Section 03 ENGINE

Sub-Section 06 (BOTTOM END)

03-06-9

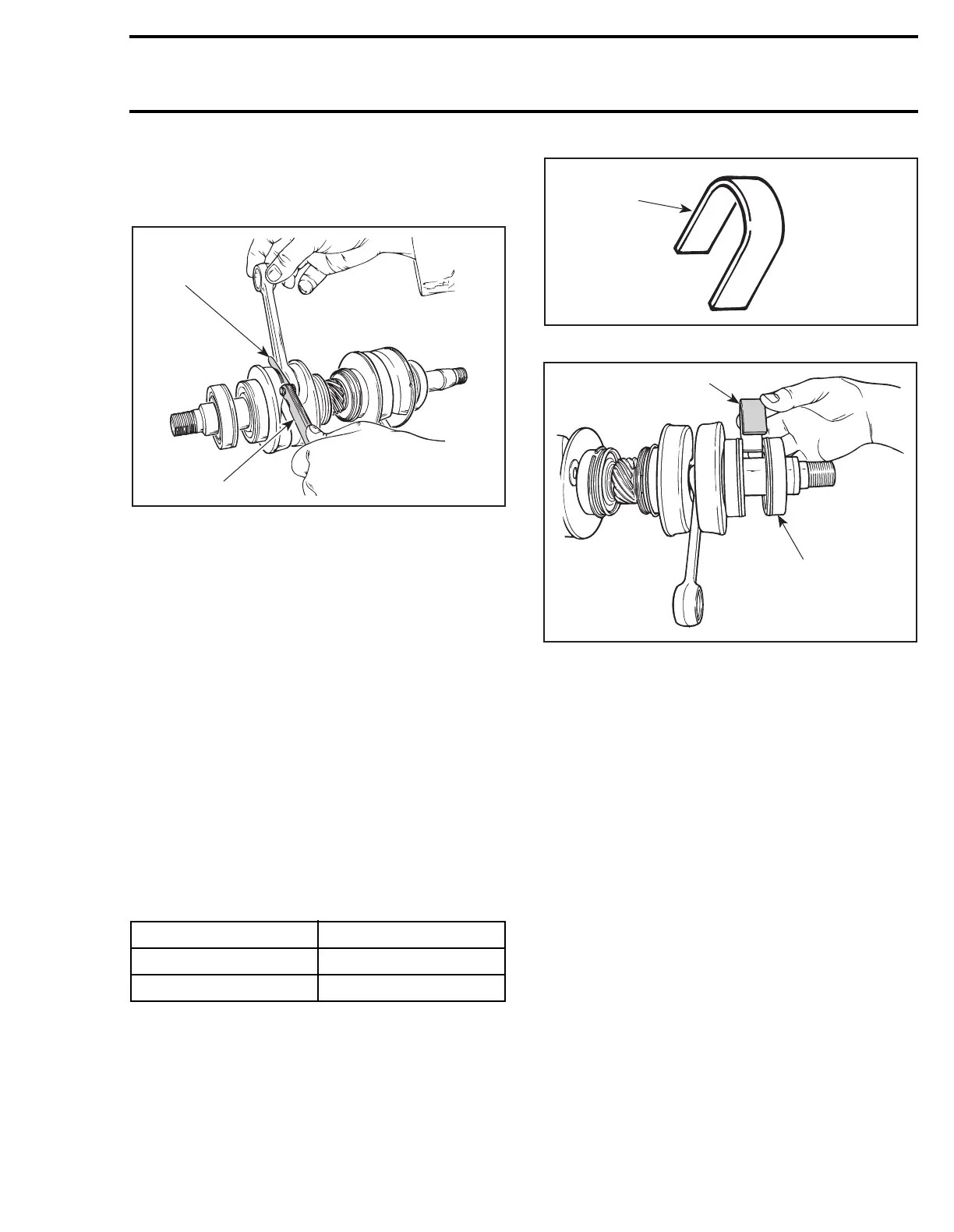

Connecting Rod Big End Axial Play

Using a feeler gauge, measure distance between

thrust washer and crankshaft counterweight.

1. Measuring big end axial play

2. Feeler gauge

ASSEMBLY

Assembly is essentially the reverse of disassem-

bly procedures. However pay particular attention

to the following.

2,4,5,14, Bearing and Crankshaft

Apply Loctite 767 anti-seize on part of crankshaft

where bearing fits.

Prior to installation, place bearings into a container

filled with oil, previously heated to 75°C (167°F).

