Section 06 LUBRICATION SYSTEM

Sub-Section 03 (OIL INJECTION PUMP)

06-03-5

All Engines

Start and bring engine to normal operating tem-

perature.

Adjust idle speed to specification. Refer to FUEL

SYSTEM 05-04.

Stop engine.

Final Synchronization

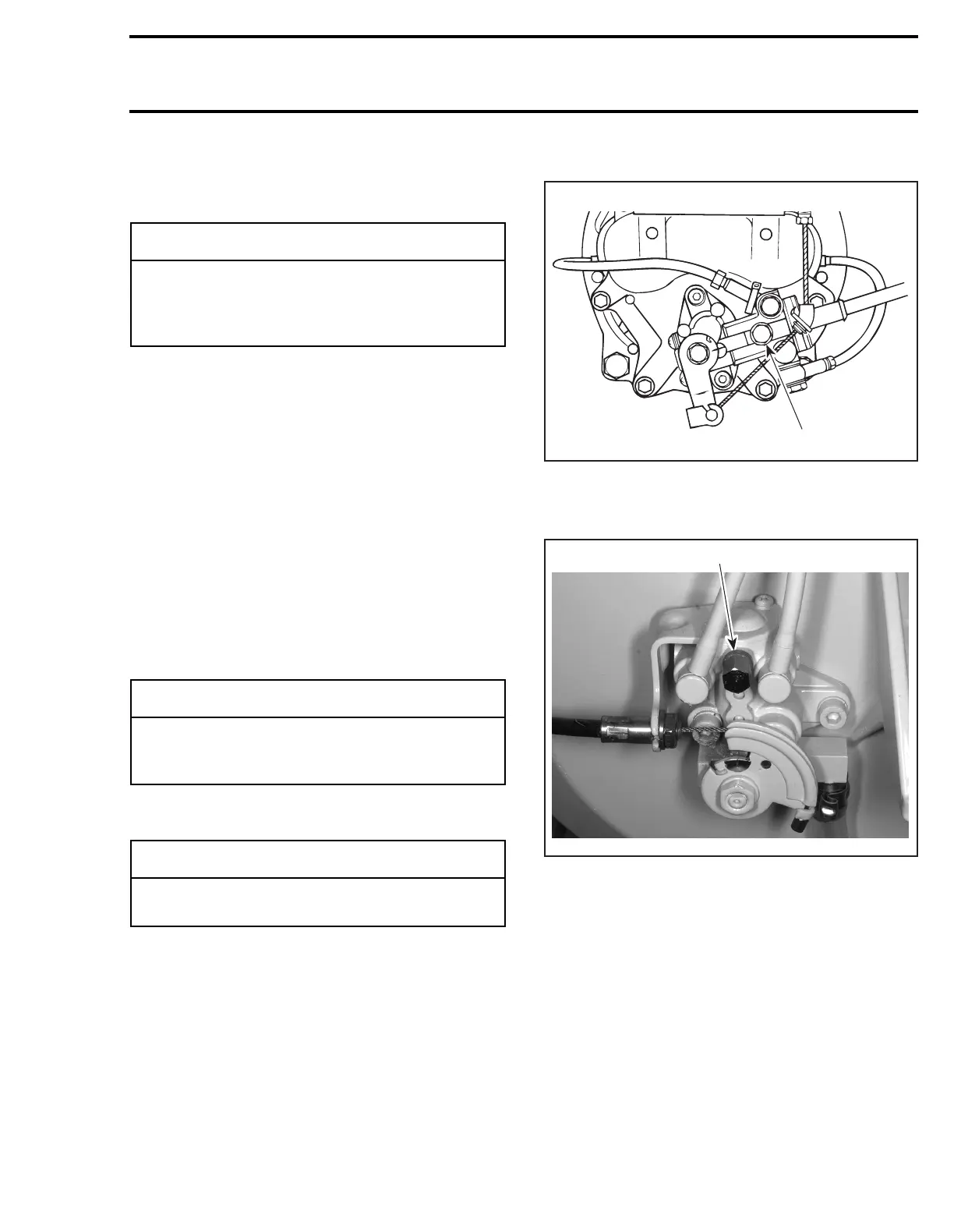

Eliminate throttle cable free-play by depressing

throttle lever until a slight resistance is felt. In this

position, marks on pump body and lever must

align.

NOTE:

A mirror may be used to facilitate this ver-

ification.

If necessary, turn cable adjustment screw to ob-

tain pump mark alignment. Refer to above illustra-

tions.

Tighten jam nut and recheck alignment marks.

Bleeding

Ensure oil injection reservoir is sufficiently filled.

Install a dry rag below oil injection pump.

