B-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

112 of 147

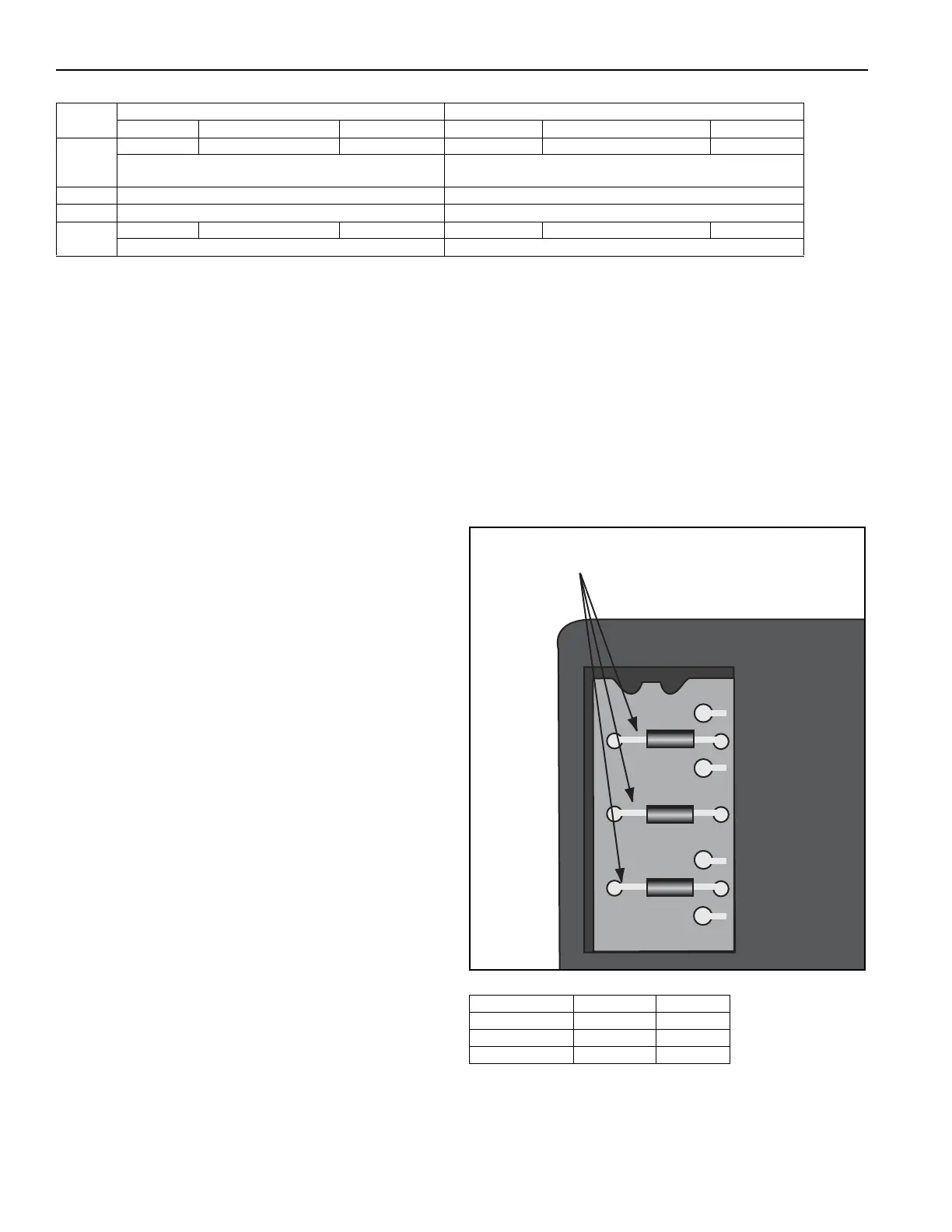

Table 18: Factory Preset Schedule on TH8110 Thermostat

18.2.4 BMS-Ready Control Option

The BMS-ready option provides inputs to receive

control signals from a customer determined control

system. Each BMS input is capable of receiving a

4-20mA or 0 - 10VDC from the control system. On all

air handlers, the burner modulation will be controlled

by the control system. For AM/VAV style air handlers,

the control system can also control the modulating

damper.

On DDC/BMS-ready systems, no temperature control

amplifier is installed. Discharge temperature

monitoring and modulation valve adjustment are

completed by the customer supplied control system.

For optimum efficiency, Rapid Engineering LLC

suggests to limit the discharge temperature to 160 °F.

18.3 Basic Air Handler Sequence of Operation

While the control transformer is energized, the

secondary side supplies 115 VAC to the control

circuit. When the fan switch is in the "on" position, the

M1 motor starter is energized and starts the blower

motor. The M1 motor starter auxiliary contact

supplies voltage to the burner switch and "Fan On"

light. When the burner switch is in the "on"/"winter"

position, po

wer is supplied to the flame control

module and the burner control circuit. The burner

control circuit includes the high temperature limit

switch and the low and high airflow pressure

switches. Once the burner control circuit is satisfied,

then the flame control module will execute the burner

ignition sequence. Once the pilot flame is ignited and

sensed by the UV scanner, the flame control module

will open the safety shutoff valve to ignite the main

flame. When the safety shutoff is opened, 115 VAC is

applied to the "Burner On" light and T3 transformer,

the secondary side supplies 24 VAC to the

temperature control amplifier. The temperature

control amplifier controls the modulating valve based

on the discharge temperature monitor (and also the

room temperature monitor, in the case of a DTC

remote panel).

