14 CRANKSHAFT ASSEMBLY

8 Fit the setscrews and the washers to the main

bearing caps and tighten the setscrews gradually

and evenly to 265 Nm (196 lbf ft) 27,0 kgf m for six

cylinder engines and 250 Nm (185 lb ft) 26,0 kgf m

for four cylinder engines.

Note: Washers are not fitted between the

setscrews and the bearing caps on the latest

engines.

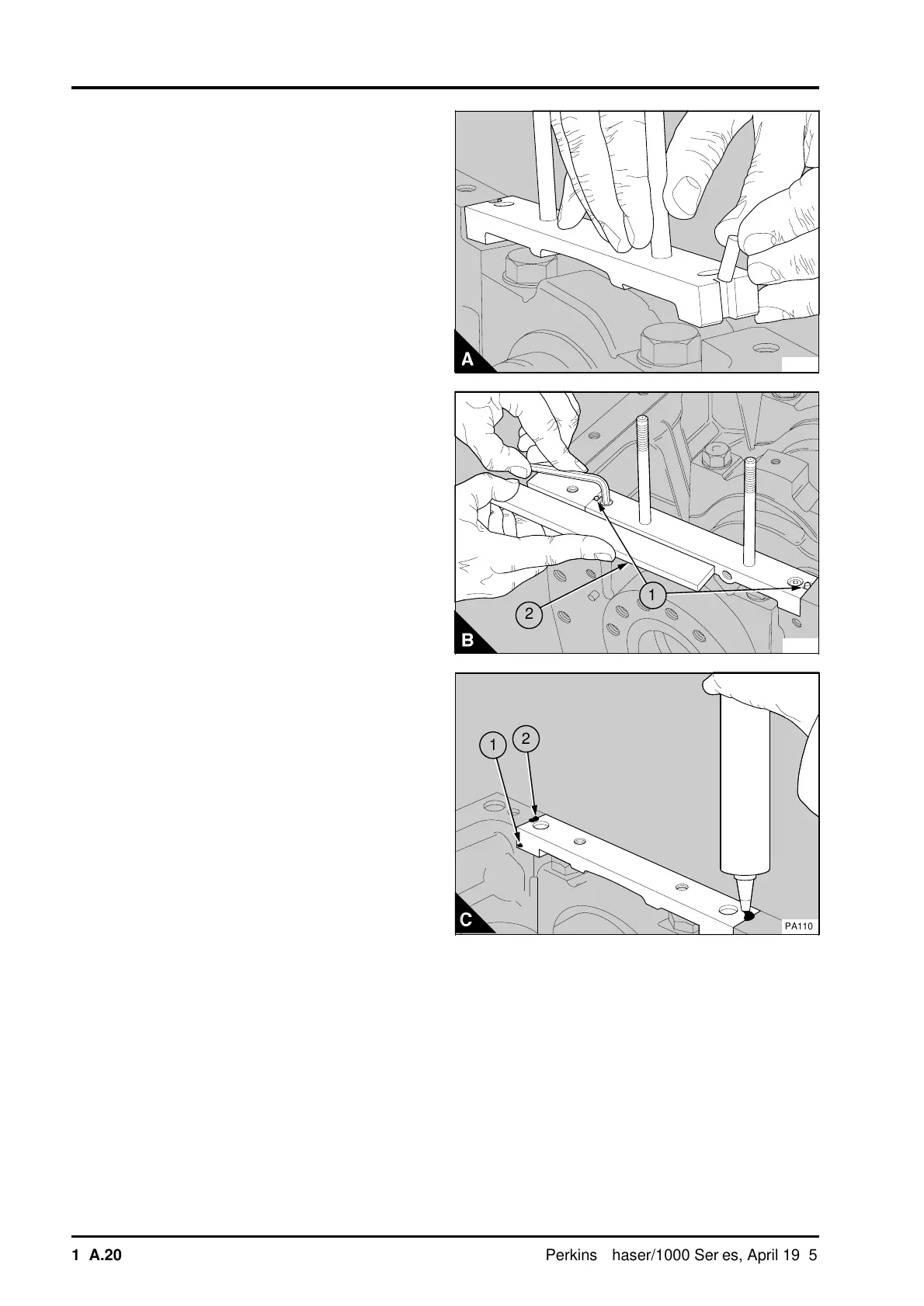

9 For early engines fitted with rubber seals: Clean

the bridge piece and the location areas for the

bridge piece in the cylinder block. Apply a narrow

strip of POWERPART silicone rubber sealant in the

corners and around the thread holes of the bridge

piece seat in the cylinder block. Fit the bridge piece

and the two rubber seals (A). The rubber seals will

be a little higher than the bridge piece when they

are fitted correctly. Use a straight edge (B2) to

ensure that the bridge piece is in line with the rear

face of the cylinder block. Tighten the bridge piece

cap screws (B1) to 16 Nm (12 lbf ft) 1,6 kgf m.

