SECTION 19: START-UP PROCEDURES

117 of 147

Installation Code and Annual Inspections:

All installation and service of RAPID

®

equipment

must be performed by a contractor qualified in the

installation and service of equipment sold and

supplied by Rapid Engineering LLC and conform to

all requirements set forth in the RAPID

®

manuals and

all applicable governmental authorities pertaining to

the installation, service, labeling and operation of the

equipment.

To help facilitate optimum performance and safety,

Rapid Engineering LLC recommends that a qualified

contractor conduct, at a minimum, annual

inspections of your RAPID

®

equipment and perform

service where necessary, using only replacement

parts sold and supplied by Rapid Engineering LLC.

Check installation site to ensure all codes and

engineering specifications are correct. This section of

the manual is intended to be used as an instructional

guide to the commissioning of the direct fired air

handler. Fill out the start up sheet located at the back

of the manual as each step of the procedure is

performed. This procedure must be completed by the

commissioning contractor and returned to Rapid

Engineering LLC. If the document is not returned, the

manufacturing date will be used as the warranty start

date.

All components have been checked at initial factory

startup. During transit components may have

loosened/shifted, check all wiring before initial

startup.

19.1 Installation of Recirculating Air Handler

Every direct-fired air handler which recirculates room

air (i.e., AM and FR styles) must utilize either a

control system which limits temperature rise in

proportion to the amount of ou

tdoor air, or a room

carbon dioxide sensor, installed per the

manufacturer’s recommendations. The normally-

closed contacts of this sensor must be wired in as

per the CO

2

interlock diagram, maintaining the room

concentration of CO

2

below 5,000 ppm. Select the

CO

2

interlock diagram based on air handler

configuration and model. See Page 97, Figure 56

through Page 97, Figure 58.

With the AM and VAV package, a temperature rise

limiting resistor comes prewired. See Page 90,

Figure 48 through Page 96, Figure 55. When the air

handler goes into full recirculation, the resistor is

activated, lowering the maximum temperature rise to

comply with government standards. For the FR

package, the gas valve is preset to the proper

temperature rise. See Page 121, Table 24.

19.2 Mechanical

This piece of equipment requires at least 4 CFM

(6.8m

3

/h) of outside air per 1,000 Btu/h (0.293 kW).

Before installation, check that the local distribution

condition, nature of gas and pressure, and the

current state of adjustment of the equipment are

compatible.

If filters are not installed (via inlet hood or filter

section), an air strainer must be installed on the inlet

of the air handler with openings less than or equal to

5/8" (16 mm) in diameter.

Air inlets must be installed with the lowest edge 19"

(500 mm) above any surface. This applies to roof

curbs, upright stands and suspended air handlers.

