FUEL SYSTEM 20B

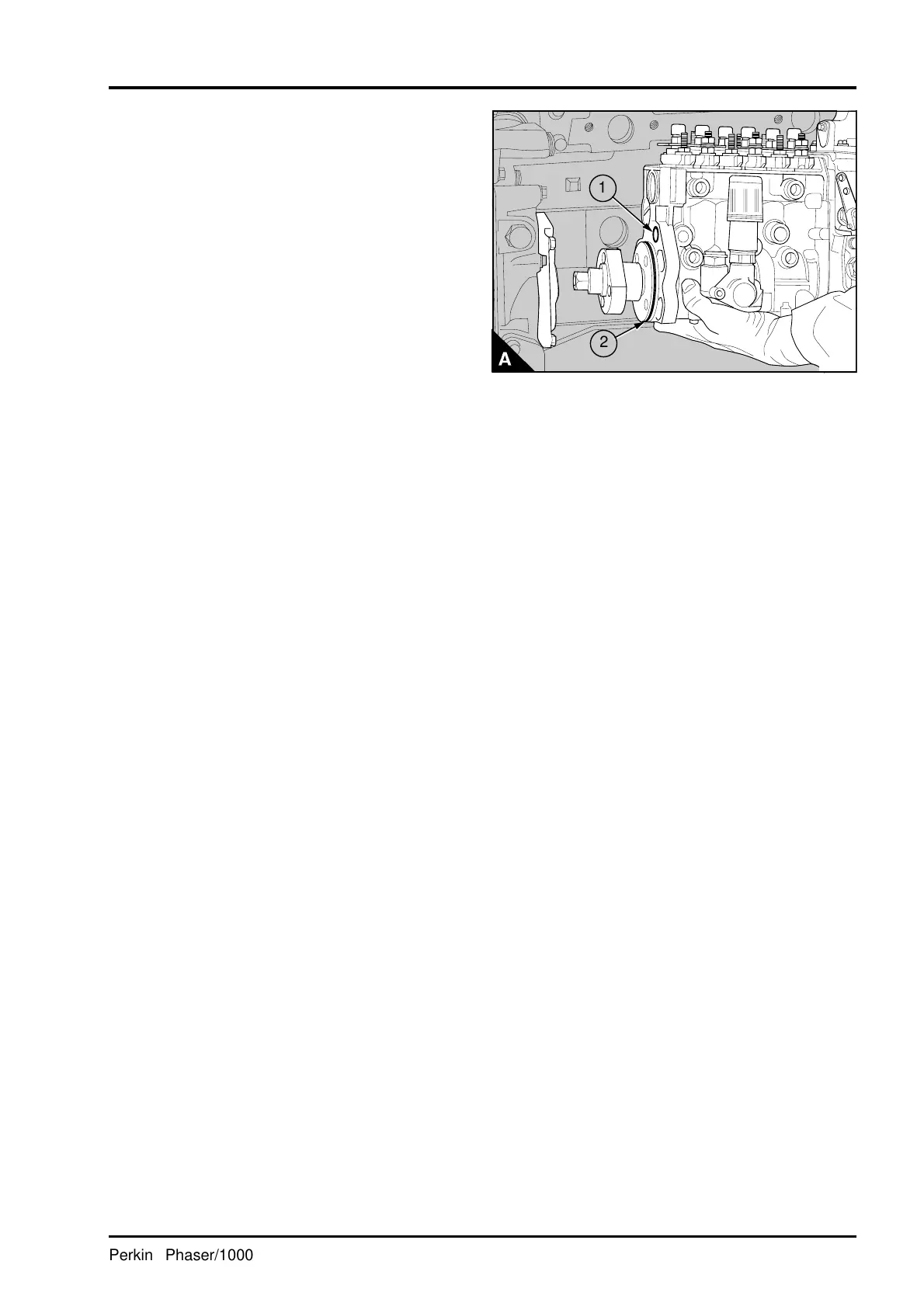

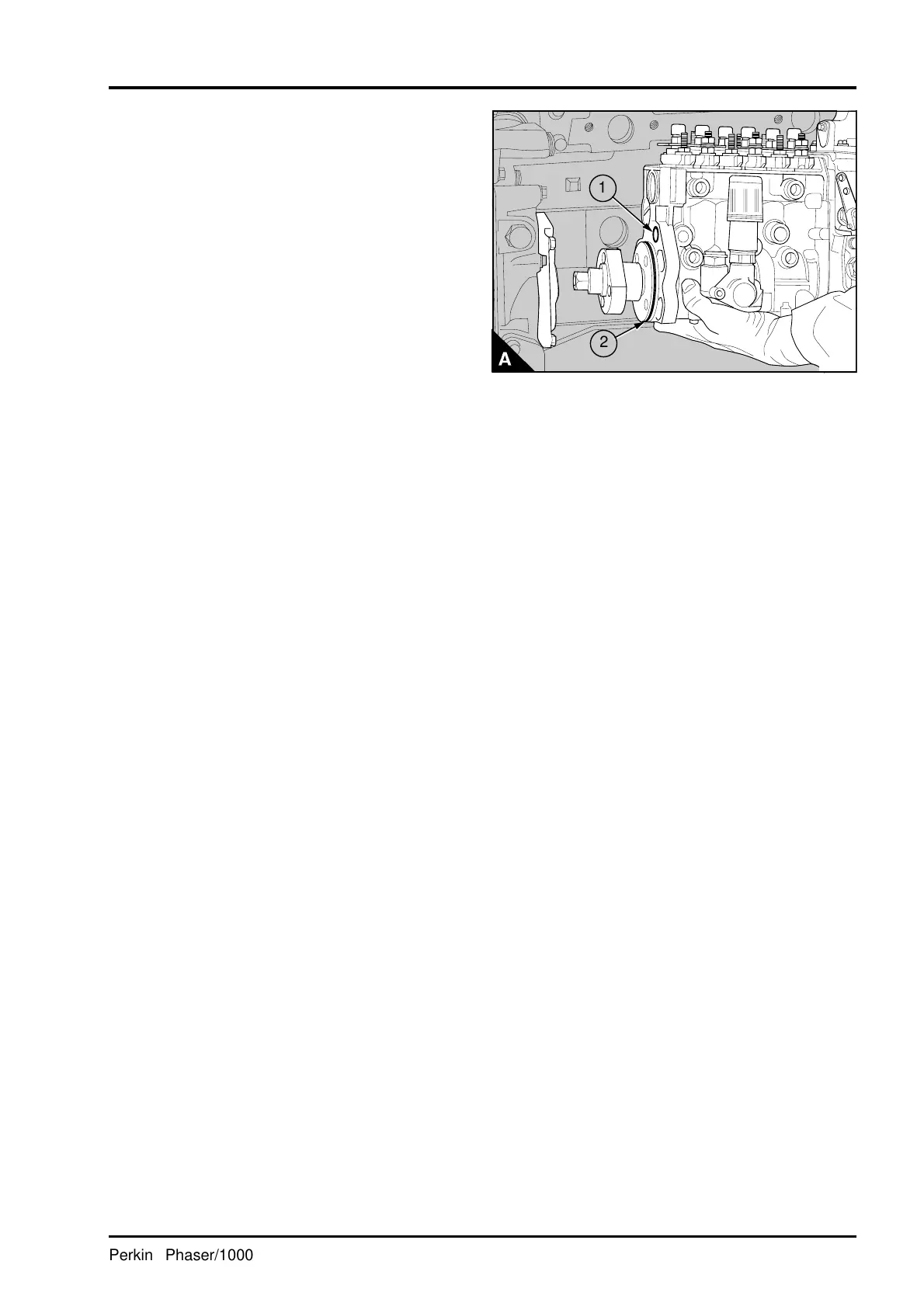

4 Lightly lubricate the "O" ring (A2) on the flange

of the pump with clean lubricating oil. Also ensure

that the small "O" ring (A1) on the flat front face of

the pump is in place.

Note: The small "O" ring was only used on early

engines. On these engines the oil supply to the

pump was connected to the adaptor plate on the

timing case. Later engines have the oil supply

connected to the side of the fuel pump and the

small "O" ring is removed.

5 Fit the fuel pump to the adaptor plate on the

timing case, ensure that the "O" ring on the flange

of the pump is not damaged. Fit the setscrews of

the fuel pump. Ensure that the fasteners are in the

centre of the slots in the pump flange and tighten

the fasteners.

6 Four cylinder engines: Fit the spacer between

the two pump support brackets, put the bolt in

position and loosely fit the nut. Adjust the brackets

to ensure that there is no tension on the fuel pump.

Tighten the setscrews that retain the bracket to the

cylinder block. Support the fuel pump and tighten

the nut and bolt.

Six cylinder engines: Loosely fit the setscrew that

holds the two brackets. Tighten the setscrews that

retain the bracket to the cylinder block. Support the

pump and tighten the setscrew that holds the two

brackets, ensure that there is no tension on the fuel

pump.

7 Put the drive gear in position on the hub of the

fuel pump, operation 15A-04. Ensure that the gear

is fully in position on the hub. Fit the plate to the

gear, ensure that the plate does not fall into the

timing case. Fit the cap screws and tighten them

enough to allow movement between the hub and

the gear.

PA196

1

a

a

2

Perkins Phaser/1000 Series, April 1995 20B.09

Loading...

Loading...