ADF Unit

533

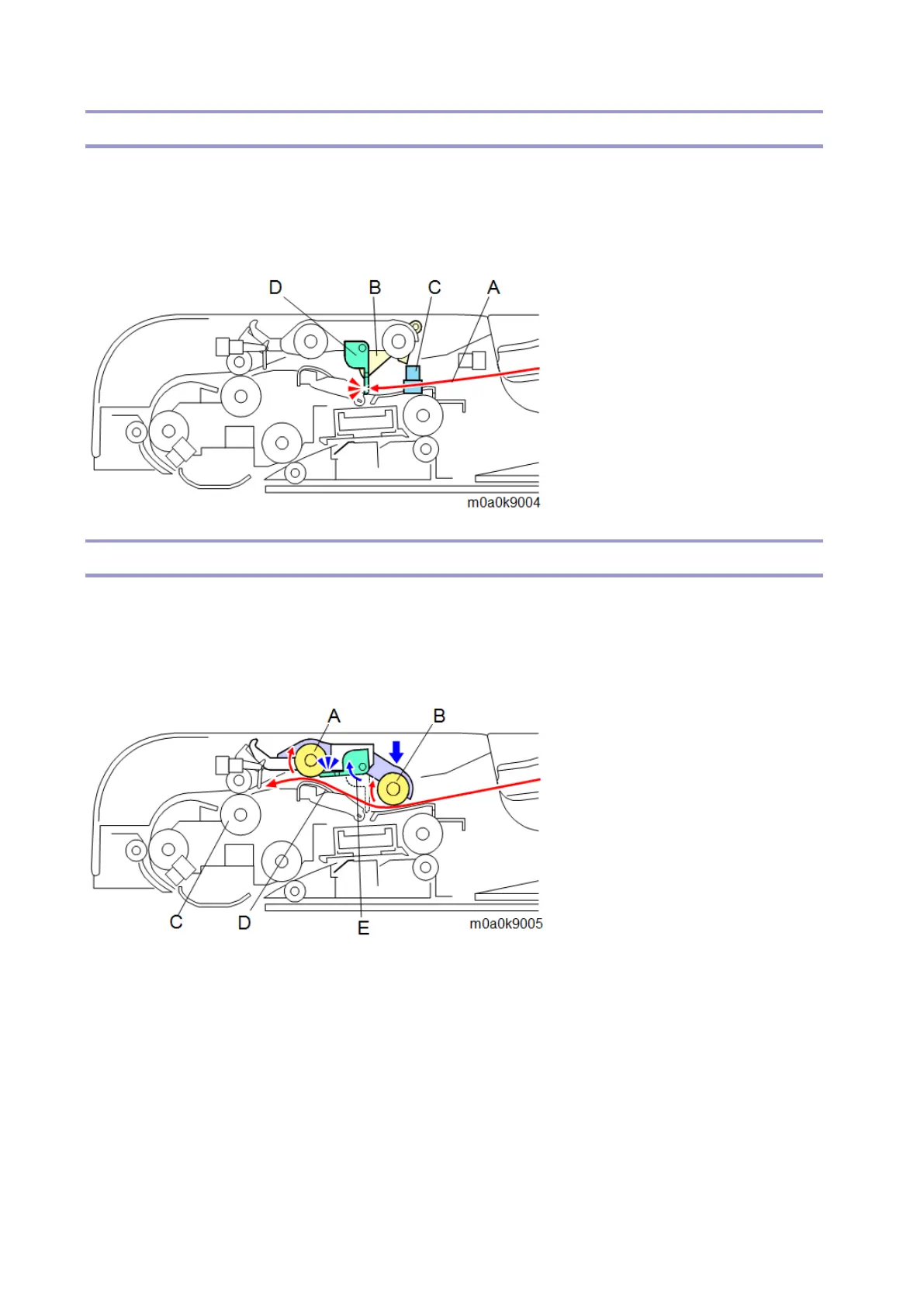

Original Set Detection

When an original [A] is placed on the original tray correctly, the original set sensor actuator [B] is pushed up

and the original set sensor [C] turns off (not interrupted). The machine judges this state as the placement of an

original.

The stopper [D] prevents the user from placing originals too far into the feeder.

