Calibration and Adjustment

Background During calibration, a calibration weight is used to determine how much the

displayed value deviates from the actual measurement value. This deviation is

compared with an entered target value and is then eliminated by a subsequent

adjustment of the balance. During the Linearization, the deviation of the values

from the ideal characteristic curve is cleared.

Not all functions/settings can be selected on balances used as legal measuring

instruments.

When and how often Calibration/adjustment should be carried out on a regular basis, e. g., daily after

the balance is turned on. In addition, it should be done after each leveling and

always when the ambient conditions have changed (temperature, humidity, or air

pressure), and when the balance has been set up in another location.

isoCal All Cubis balances are equipped with the automatic calibration function isoCal

(time and temperature-controlled). You can adapt this function according to your

requirements. You can set up a memory function that triggers a prompt for

calibration/adjustment at specified intervals.

h

The process for the calibration/adjustment function may differ depending on the

preset configuration (see System Settings > Calibration/Adjustment Data).

The factory settings have not been changed for the procedure described here.

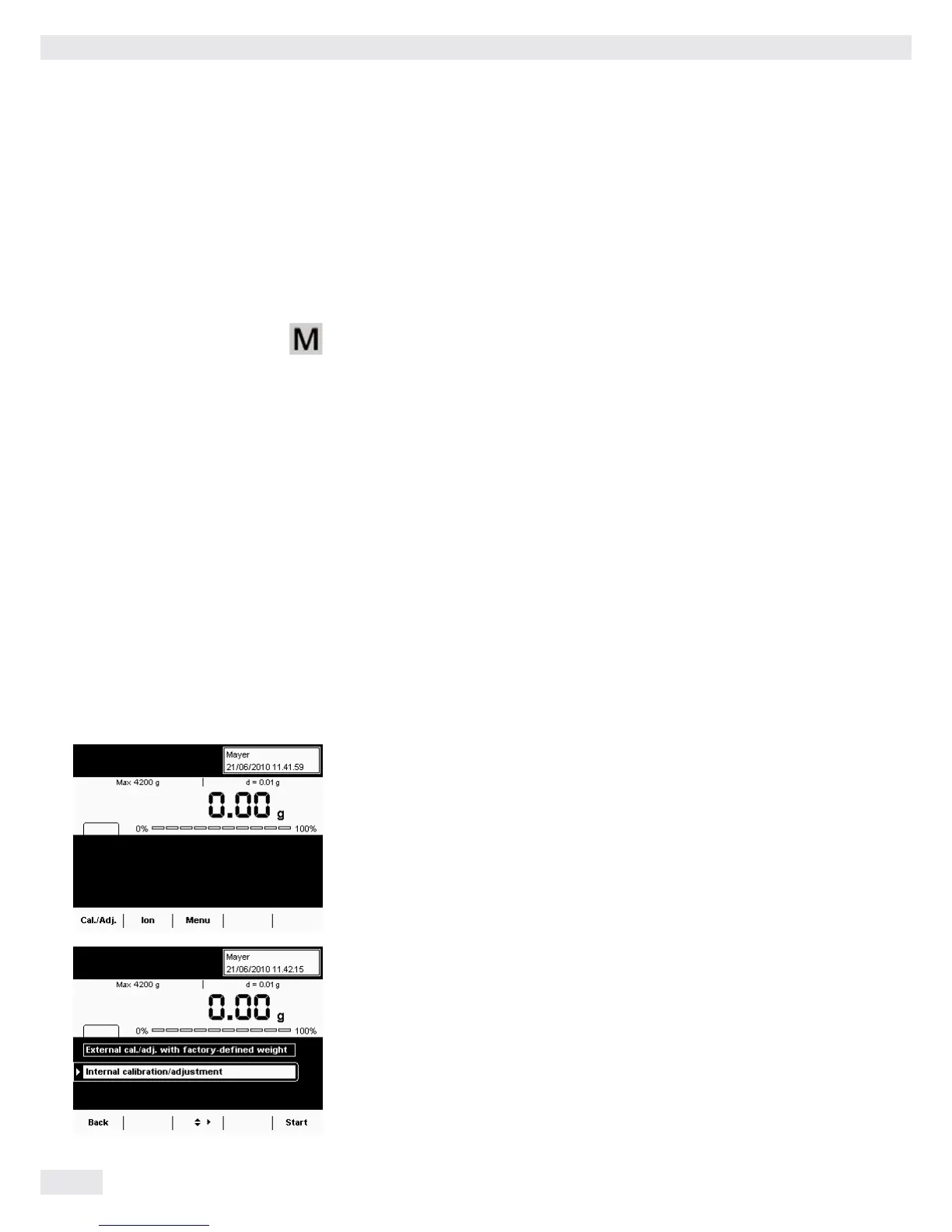

Calibration/Adjustment Using Internal

Calibration Weight

t If required, switch to operating mode.

t Make sure that the weighing pan is empty.

J t Press TARE to tare the balance.

t Select Cal./Adj.

t Select Internal calibration/adjustment or, if this option is already

marked, select Start.

Calibration/Adjustment

116 Cubis MSU User Manual

Loading...

Loading...