14 CRANKSHAFT ASSEMBLY

Balancer unit

To remove and to fit14A-10

To remove

1 Drain the lubricating oil from the sump and

remove the sump, operation 19A-03.

Warning! The weight of the unit is approximately

25 kg (55 lb).

2 Provide a support for the balancer unit before

release of the setscrews from the engine.

3 Release the setscrews and lower carefully the

balancer unit. Make a note of the positions of the

setscrews of different lengths.

To fit

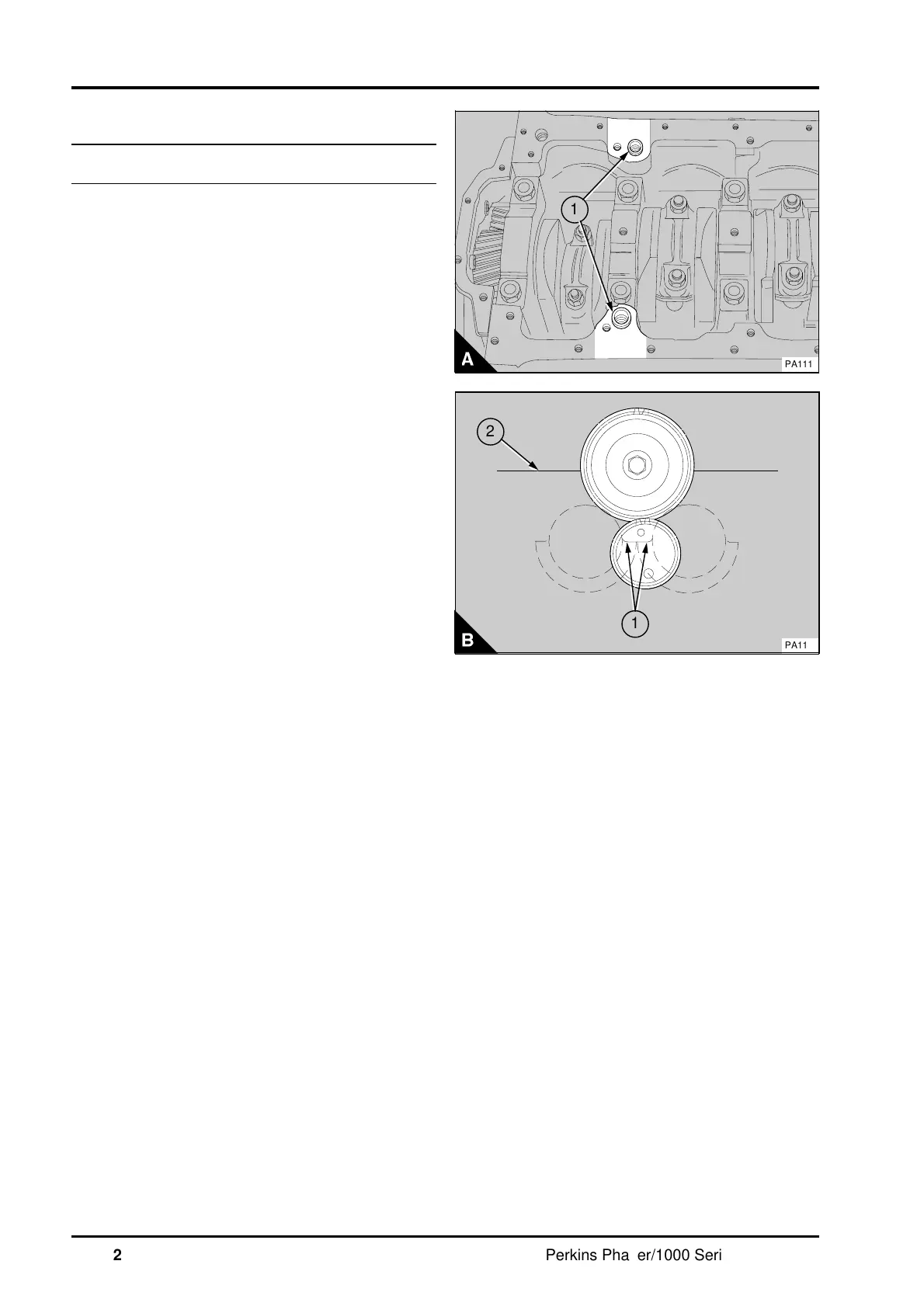

1 Ensure that the contact faces of the cylinder

block and of the balancer unit are clean and that

the two thimbles (A1) are fitted correctly to the

cylinder block.

2 Set the piston of number 1 cylinder to TDC,

operation 17A-01.

