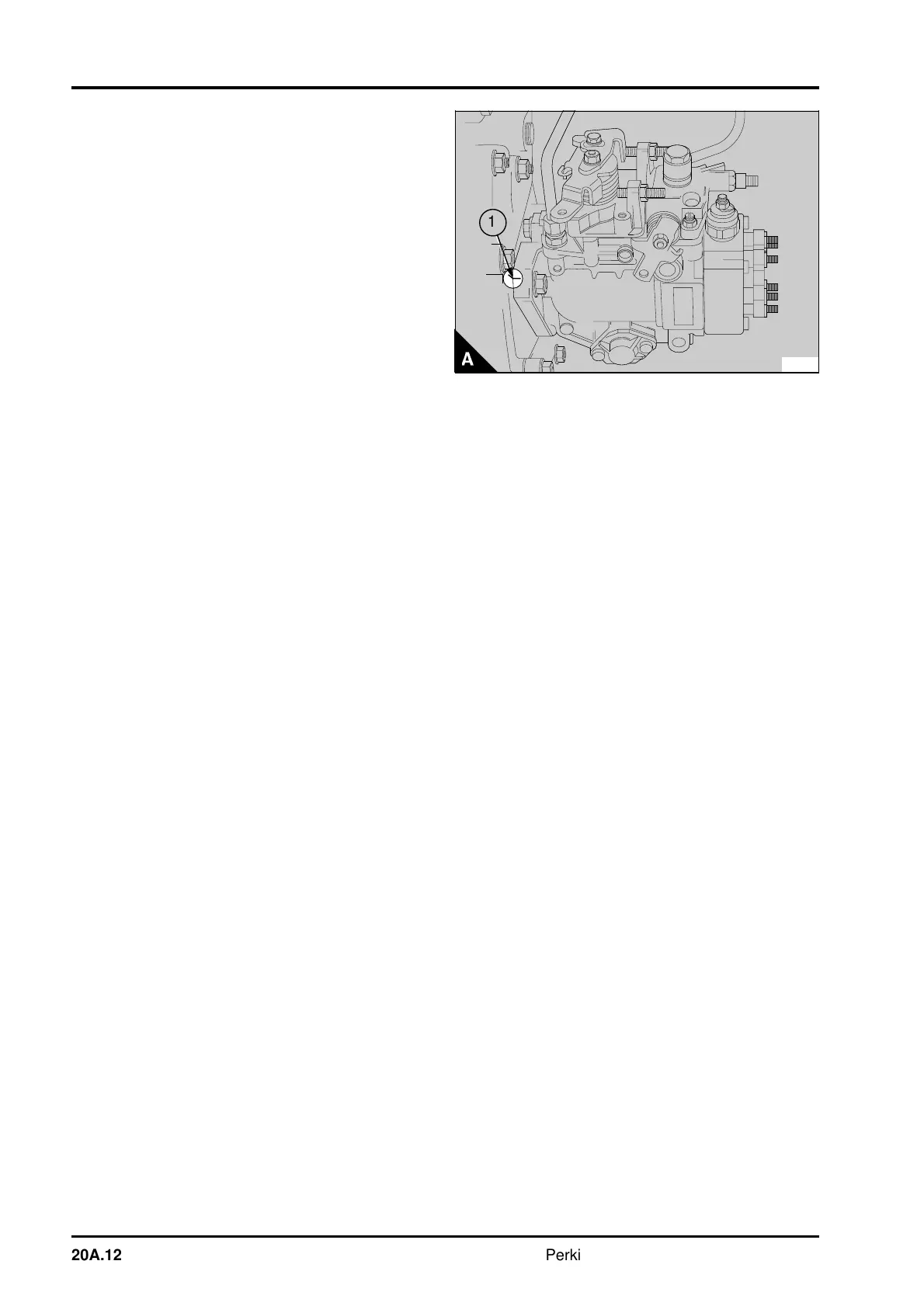

2 Align the mark on the flange of the fuel pump

with the mark on the rear face of the timing case

(A1). Fit the flange nuts of the fuel pump and the

setscrew and nut of the support bracket. Ensure

that force is not applied to the fuel pump when the

support bracket is fitted.

3 Fit the spring washer and nut to the drive shaft of

the fuel pump and tighten the nut to 80 Nm

(59 lbf ft) 8,2 kgf m. Fit the gear cover to the cover

of the timing case. Fit a new joint, if necessary.

4 Fit all the pipes, connect the stop control and the

control rod of the fuel injection pump. Ensure that a

spanner is used to prevent movement of the pump

outlets when the high-pressure pipes are fitted.

5Eliminate air from the fuel system, operation

20A-08.

6 Operate the engine and check for leakage. With

the engine at the normal temperature of operation,

check that the idle speed is correct, operation

20A-07.

7 If a new fuel injection pump has been fitted,

check the maximum no load speed, operation

20A-07.

PA255

a

a

1

20A.12 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...