SECTION 16: GAS PIPING

77 of 147

16.4 Gas Piping

The gas manifold extends through the side of the

control cabinet for models 2005 - 2030. The factory

piping terminates with a female pipe connection in

the manual gas valve. The manual main gas shutoff

valve is shipped loose for field installation. A union

must also be installed (supplied by others) between

the supplied manual gas valve main and the first tee

pipe. Be sure that the fuel supply pipe connected at

this point is large enough to ensure the proper gas

flow and line pressure at the inlet of the air handler.

The piping must comply with:

United States: Refer to NFPA 54/ANSI Z223.1 - latest

revision, National Fuel Gas Code.

Canada: Refer to CSA B149.1 - latest revision,

Natural Gas and Propane Installation Code.

Gas supply piping must conform to best building

practices and local codes. During installation of the

gas piping, be sure that no piping restricts

accessibility to the air handler or its removable

access doors.

Lockable manual shut-off val

ve must be added by the

installer in compliance with Occupational Safety and

Health Administration (OSHA) regulations.

16.5 Pressure Test Ports

There are 1/8" (3.2 mm) and 1/4" (6.4 mm) pressure

test ports located on the manifold. The test ports are

available to measure the manifold inlet gas pressure

and the burner gas pressure during burner setup.

16.5.1 Manifold Inlet Gas Pressure

The pressure port for measuring manifold inlet

pressure is located on the inlet side of the first safety

shutoff valve. Refer to the unit rating plate for the

acceptable inlet gas pressure.

