Section 03 ENGINE

Sub-Section 08 (EXHAUST SYSTEM)

03-08-6

SPX Model Only

Move tuned pipe cone

no. 12

in front of bilge be-

tween body and fuel tank.

Open storage cover and remove basket. Then,

pull out tuned pipe cone

no. 12

through storage

compartment opening.

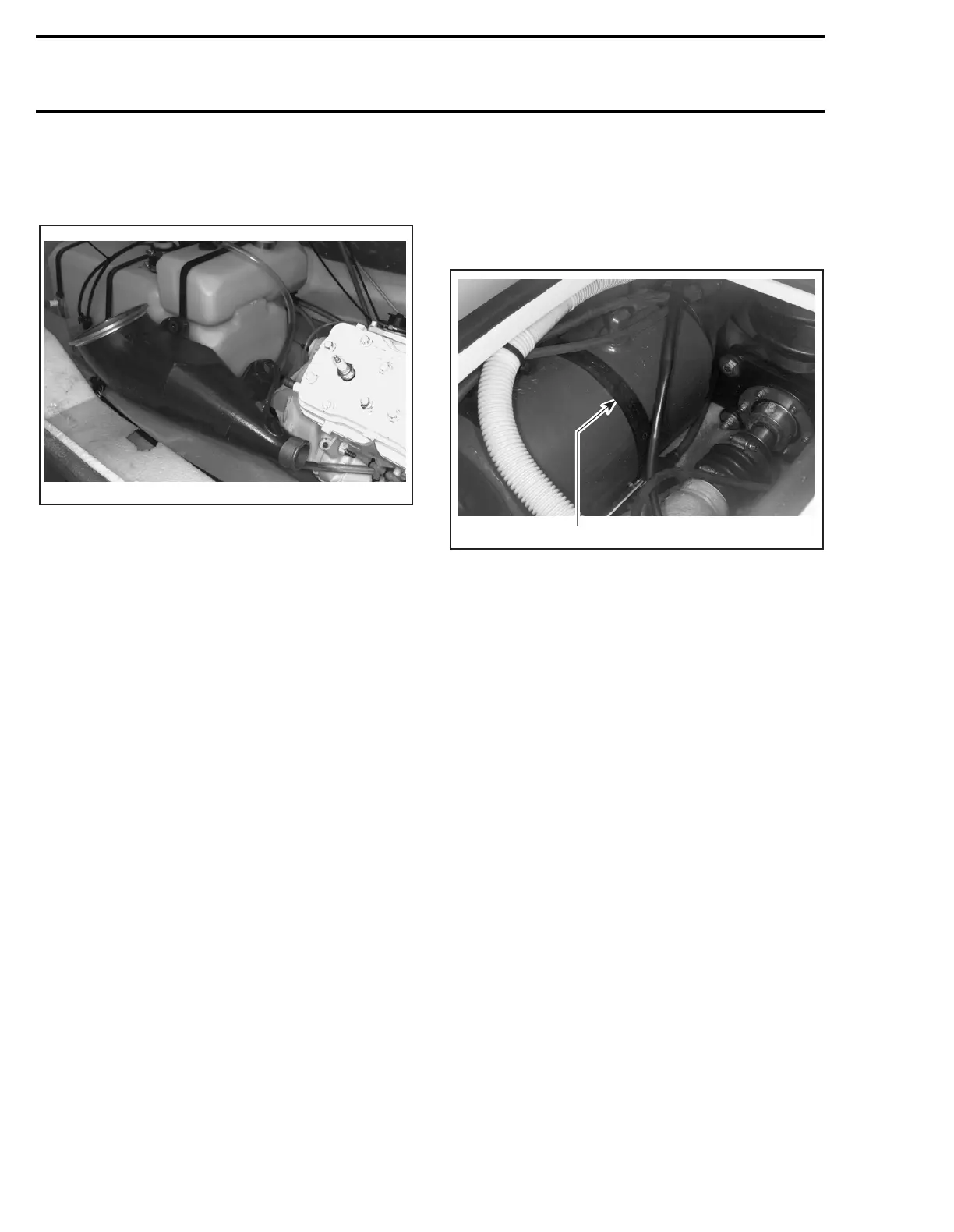

XP, GSX and GTX Models

Remove tuned pipe cone

no. 12

from engine

compartment.

EXHAUST MANIFOLD REMOVAL

SPX, XP, GSX and GTX Models

Remove air intake silencer and carburetors. Refer

to FUEL SYSTEM 05-03 for proper procedure.

All Models

Remove eight screws

no. 14

and lock washers

no. 24

then withdraw exhaust manifold.

MUFFLER REMOVAL

All Models Except the HX and XP

Disconnect hoses from muffler.

Disconnect hoses of the water flow regulator

valve (787 engines).

Disconnect retaining strap

no. 2

of muffler.

Pull muffler

no. 13

out of bilge.

HX Model Only

Loosen exhaust hose collar

no. 1

at tuned pipe

cone outlet (only if tuned pipe cone is not re-

moved).

Remove rear access cover from body.

Disconnect upper exhaust hose

no. 25

in front of

muffler.

Disconnect both water injection hoses and both

water drain hoses from muffler.

Disconnect retaining strap

no. 2

of muffler.

1. Strap

Pull muffler

no. 13

out of bilge.

NOTE:

Lower exhaust hose of muffler may be

disconnected or left with muffler.

TUNED PIPE REPAIR

This procedure is given to repair tuned pipe cracks

using T.I.G. welding process.

Procedure

– Sand the cracked area to obtain bare metal.

– Perform a 1.50 mm (1/16 in) depth chamfer

over crack.

– Use pure argon gas with 5.55 mm (3/32 in)

tungsten electrode (puretung “green”, zirtung

“brown”) and AC current.

– Use a 5.55 mm (3/32 in) aluminum welding rod

(no. 4043), to fill crack.

– Sand welding slightly to remove material sur-

plus.

Test

– Use compressed air at 124 kPa (18 PSI) to pres-

surize tuned pipe.

F01D7JA

F05D07A

1

Loading...

Loading...