Section 06 LUBRICATION SYSTEM

Sub-Section 03 (OIL INJECTION PUMP)

06-03-4

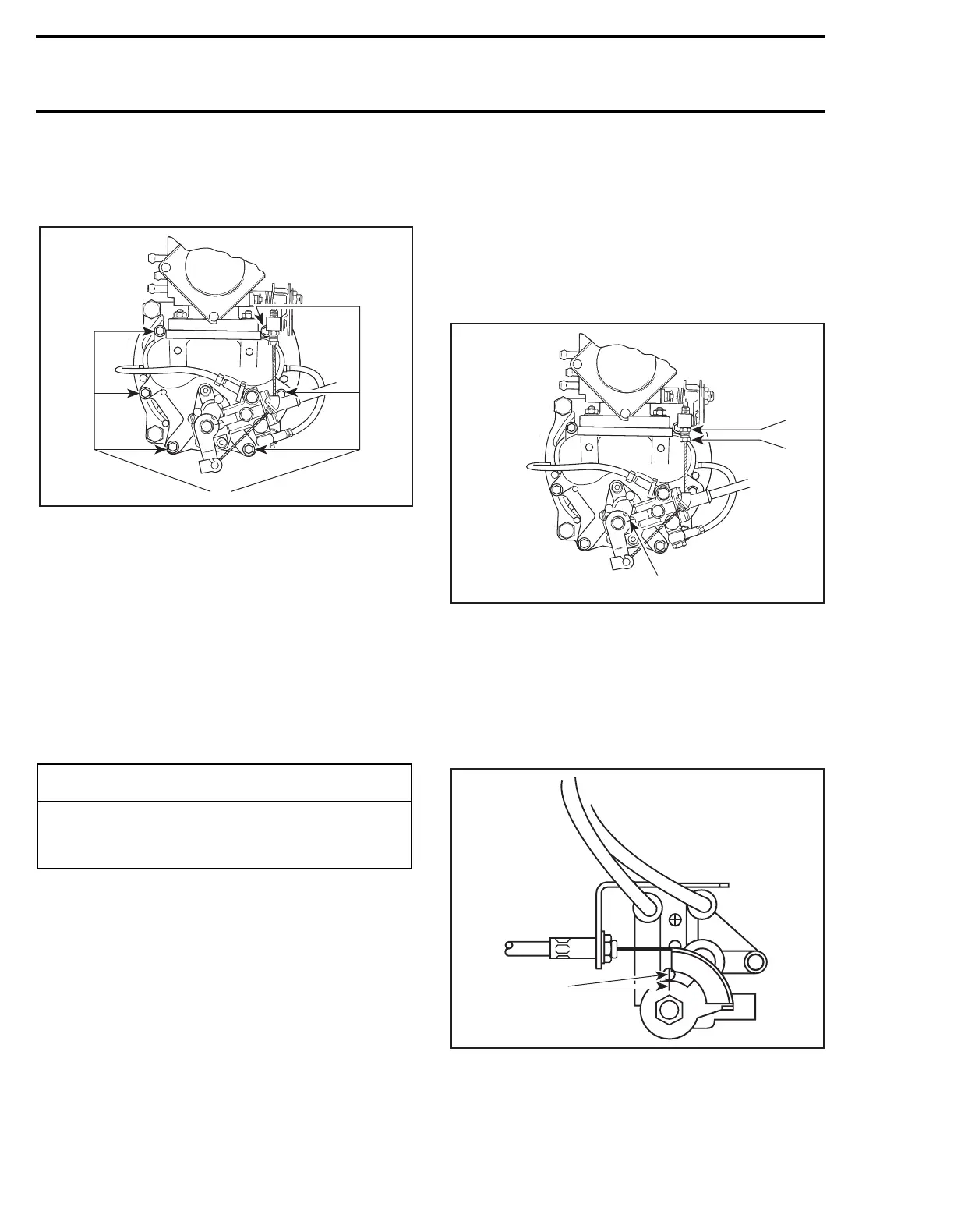

4, Intake Manifold

Install intake manifold to rotary valve cover and

torque screws

no. 6

to 10 N•m (89 lbf•

in

).

TYPICAL

A. 10 N•m (89 lbf•in)

787 Engine

10,11, Oil Injection Pump and Shaft

Install shaft

no. 11

in crankshaft end.

Install pump. Secure with flat washers

no. 9

and

screws

no. 8

. Torque to 3 N•m (26 lbf•

in

).

Install oil injection pump cable.