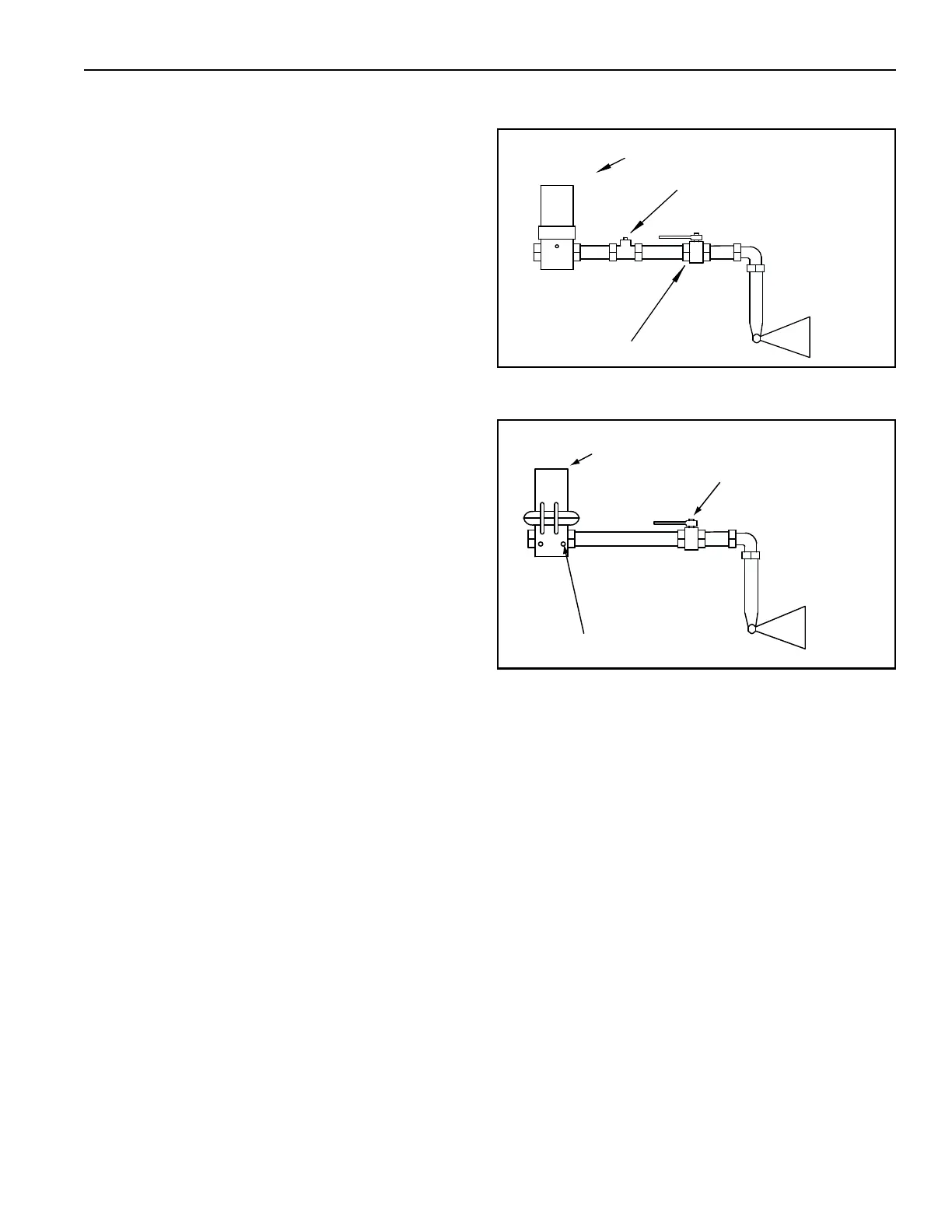

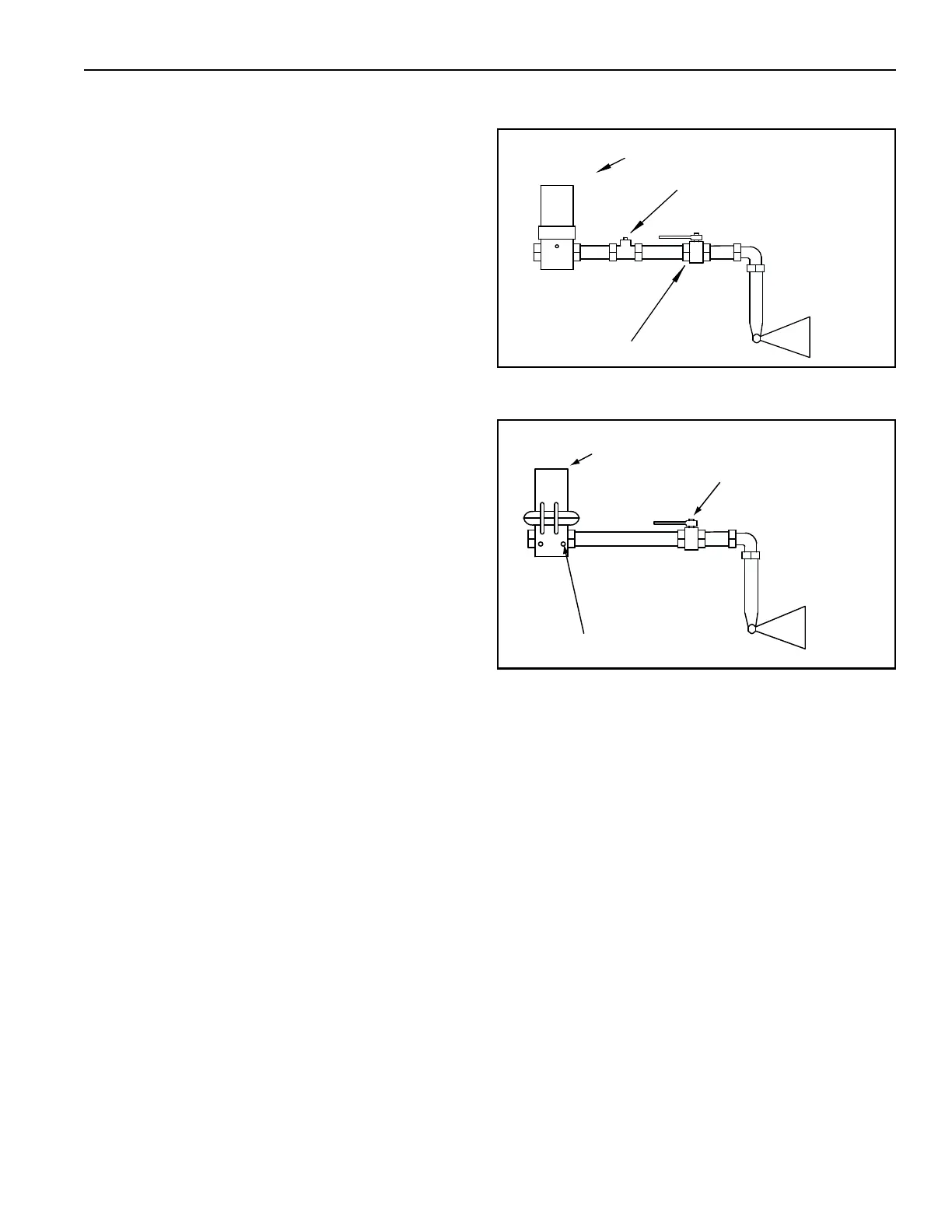

16.5.2 Burner Gas Pressure

A pressure tap is used to measure negative airflow at

the burner and to set high fire gas pressure. On air

handlers equipped with a M611 modulating valve

(Model 2005), the pressure tap is located on a tee

between the M611 valve and the burner. See Page

77, Figure 36 and Page 123, Figure 81. On air

handlers equipped with the MR212 modulating valve

(Models 2010 - 2030), the pressure tap could be

located on the downstream side of the MR212 valve,

on a T-fitting coming off the outlet pressure tap on the

MR212 valve or between the MR212 valve and the

burner. See Page 77, Figure 37 and Page 122,

Figure 79.

FIGURE 36: Plug Tapping (2005)

FIGURE 37: Plug Tapping (2010 - 2030)

16.6 Line Pressure Test - Leak Testing

The air handler and its individual shut-off valve must

be disconnected from the gas supply piping systems

during any pressure testing of that system at test

pressures in excess of 14 in wc (34.9 mbar). The air

handler must be isolated from the gas supply piping

system by closing its individual manual gas valv

e that

is located immediately upstream of the safety shut-off

gas valve.

Burner

Modulating Valve

Manual Gas Valve (Burner)

Plugged Taping

To Measure Burner Pressure

Burner

Modulating Valve

Manual Gas Valve (Burner)

Plugged Taping

Loading...

Loading...