B-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

74 of 147

SECTION 16: GAS PIPING

16.1 Gas Manifolds

All gas piping to the air handler must comply with:

United States: Refer to NFPA 54/ANSI Z223.1 - latest

revision, National Fuel Gas Code.

Canada: Refer to CSA B149.1 - latest revision,

Natural Gas and Propane Installation Code.

The air handlers are available with three gas manifold

options.

• American National Standards Institute (ANSI)

compliant manifold: (

See Page 75, Figure 32

for

2005.

See Page 75, Figure 33

for 2010 - 2030.

•Factory Mutual (FM)-compliant manifold:

(

See Page 75, Figure 32

for 2005.

See Page 76,

Figure 34

for 2010 - 2030.

• XL compliant manifold: (

See Page 75, Figure 32

for 2005.

See Page 76, Figure 35

for 2010 - 2030.

16.2 Gas Piping and Pressures

The air handler is equipped with a gas manifold

suitable for connection to supply pressure of up to:

•14 in wc maximum (34.9 mbar) (2005 - 2030 with

ANSI-compliant manifold.)

•5 p.s.i. maximum (2005 - 2030 with FM or XL

compliant manifold).

When gas supply exceeds the above-listed maximum

gas pressures, an additional high pressure gas

regulator will be required to assure that the correct

gas pressure is supplied to the regulator. Pressure

should be measured between the high pressure gas

regulator and safety shut off valve. Minimum gas

pressure as indicated on data plate must be

measured with the burner operating in high fire.

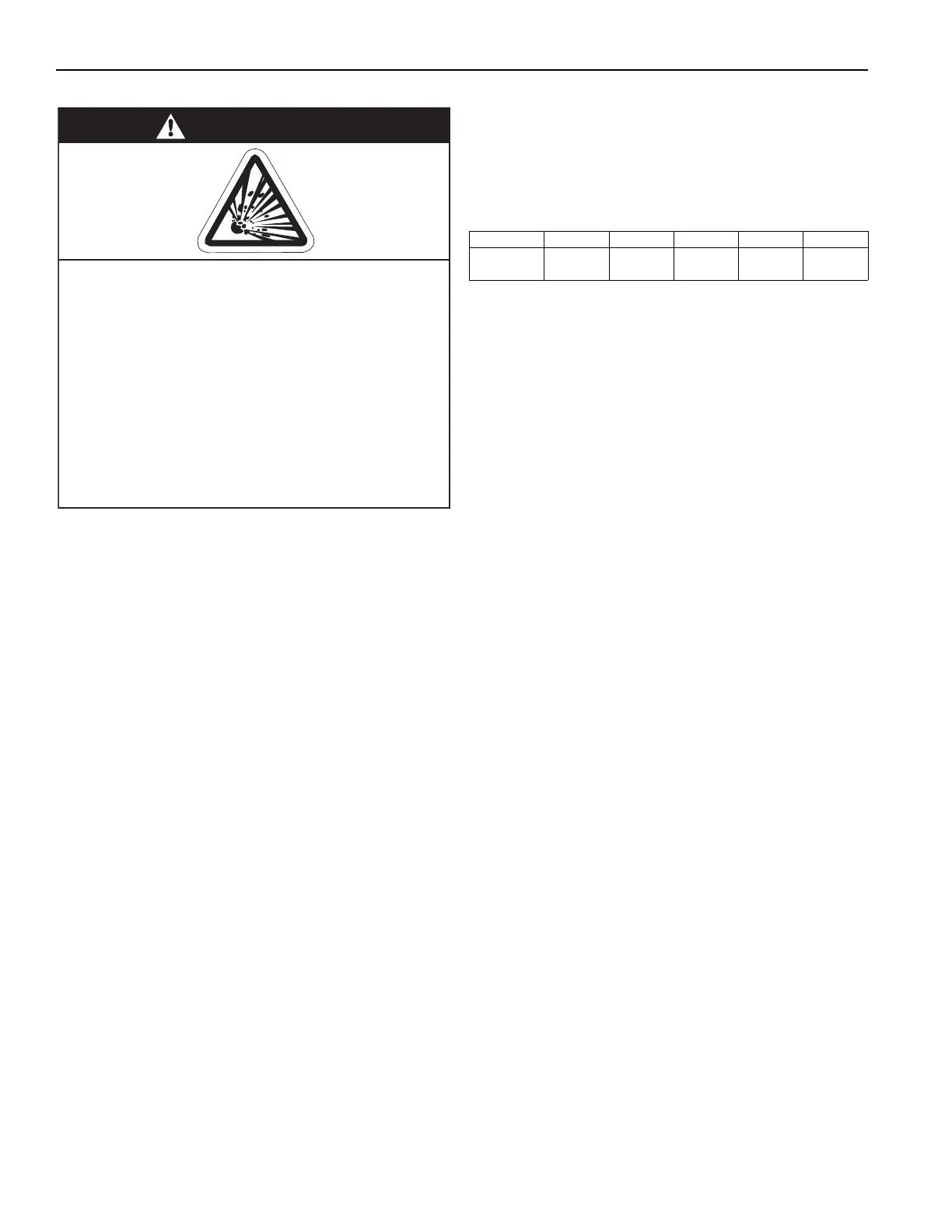

Table 12: Gas Manifold Size

16.3 Gas Manifold Venting

Vent valves fitted on XL compliant manifolds must be

piped to the atmosphere outside the structure and in

accordance with applicable codes. This is the

responsibility of the installer.

16.3.1 Main Gas Regulator Venting

The main regulator used on 1¼" and larger manifolds

must be piped to the atmosphere outside the

structu

re. This is the responsibility of the installer.

16.3.2 Vent Line Installation

The following may be used as a guideline for

installation, but all applicable codes and regulations

must be followed.

•Natural gas and LPG are toxic and flammable

substances. They must be released where they

will not cause personal injury or property damage.

The end of the vent line must be located where it

is safe to release gas.

• Pipe the vent line outside the structure.

• Use as short a vertical run of pipe as possible.

• Do not run pipe from a high point to a lower point

to avoid obstacles.

• Use a minimum number of bends.

• Do not downsize the pipe from the origination

point (must be same size or larger).

•Make sure vent line is free from obstructions.

• Do not group lines together into a common

header.

•The outside termination must have a

weatherproof cap or be directed downward for

protection from the elements and must be

screened to prevent the entry of any objects.

WARNING

Explosion Hazard

Leak test all components of gas piping

before operation.

Gas can leak if piping is not installed

properly.

Do not high pressure test gas piping with air

handler connected.

Failure to follow these instructions can result

in death, injury or property damage.

Model

2005 2010 2010B 2020 2030

Gas NPT

Connection

¾" 1" 1¼" 1½" 2"

Loading...

Loading...