Section 03 ENGINE

Sub-Section 06 (BOTTOM END)

03-06-3

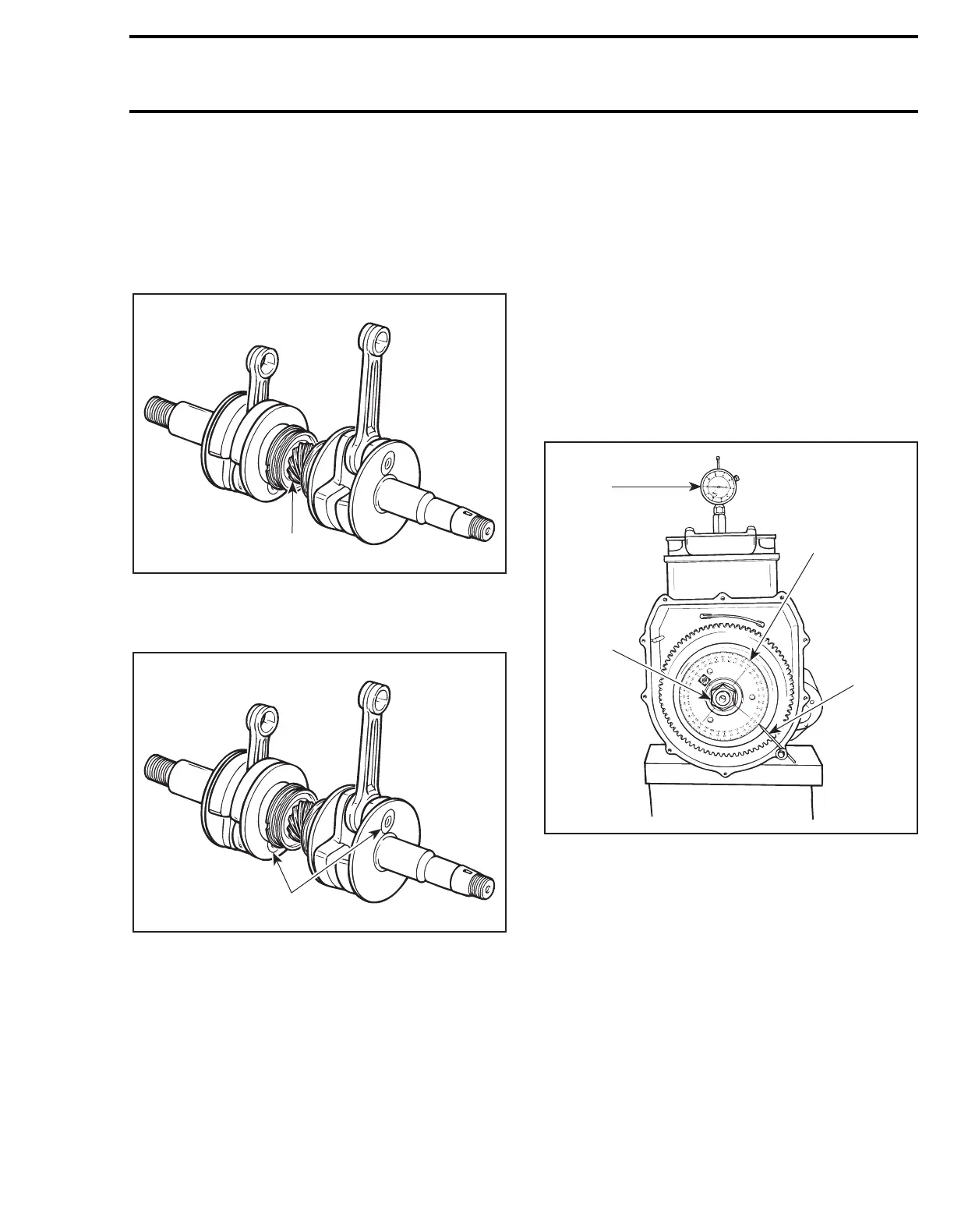

CRANKSHAFT MISALIGNMENT

AND DEFLECTION

Since it is an assembled crankshaft it can become

misaligned or deflected. Crankshaft can be twist-

ed on center main journal, changing timing of one

cylinder in relation with the other.

1. Main journal alignment here

Counterweights can also be twisted on connect-

ing rod journal on any or both cylinder(s).

1. Connecting rod journal alignment here

Crankshaft Alignment at Center Main

Journal

NOTE:

The following checks can be performed

with engine in watercraft without overhauling en-

gine.