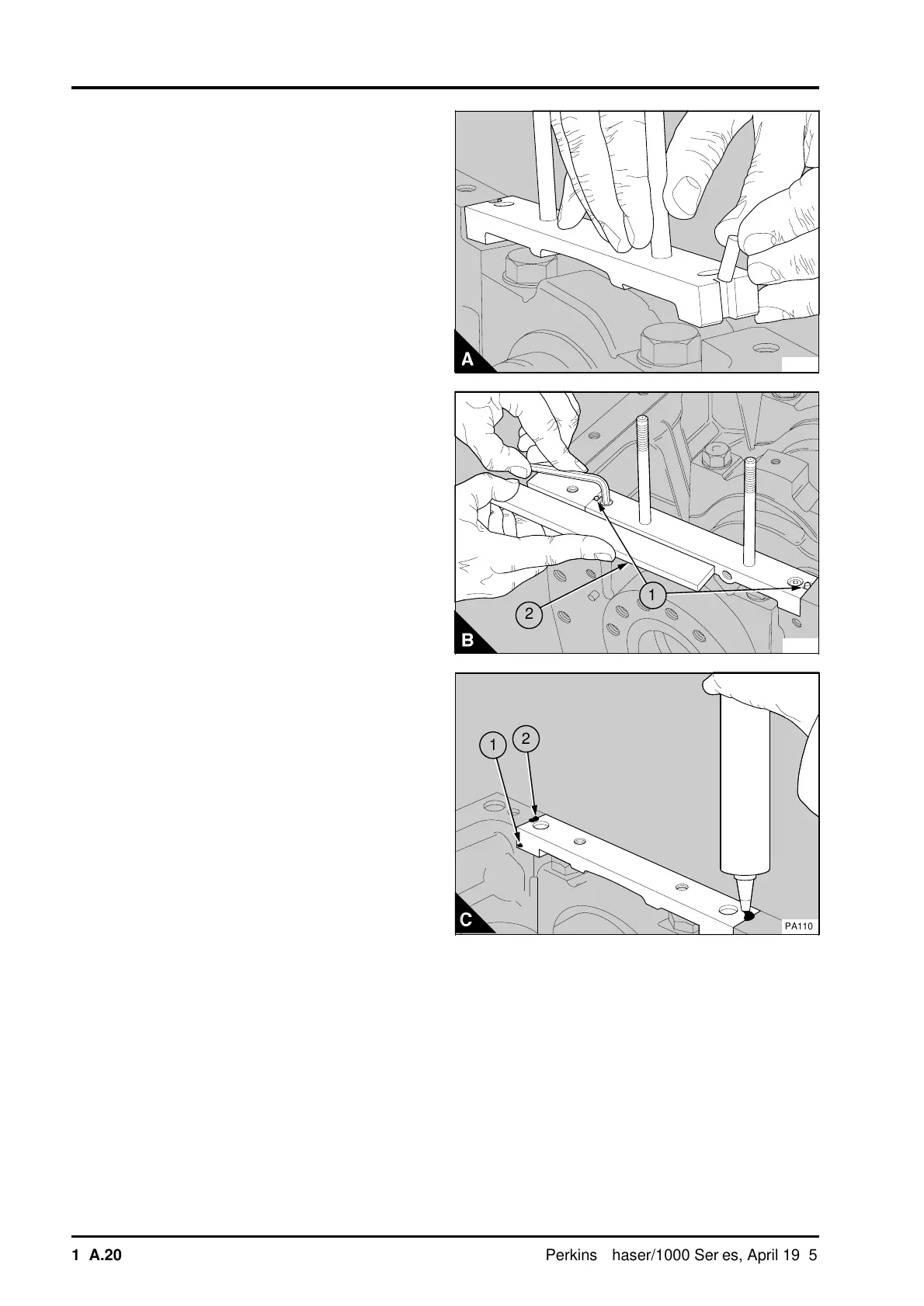

For later engines fitted with POWERPART liquid

gasket: A bridge piece has been introduced which

uses POWERPART liquid gasket instead of the

rubber seal in the groove at each end of the bridge

piece. The groove at each end of the new bridge

piece is cast and is off-centre. The procedure to fit

the new bridge piece is the same as for the earlier

bridge piece, except for the instructions given

below. Apply a 1/8 in (3.0 mm) bead of

POWERPART liquid gasket along the corner in the

top of the recess in the cylinder block for the bridge

piece.

When the bridge piece is in position and the cap

screws have been tightened, inject POWERPART

liquid gasket into the groove (C2) at each end of

the bridge piece. Continue to inject sealant until the

groove is completely full and the sealant leaves the

lower groove (C1) at the front and rear of the bridge

piece.

It may be necessary to stop the sealant at one side

of the lower groove in order to ensure it will flow

from the opposite side of the groove.

PA108

PA109

2

a

a

1

1

2

PA110

14A.20 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...