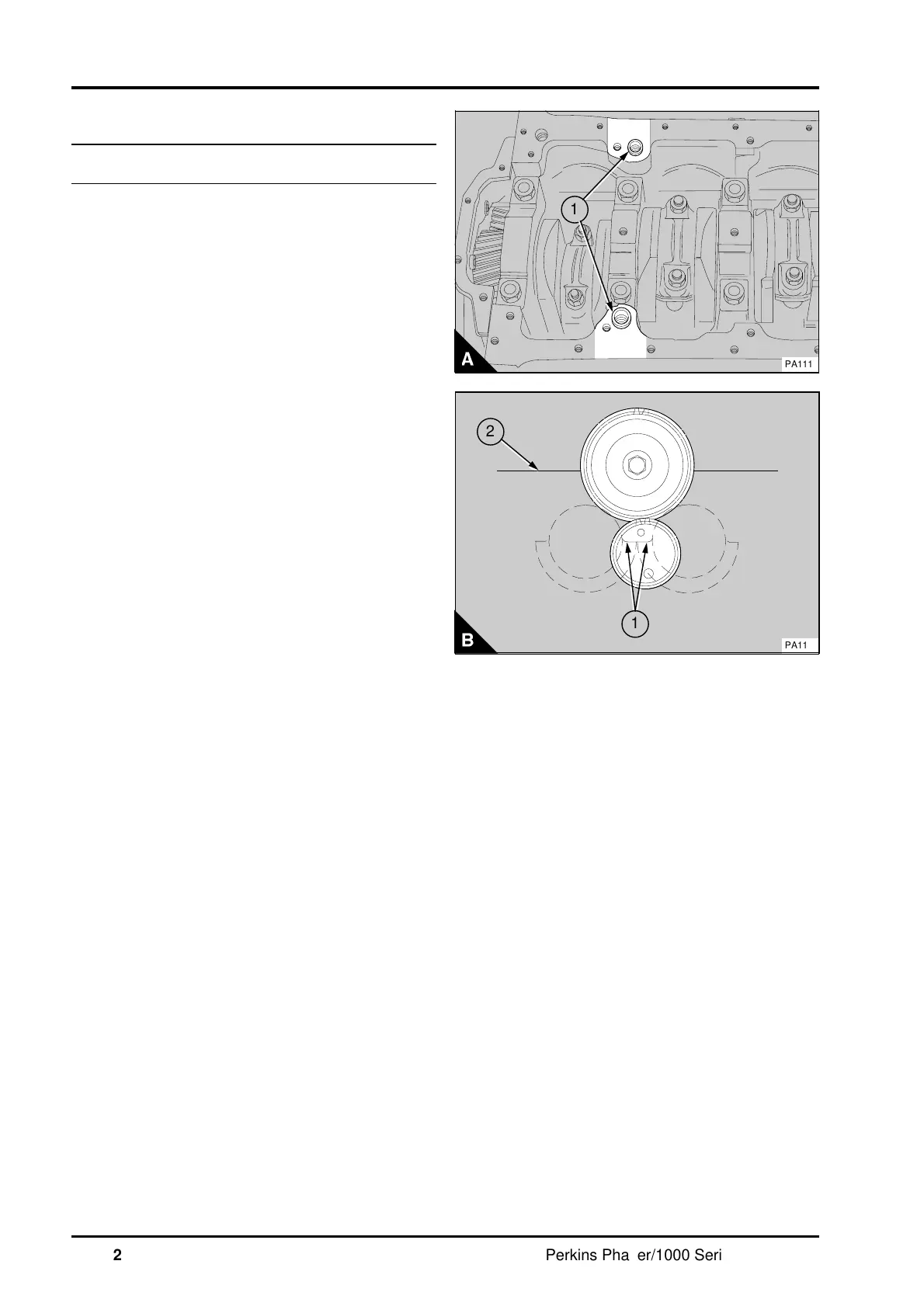

3 Before the balancer unit is fitted, ensure that the

flat faces of the balance weights are level with each

other (B1) and the weights hang down away from

the cylinder block (B2). The timing of the balance

weights to the drive shaft is correct when the large

hole and small hole in the front of the drive shaft

gear are in the positions shown in the illustration

(B).

Note: If the gear position shown in (B) cannot be

obtained, then the balancer must be partially

dismantled and the timing corrected (14A.26/A).

4 Fit the balancer unit to the cylinder block with the

correct screws in the centre positions of the

balancer frame. Ensure, when the idler and

crankshaft gears are in mesh, that the flat faces of

the balance weight are level with each other and

that they are towards the cylinder block. Check that

the balancer unit is fitted correctly on the thimbles

and fit the remainder of the setscrews in their

correct position. Tighten the setscrews to 54 Nm

(40 lbf ft) 5,5 kgf m.

5 Rotate the crankshaft through two turns to

ensure that it is free to rotate.

6Fit the lubricating oil sump, operation 19A-03 and

fill the sump to the correct level with an approved

oil.

a

a

1

PA111

a

a

1

a

a

2

PA112

14A.22 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...