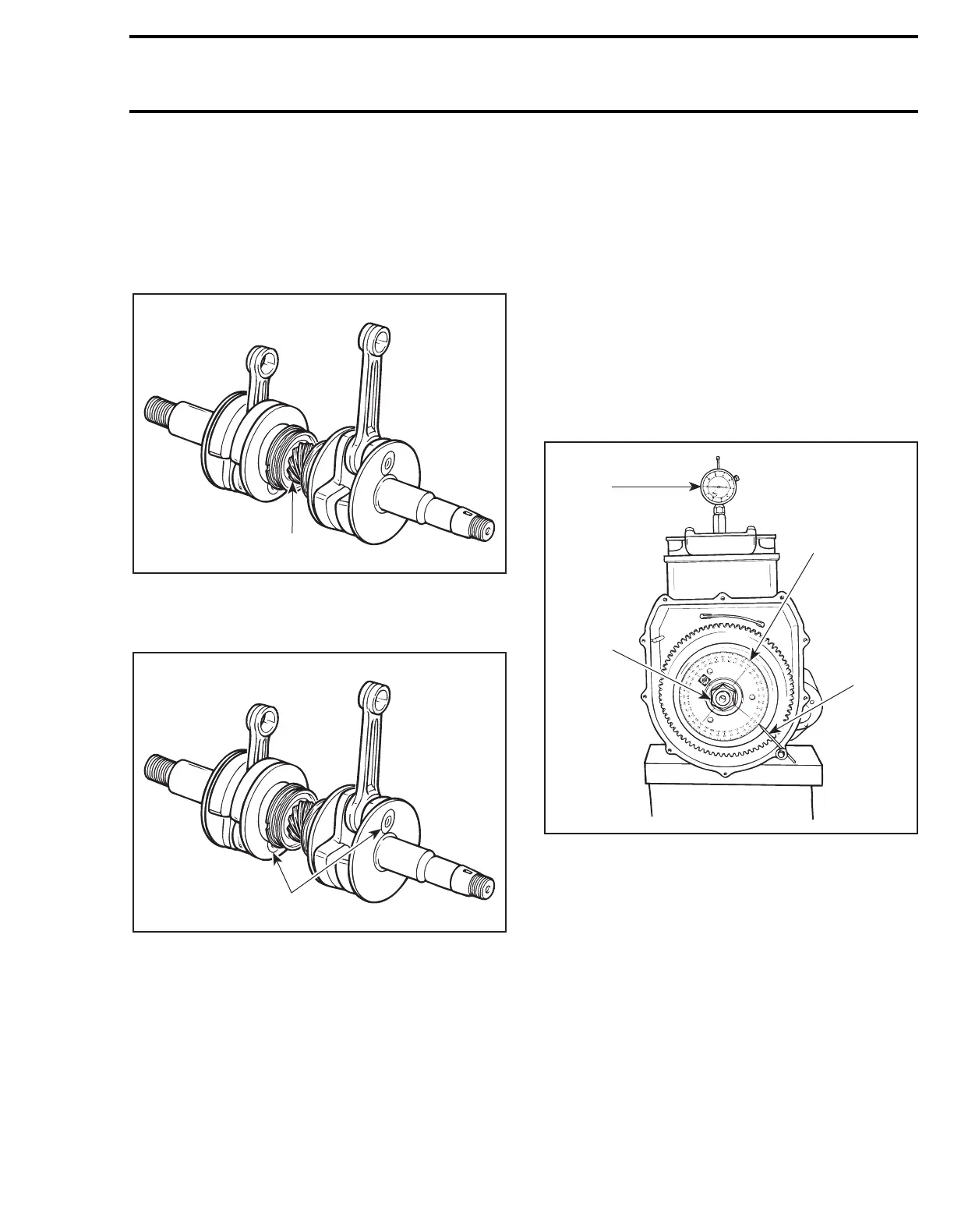

To accurately check if crankshaft is twisted on

center main journal, proceed as follows:

– Remove magneto housing cover.

– Remove flywheel nut (and magneto rotor for

the 787 engine). Refer to ENGINE 03-04 for

procedures.

– Install Bombardier degree wheel (P/N 295 000

007) on crankshaft end. Hand-tighten nut only.

– Remove both spark plugs.

– Install a TDC gauge in spark plug hole on

MAG

side

.

– Bring

MAG

piston at Top Dead Center.

– As a needle pointer, secure a wire with a cover

screw and a washer.

– Rotate degree wheel (NOT crankshaft) so that

needle pointer reads 360°.

1. TDC gauge

2. Degree wheel

3. Hand tighten nut

4. Needle pointer

– Remove TDC gauge and install on

PTO side

.

– Bring

PTO

piston at Top Dead Center.

Interval between cylinders must be exactly 180°

therefore, needle pointer must indicate 180° on

degree wheel (360° - 180° = 180°).

Any other reading indicates a misaligned crank-

shaft.

F01D1NA

1

F01D1NB

1

1

F01D4IA

3

2

4

Loading...

Loading...