20E FUEL SYSTEM

To adjust - Stanadyne pump20E-07

To adjust

1 Operate the engine until it reaches its normal

temperature of operation and check the idle speed.

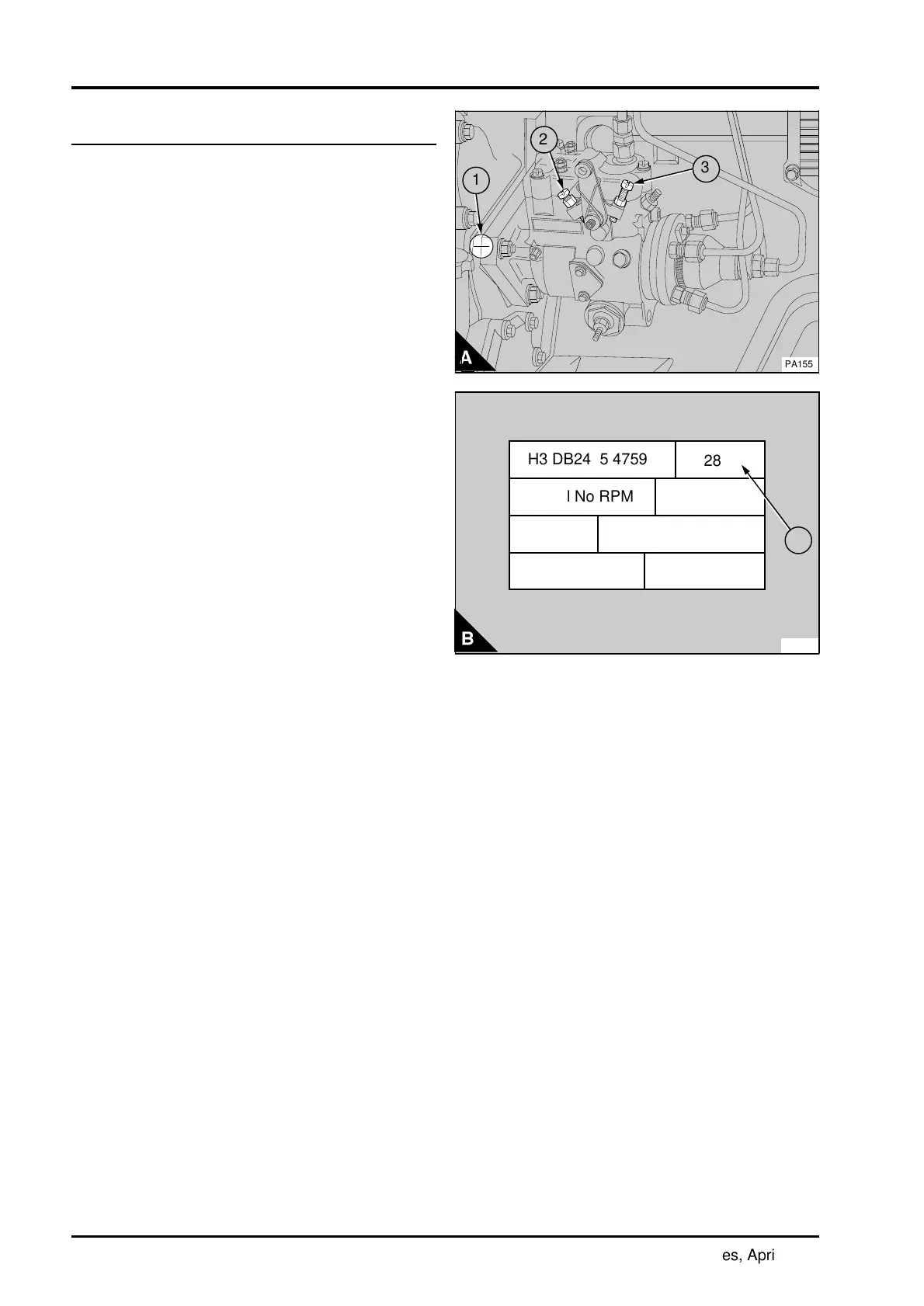

If necessary, adjustment can be made by the

adjustment screw (A2). Release the lock nut and

rotate the adjustment screw clockwise to increase

the speed or counter-clockwise to decrease the

speed. When the speed is correct, tighten the lock

nut. The correct speed will normally be given in the

manufacturer's handbook for the application. If it is

not given, apply to your nearest Perkins distributor

or to Technical Services Department, Perkins

International Ltd, Peterborough, England.

