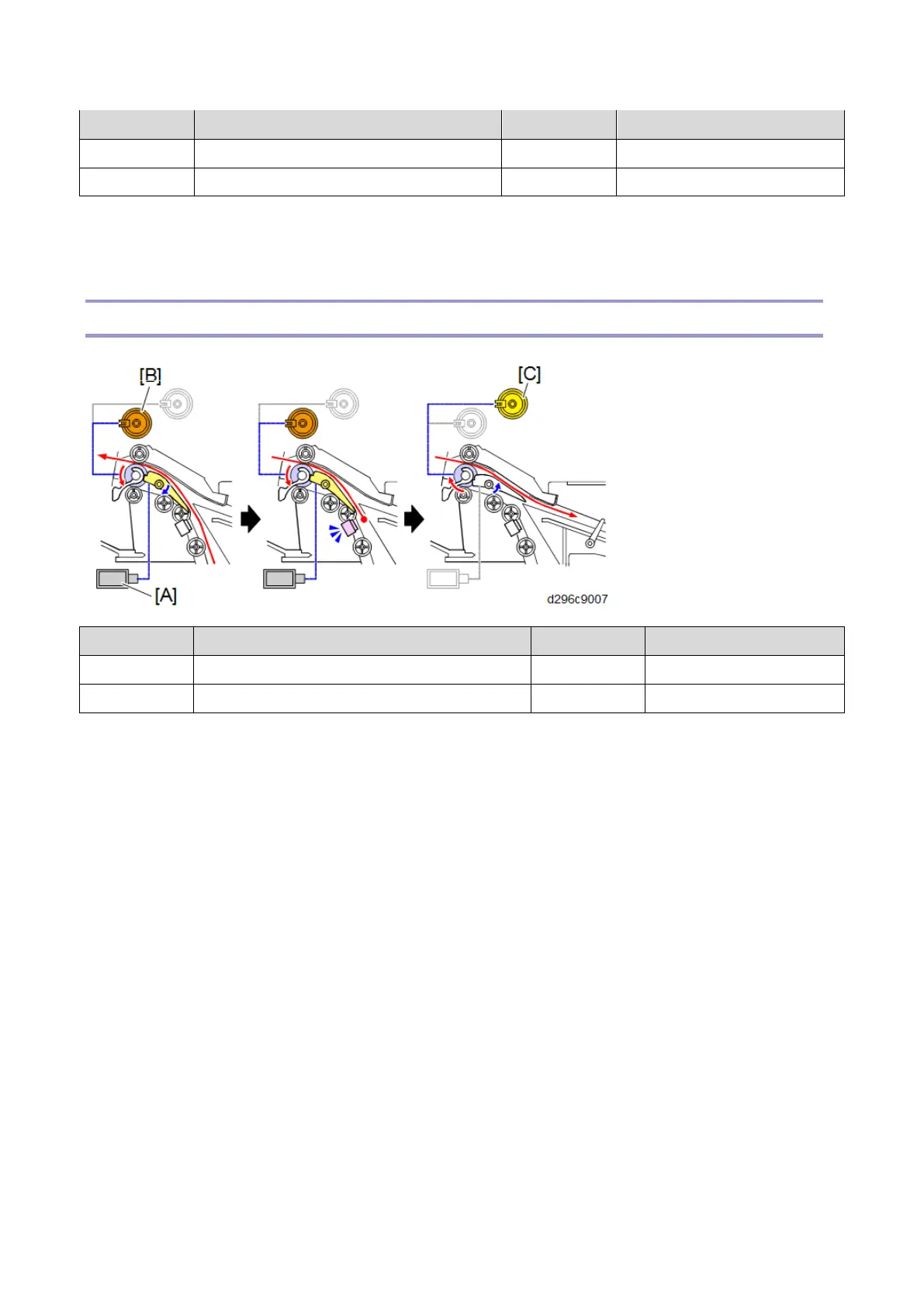

Paper Exit and Inverter

584

Callout Item Callout Item

[A] Paper exit/reverse roller [C] Paper exit sensor

[B] Exit junction gate

The paper transport motor rotates the paper exit/reverse roller [A] through a gear. The paper exit sensor [C]

detects paper exit jams and the paper inversion timing.

