Section 4.2

Machine Adjustments

400-088-120-02 4.2-3 Rev Date: 10/2016

4.2.2 Table Adjustments

4.2.2.1 Tie Rod Adjustment

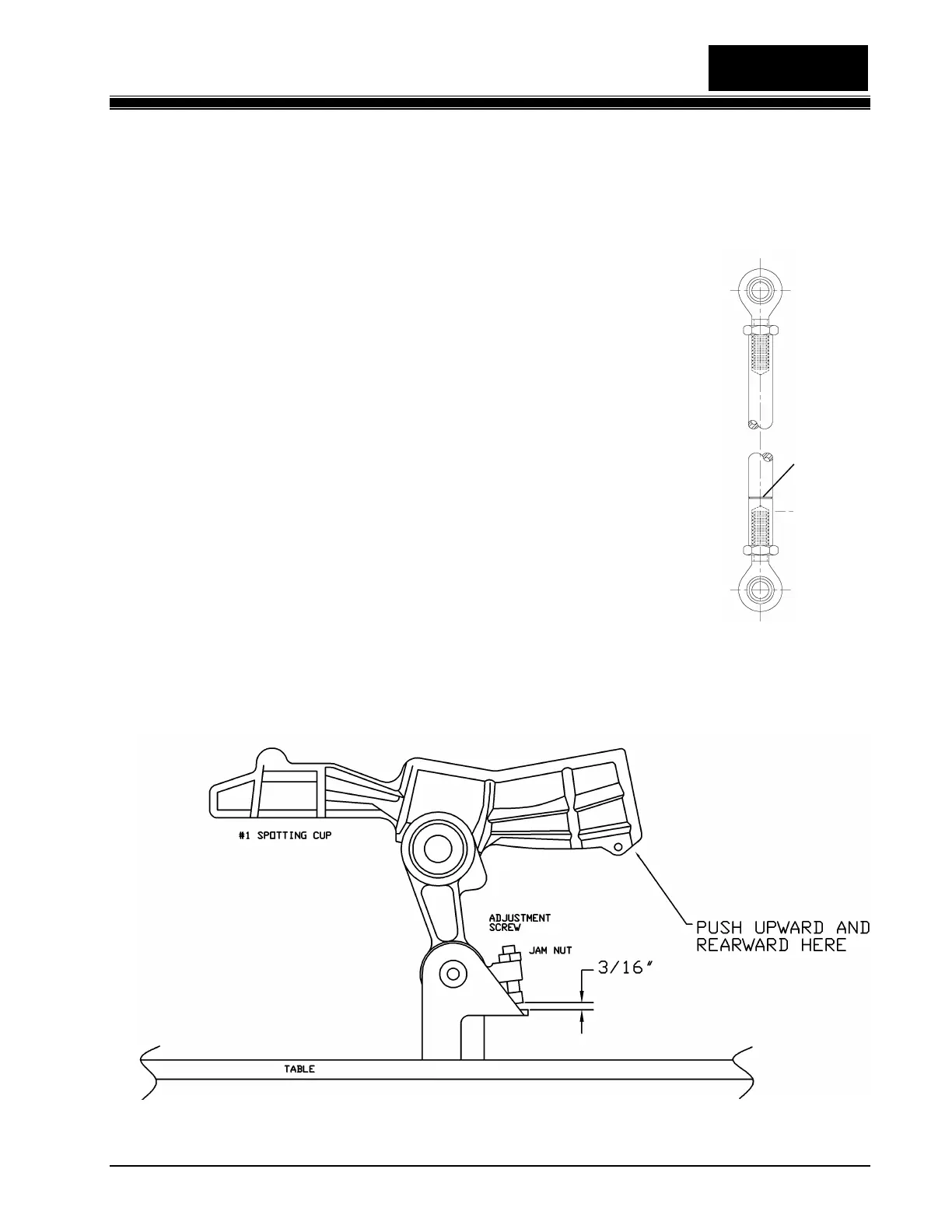

Throughout this section, references to adjusting the various tie rods are

made. A tie rod (Figure 4.2-3) is a device that consists of two threaded

sections and a center section into which the threaded sections fit. On

most tie rods, one threaded section has standard right-hand threads, and

the other threaded section has left-hand threads. Turning the center

section increases or decreases the tie rod’s overall length. The end with

the left-hand threads can be identified by a line scribed around the

circumference of the center section near the end. It is helpful to know

which end is left threaded because there is a jam nut on each of the

threaded sections, and the left-threaded nut must be turned opposite the

normal direction to loosen. A few tie rods have right-hand threads on

both ends to prevent the tie rod from going out of adjustment during

operation, and at least one end must be disconnected for it to be

adjusted. Loosen the jam nuts before making any tie rod adjustments,

and tighten them after adjustments have been made.