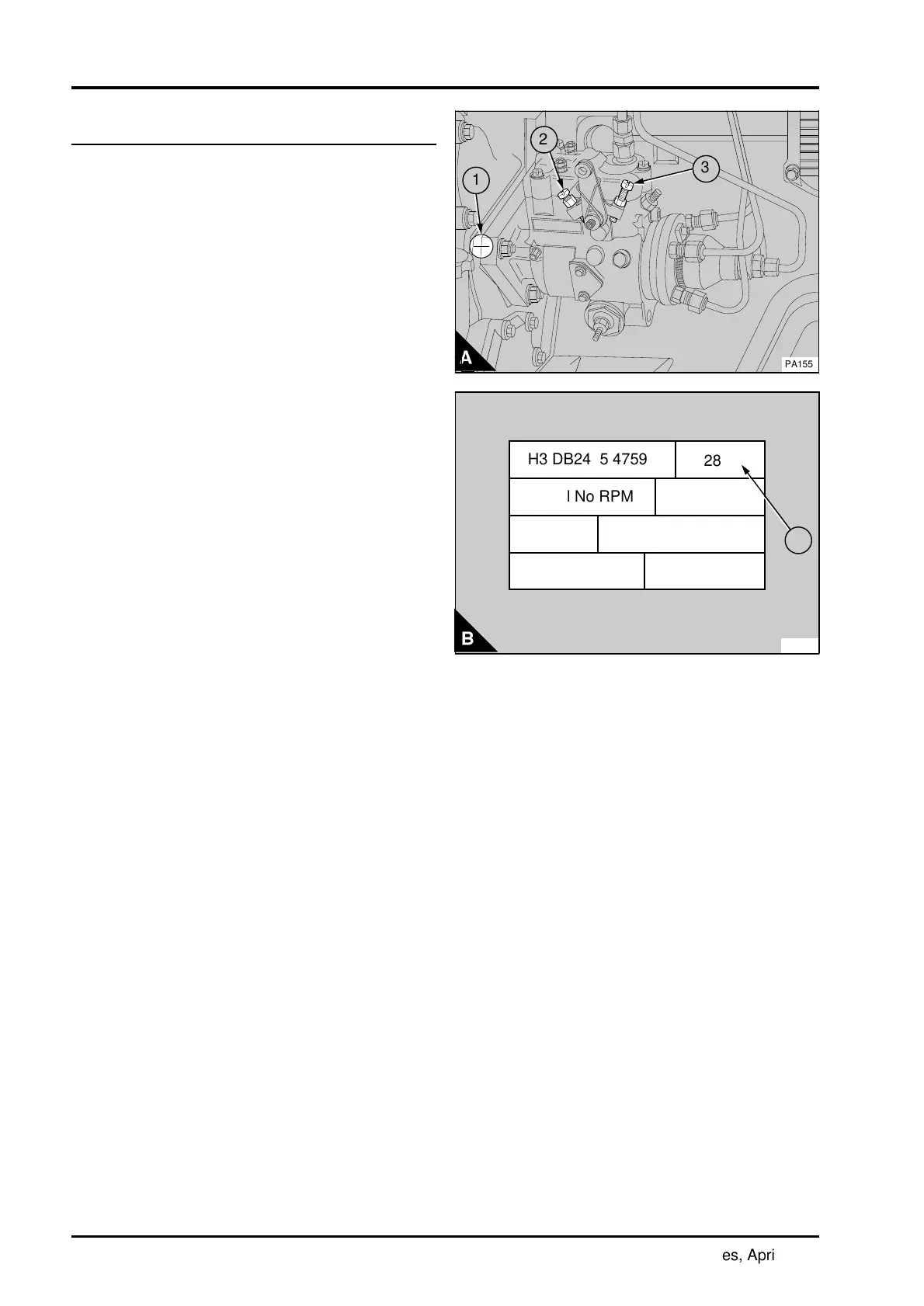

Caution: The setting for the maximum no load

speed can change for different applications. Always

check the fuel injection pump data plate (B) fitted to

a specific engine, before any adjustment to the

maximum no load speed.

2 With the engine at its normal temperature of

operation, check the maximum no load speed on

the fuel pump data plate. An example is given at

(B1); if necessary, this speed can be adjusted by

the adjustment screw (A3). Release the lock nut

and rotate the adjustment screw counter-clockwise

to increase the speed, or clockwise to decrease,

the speed. When the speed is correct, tighten the

lock nut and seal the screw. The person who fits

the pump must ensure that the adjustment screw is

suitably sealed against interference after it has

been set initially. The adjustment screw on original

fuel pumps is set and sealed by the manufacturer.

The setting must not be changed as this could

affect the engine warranty.

a

a

a

3

2

PA155

1

H3 DB2435 4759

2820

Model No RPM

Ser N

o

Mfg N

o

2643U001 AL

7585429

PA153

1

20E.04 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...