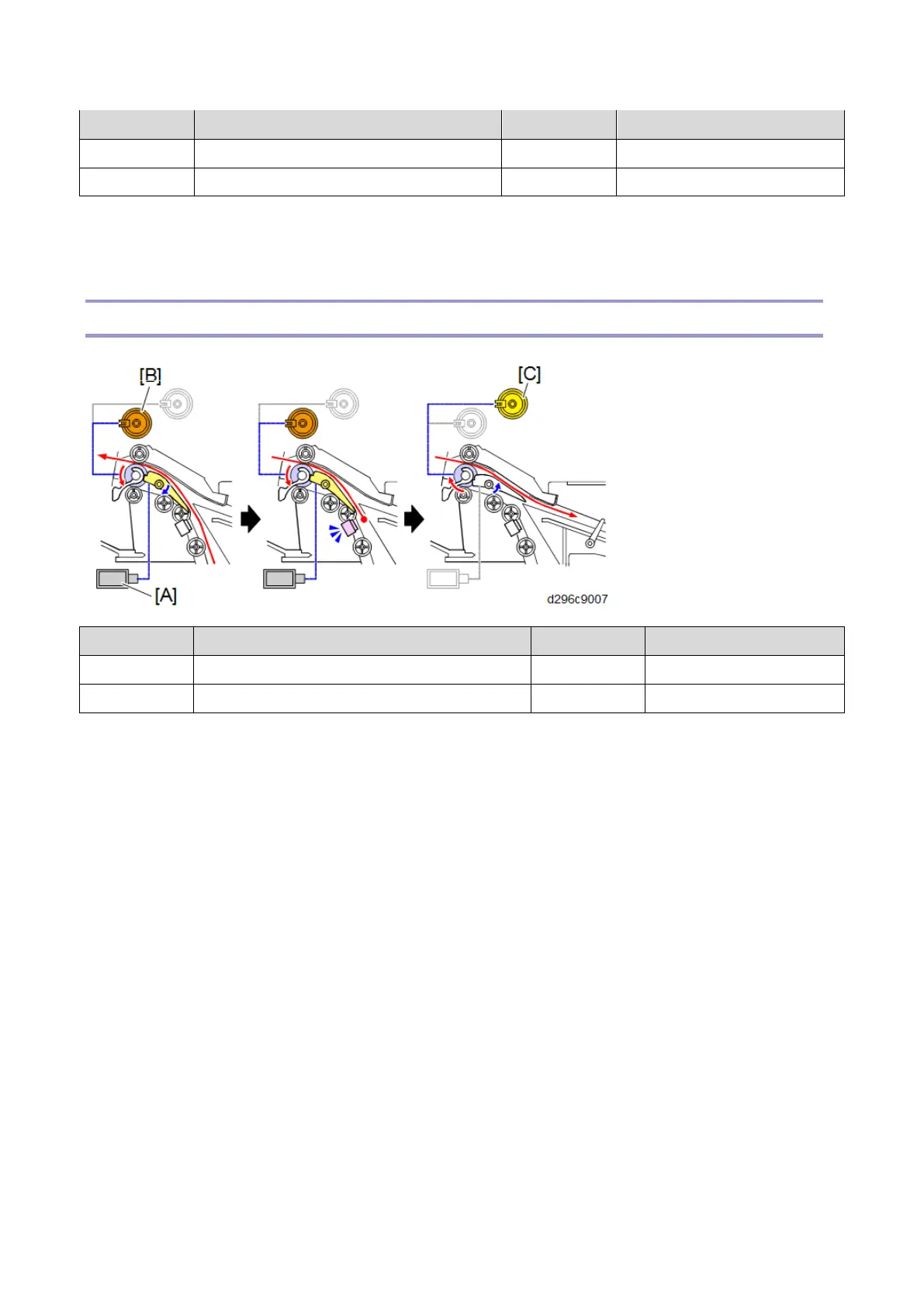

Inverter Operation

Callout Item Callout Item

[A] Exit junction gate solenoid [C] Reverse clutch

[B] Paper exit clutch

The exit junction gate solenoid [A], paper exit clutch [B], and reverse clutch [C] control the exit junction gate

and paper exit/reverse roller simultaneously.

The paper exit clutch and paper reverse clutch transmit the driving to the paper exit inverter roller, in opposite

directions respectively.

The paper exit/reverse roller rotates in the normal direction when the paper exit clutch is turned ON, to feed the

paper to the paper exit path.

When the reverse clutch turns ON, the paper exit/reverse roller rotates in the reverse direction, to feed the paper

to the inverter path or 1-bin exit path (when 1-bin tray unit is installed).

In duplex printing, after the first side of a sheet has been printed, the exit junction gate solenoid turns ON, and

the exit junction gate has been switched to direct the paper to the paper exit path.

And then, the paper exit clutch turns OFF and the paper reverse clutch turns ON, to rotate the paper exit roller

in reverse to feed the paper towards the paper exit (see the left illustration above).

When the trailing edge of the paper passes the paper exit sensor, the machine OFF the inverter junction gate

solenoid, turns ON the paper exit clutch, and turns OFF the reverse clutch. It switches the exit junction gate

back to the original position before the paper completely goes out of the paper exit, and rotates the paper

exit/reverse roller forward to feed the paper to the duplex transport path.

After that, the machine starts to print the second side and feeds out the paper that is printed on both sides to the

Loading...

Loading...