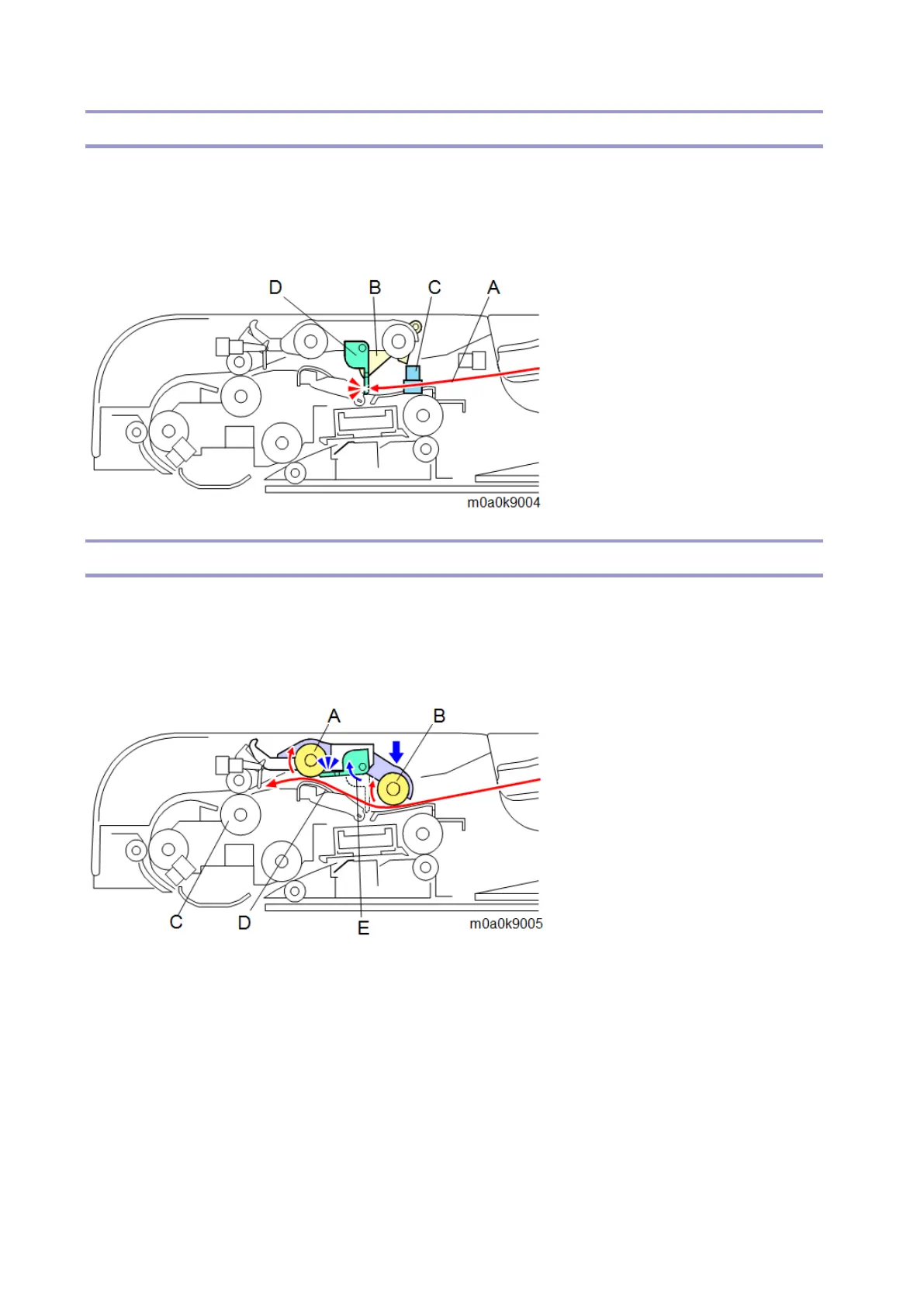

Original Transport Path

When [Start] is pressed, the feed roller clutch is turned ON. Then the feed roller [A] rotates to drop the pick-up

roller [B] onto the top original of the stack. This moves the stopper [E] out of the way, and the original can be

fed from the feed roller [A] to the ADF entrance roller [C].

The friction pad [D] ensures that only one sheet of the original enters the feeder at a time.

When the original reaches the pre-scanning (front side) roller [B] via the ADF entrance roller, the original

moves the feed sensor actuator [C] and the feed sensor [D] is turned ON. Then the feed roller clutch [E] is

turned OFF to stop the feed roller [F] and the pick-up roller [G], to prevent the next original from being picked

up.

Loading...

Loading...