ADJUSTMENTS

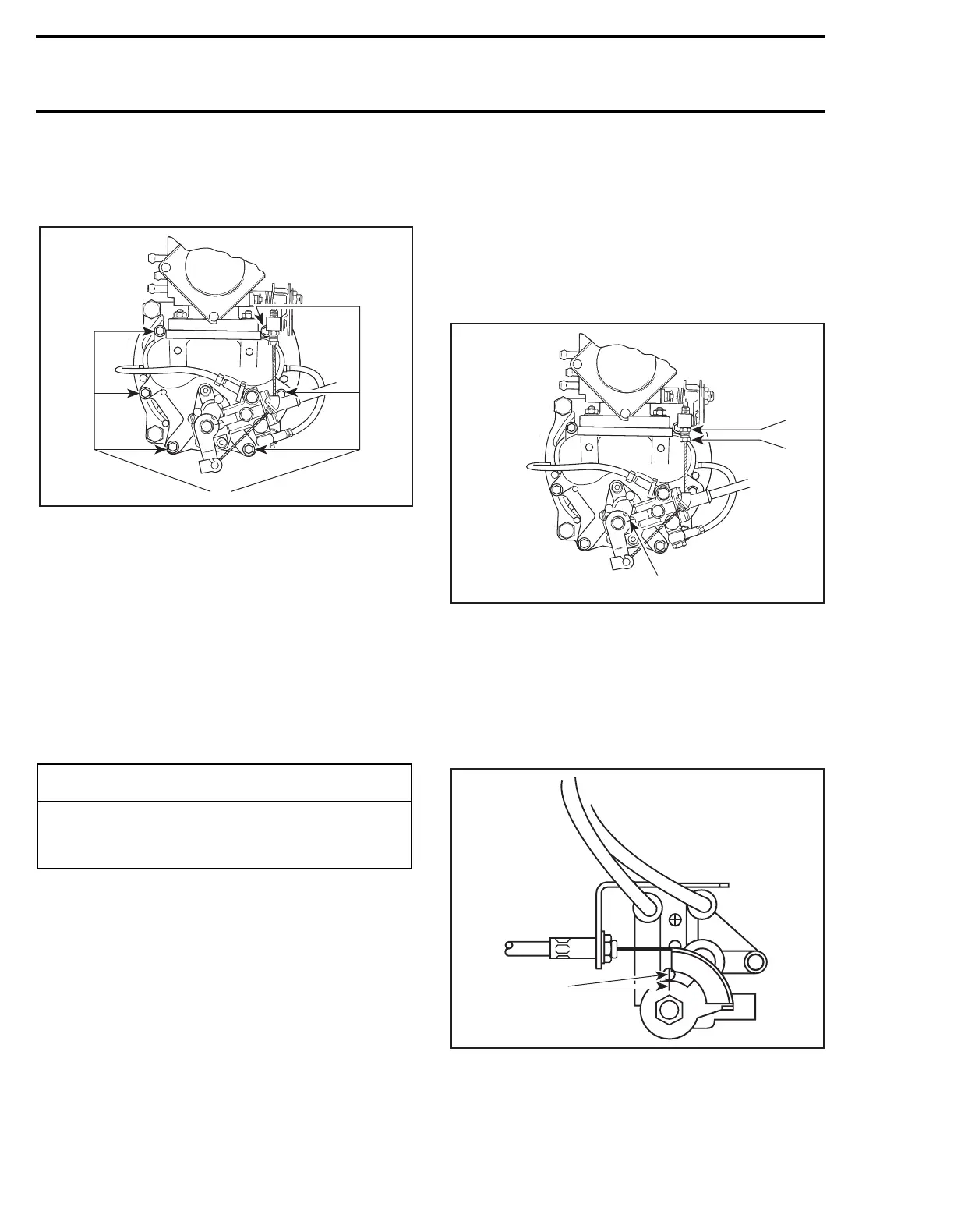

Preliminary Synchronization

NOTE:

To check synchronization of pump as a

routine maintenance, refer to

Final Synchroniza-

tion

. Make sure idle speed of engine is properly

adjusted.

Ensure carburetor butterfly(ies) is (are) in closed

position.

NOTE:

On a twin carburetor engine, make sure

carburetors are properly synchronized. If neces-

sary, refer to FUEL SYSTEM 05-04.

Turn idle speed screw until it contacts stopper.

Turn idle speed screw 2 turns.

Turn cable adjustment nut to align marks on

pump.

NOTE:

A mirror may be used to facilitate this ver-

ification.

717 Engines

TYPICAL

1. Jam nut

2. Adjustment nut

3. Aligned marks

787 Engine

NOTE:

The adjustment screw and jam nut for the

oil injection pump cable are located at PTO carbu-

retor lever.

TYPICAL

1. Aligned marks

-

CAUTION

As oil injection pump adjustment is depen-

dent on throttle cable position, make sure to

perform throttle cable adjustment first.

F01D4RC

A

F01D4RE

2

3

1

F01G0RA

1

Loading...

Loading...