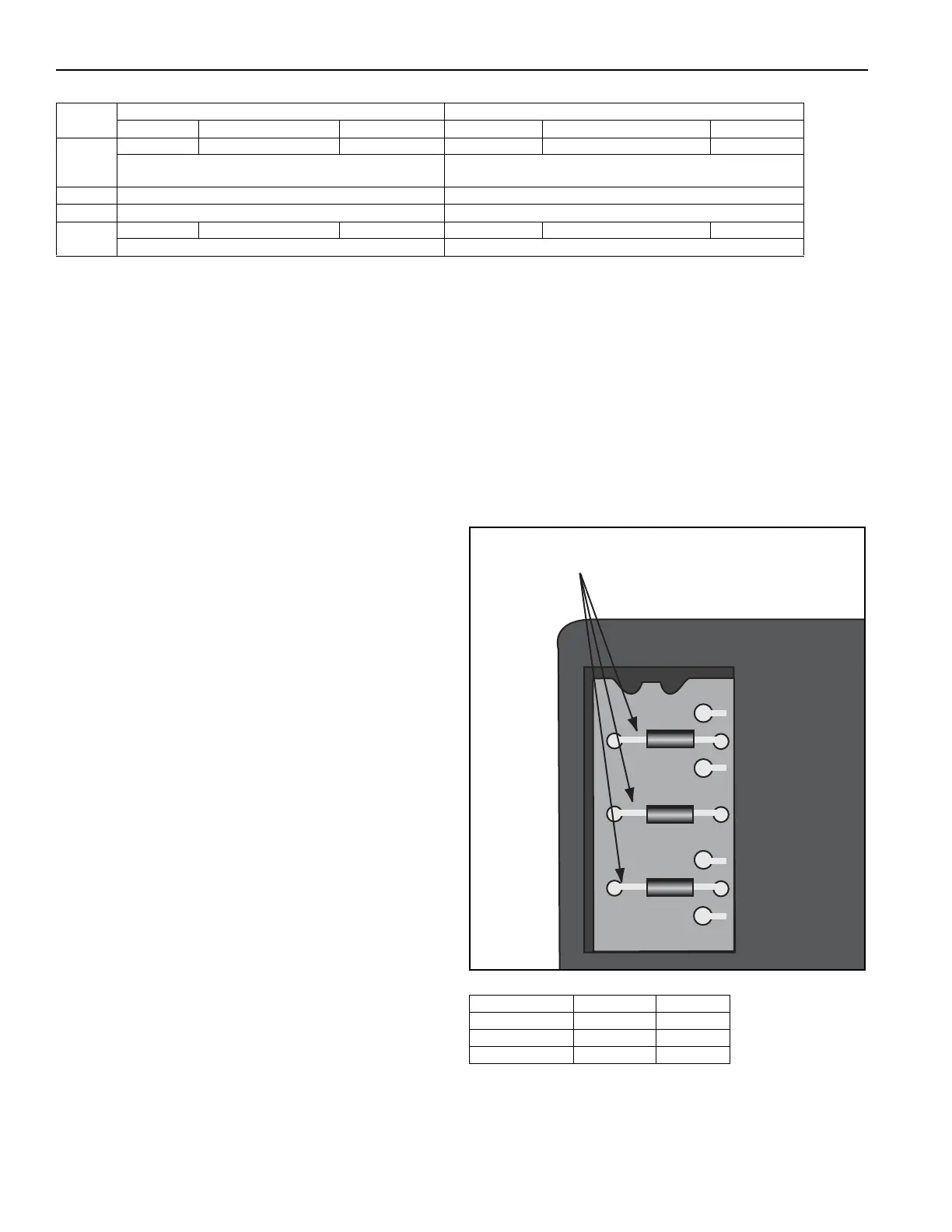

18.3.1 Flame Control

The flame control is a safety device and not

servicable. See Page 113, Figure 73 through Page

115 , Fig u re 7 5 for detailed seq

uence of operation.

The RM 7890 and RM 7897 must be configured prior

to replacement. This is done by removing certain

configuration jumpers on the upper left corner of the

flame control, located behind the blue cover. See

Page 112, Figure 72 and Page 112, Table 19.

FIGURE 72: Honeywell Safeguard Jumpers

Table 19: Site-Configuration Jumper Options

Monday - Friday Saturday - Sunday

Time Temperature Fan Setting Time Temperature Fan Setting

Wake

6:00 AM 68° F Fan On 6:00 AM 62° F Fan Auto

The air handler will run continuously.

Temperature controlled by Maxitrol stat.

The air handler will run when the thermostat calls for heat.

Leave Unused Unused

Return Unused Unused

Sleep

5:00 PM 62° F Fan Auto 5:00 PM 62° F Fan Auto

The air handler will run when the thermostat calls for heat. The air handler will run when the thermostat calls for heat.

Jumper Number 7890 7897

JR1 Intact Intact

JR2 RemoveRemove

JR3 Intact Intact

JR1

JR2

JR3

Selectable Configuration Jumpers

Loading...

Loading...