The following Table adjustments are presented in the order in which they

should be performed for optimal results.

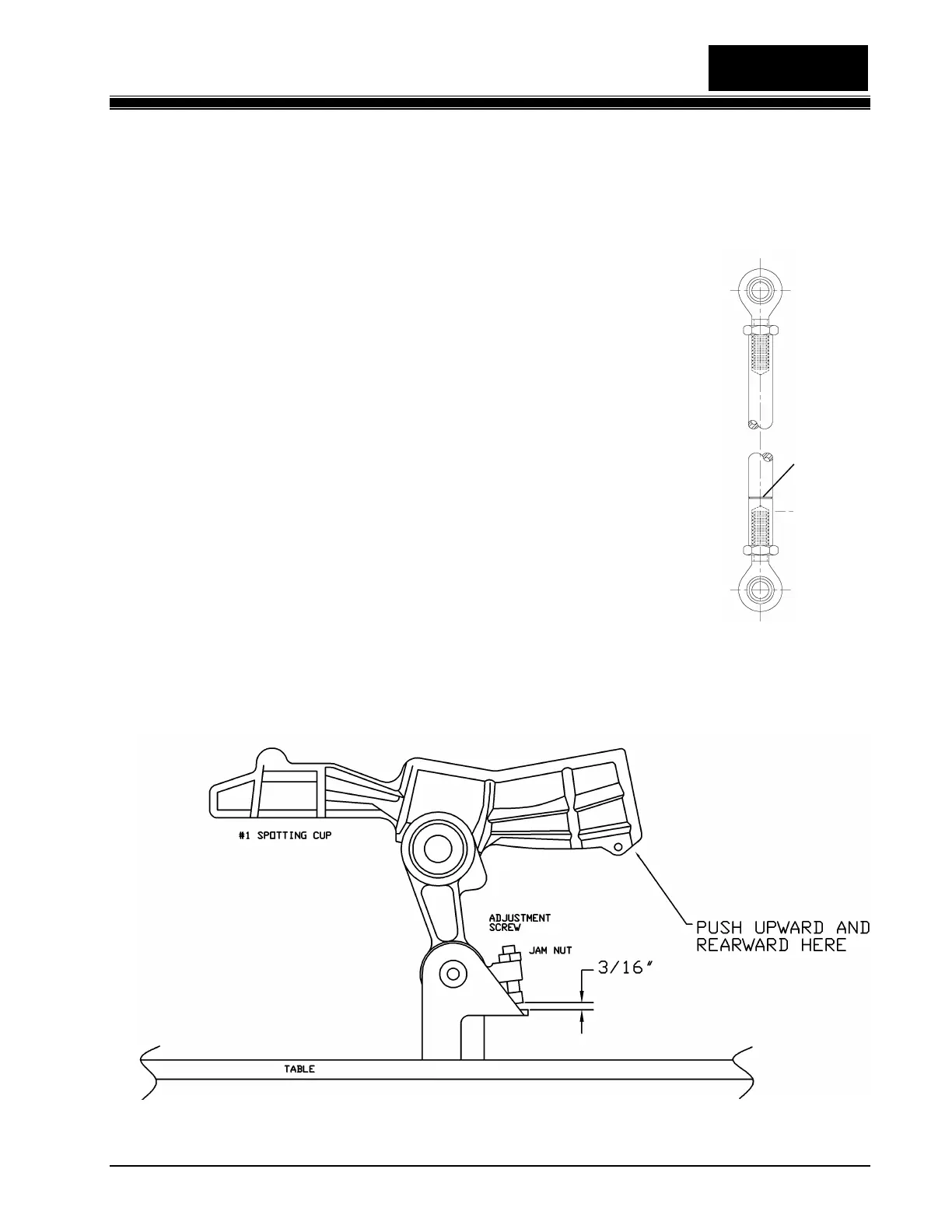

4.2.2.2 Table Leg Screw Adjustment

Figure 4.2-4

Line indicates

end of tie rod

with left-hand

threads.

Loading...

Loading...