Section 08 PROPULSION SYSTEM

Sub-Section 03 (DRIVE SYSTEM)

08-03-8

SPX, GSX AND GTX MODELS

1. PTO flywheel remover

Install the extension handle (P/N 295 000 125) on

the PTO flywheel remover. Loosen PTO flywheel

COUNTERCLOCKWISE when facing it.

DISASSEMBLY

HX and XP Models

13,14, Seal and Needle Bearing

Bearing and seals can be easily removed using

the bearing/seal remover tool (P/N 295 000 144).

NOTE:

The same tool is used for bearing and seal

removal of jet pump.

Properly support seal carrier when removing seals

and bearing.

PARTS INSPECTION

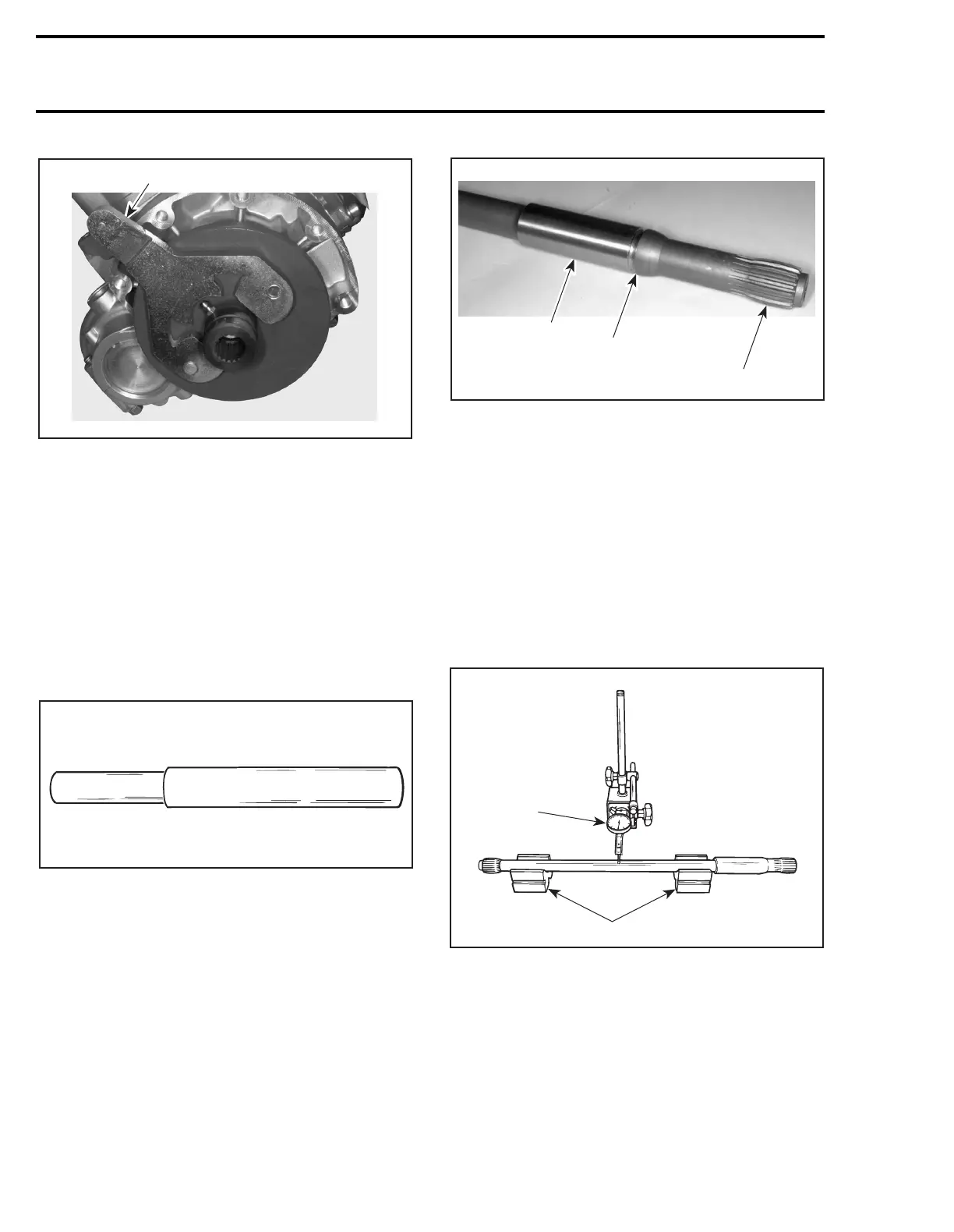

3, Drive Shaft

Inspect condition of splines.

Inspect condition of groove.