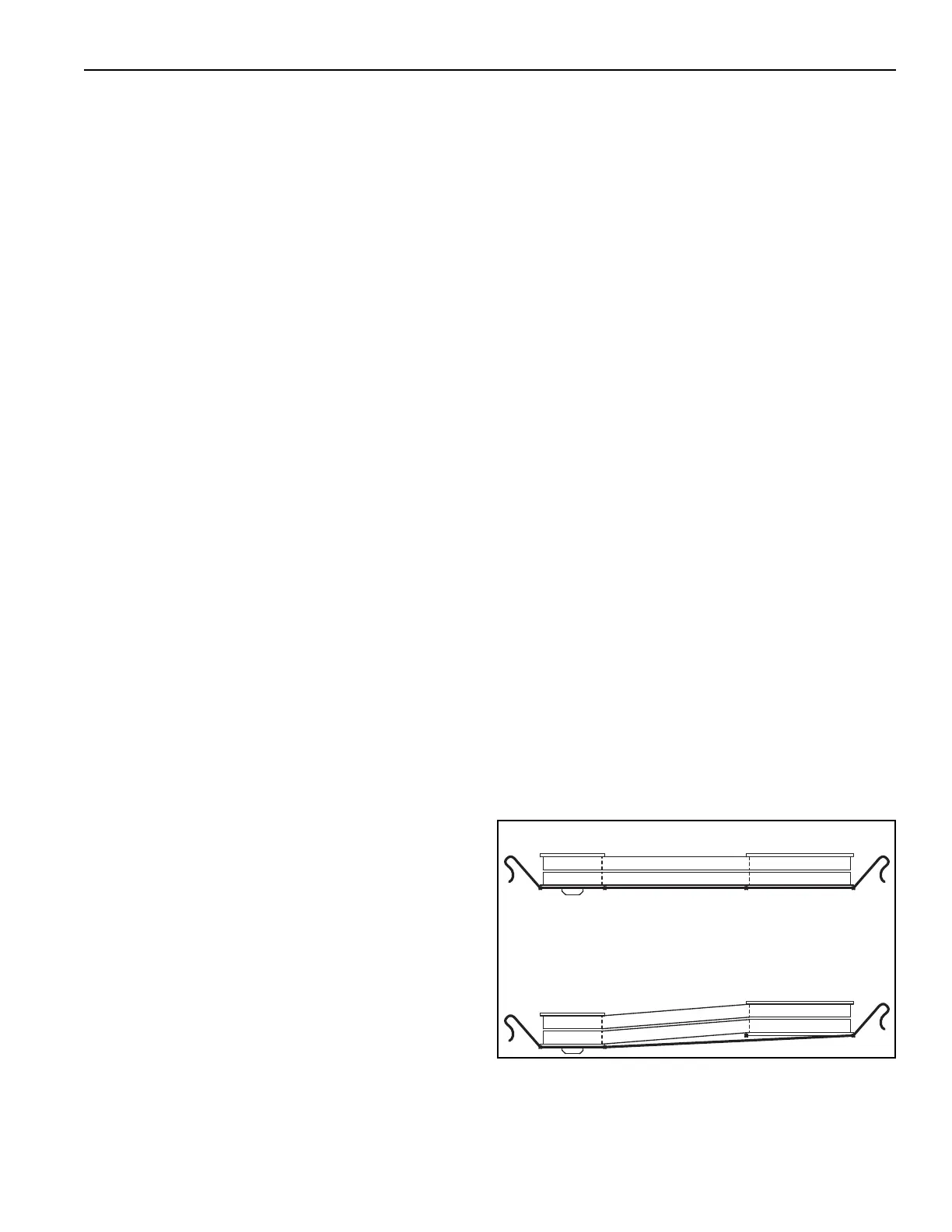

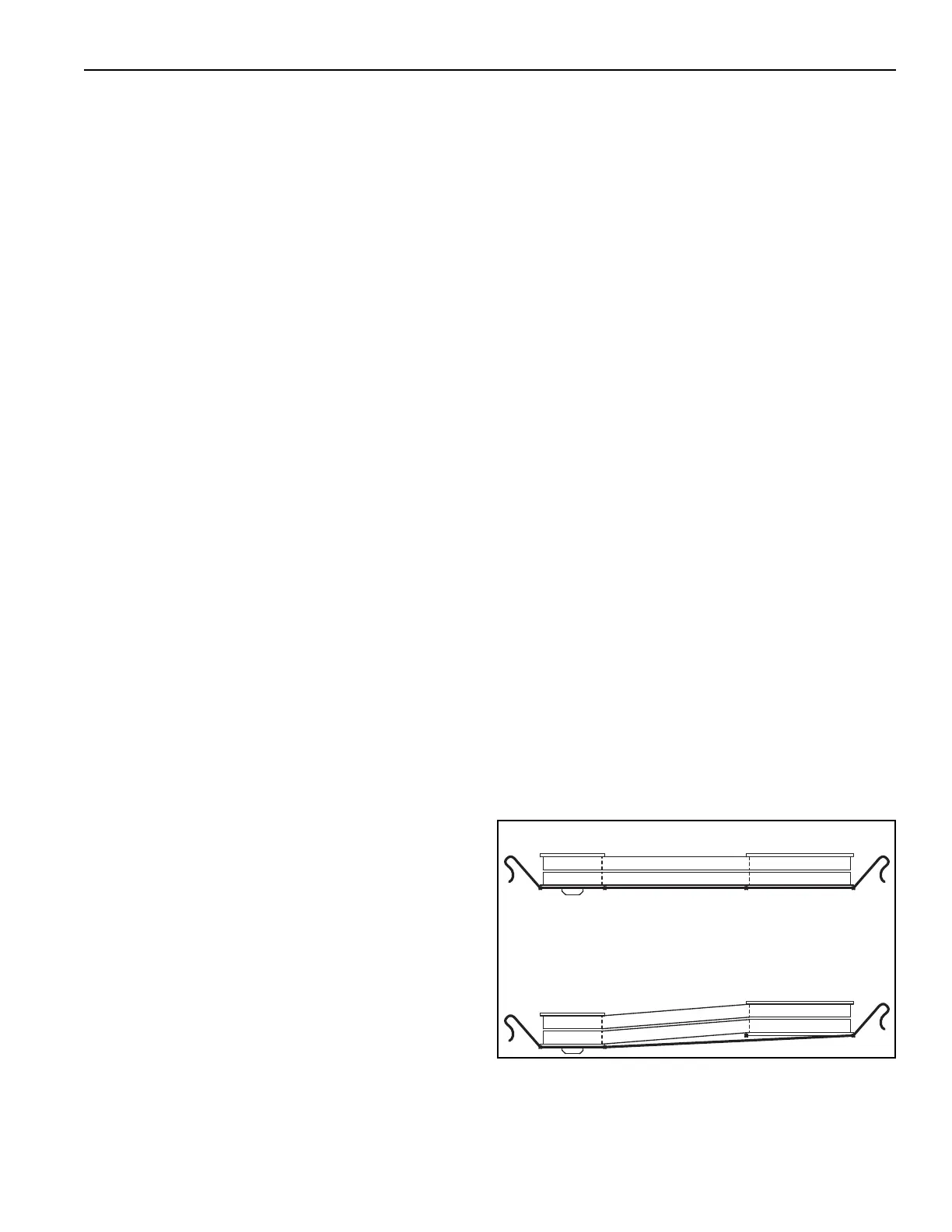

19.2.1 Sheave Alignment

Sheaves are factory aligned. On all air handlers,

check sheave alignment as follows.

1. Attach a string to the vertical surface next to

the blower shaft bearing. (See Page 117, Figure

76)

2. Wrap the string around the blower sheave and

across both sheave surfaces as shown.

3. Adjust until all four contact points (triangle)

touch the sheave s

urfaces. "IN" or "OUT"

adjustment of the motor sheave and/or motor

adjustment may be required.

4. Pull the string away from the motor sheave and

then move it slowly back towards the sheave,

making sure the string remains straight while

touching all contact points.

5. Remove string before turning air handler on.

FIGURE 76: Sheave Alignment

Correct Alignment

Incorrect Alignment

Loading...

Loading...