Loosen bleed screw to allow oil to flow.

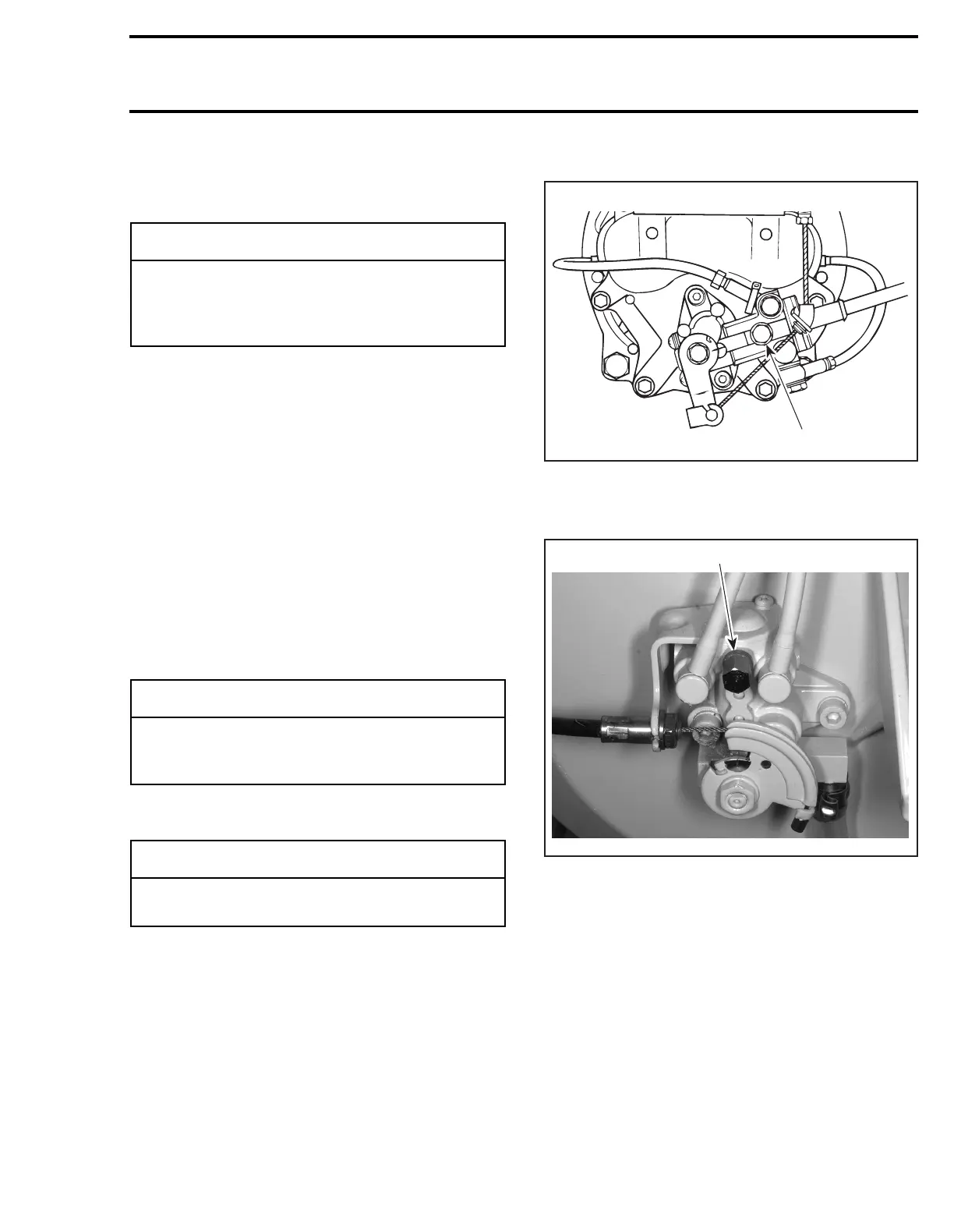

717 Engines

TYPICAL

1. Bleed screw

787 Engine

1. Bleed screw

All Engines

Keep bleeding until all air has escaped from line.

Make sure no air bubbles remain in oil supply line.

Tighten bleed screw.

Wipe any oil spillage.

Check small oil lines between pump and intake

manifold. They must be full of oil.

-

CAUTION

If watercraft is out of water, engine must be

cooled using the flush kit. If air bubbles are

present in the oil injection system, bleed

system before operating engine.

-

CAUTION

Proper oil injection pump adjustment is very

important. Any delay in the opening of

pump can result in serious engine damage.

-

CAUTION

Oil injection system must be bled and ad-

justment checked before operating engine.

1

F01D4SC

F07G02A

1

Loading...

Loading...