With your finger nail, feel contact surface of float-

ing ring. If any irregular surface is found, renew

drive shaft.

1. Floating ring contact surface

2. Groove condition

3. Splines condition

Excessive deflection could cause vibration and

damage to drive shaft splines, impeller, flywheel

or floating ring.

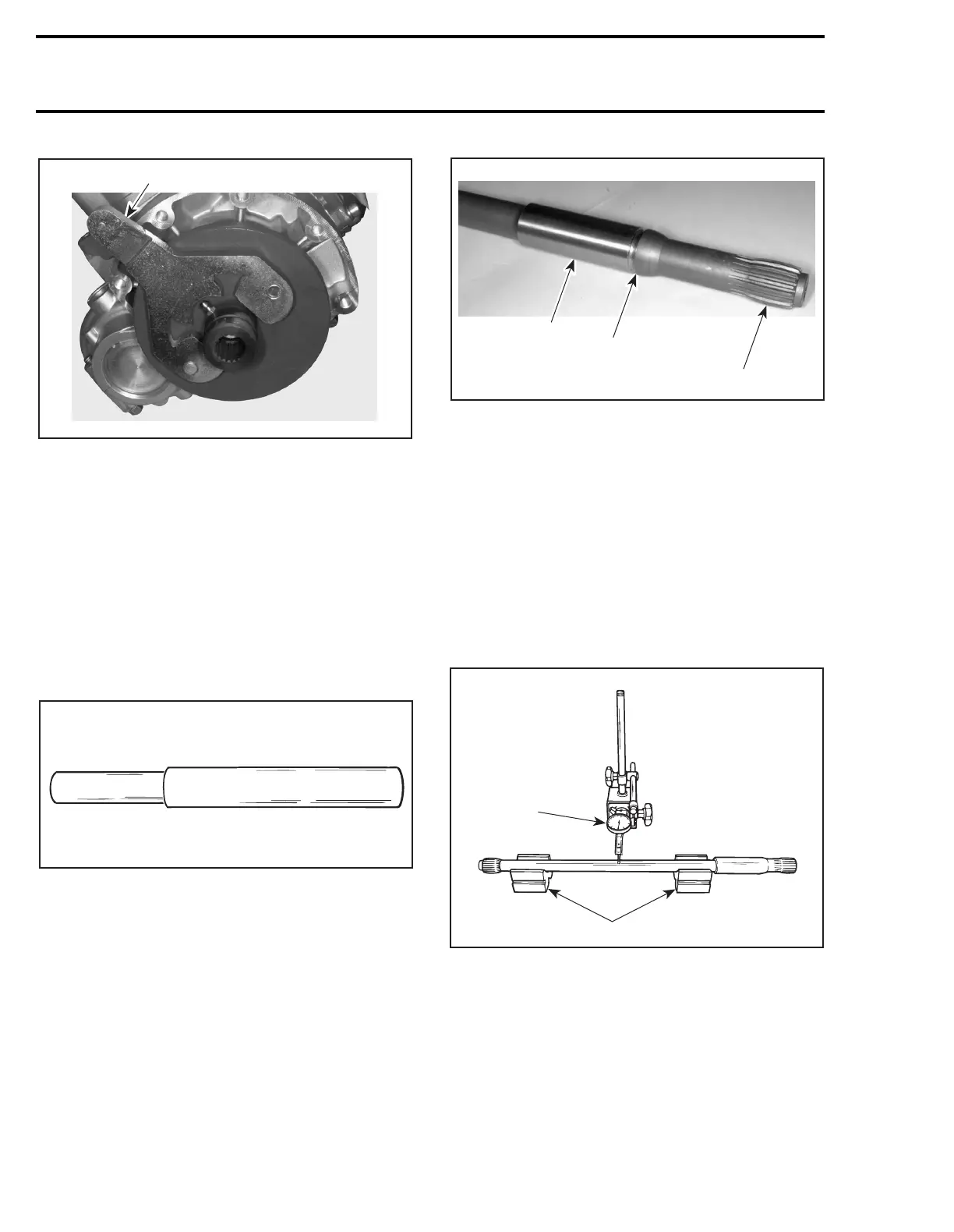

Place drive shaft on V-blocks and set-up a dial

gauge in center of shaft. Slowly rotate shaft; dif-

ference between highest and lowest dial gauge

reading is deflection. Refer to the following illus-

tration.

Maximum permissible deflection is 0.5 mm

(.020 in).

MEASURING DRIVE SHAFT DEFLECTION

1. Dial gauge

2. V-blocks

15, Damper

Visually inspect shape of dampers for deformation

or other damage.

F06I02A

1

F01J11A

F01I0FA

3

2

1

F01J15A

1

2

Loading...

Loading...