This will expand bearing and ease installation.

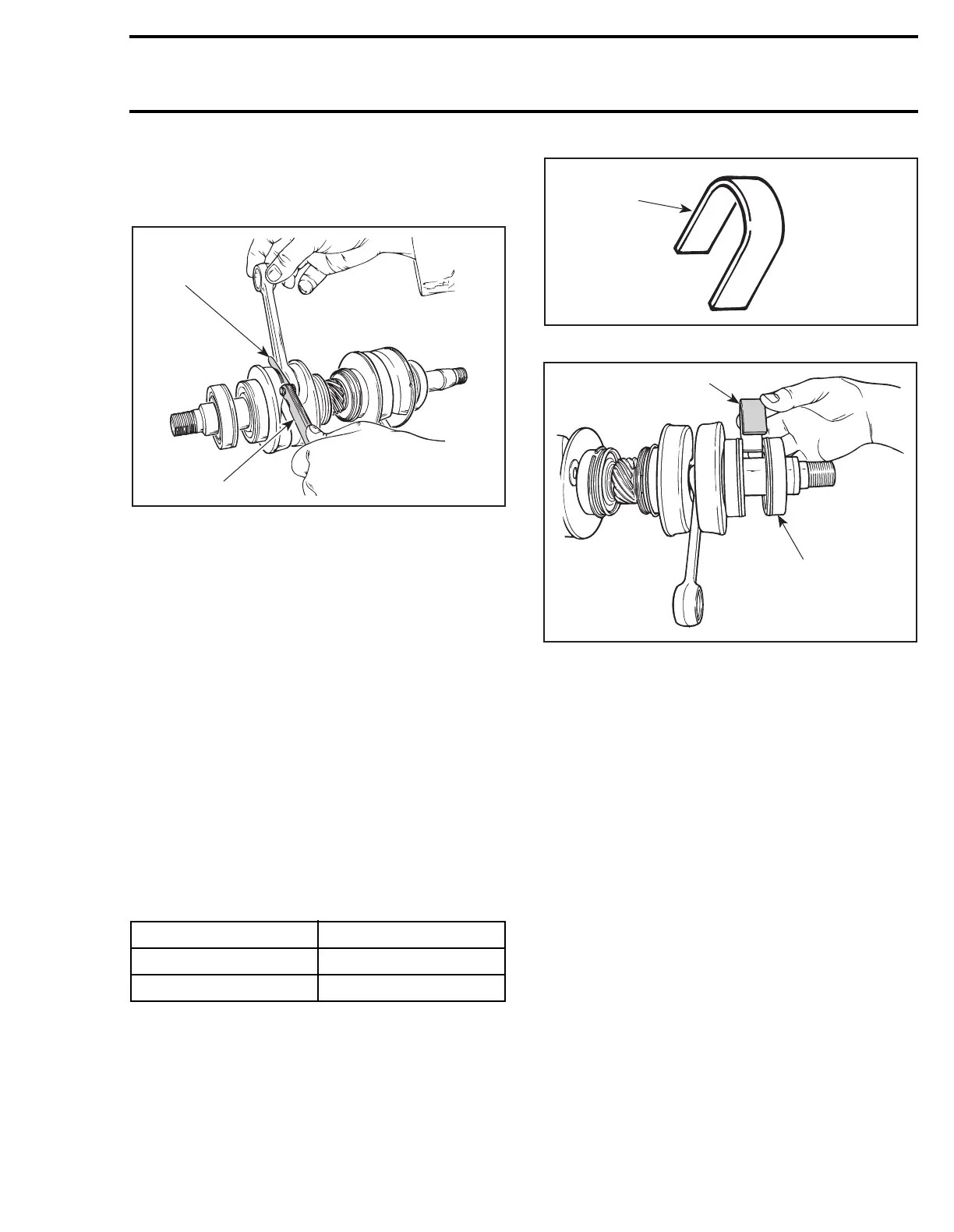

To properly position the outer PTO side bearing

no. 5

on 717 engines or the outer MAG side bear-

ing

no. 4

on the 787 engine, a distance gauge

must be temporarily installed against the inner

bearing. Slide the outer bearing until stopped by

the distance gauge, then remove it.

1. Distance gauge

TYPICAL

1. Distance gauge

2. Outer bearing

15, Distance Ring

When installing the distance ring, make sure to

position it with its chamfer toward the counter-

weight of the crankshaft.

787 Engine

13, Crankshaft Gear

Position the long flange of the gear toward the

counterweight of the crankshaft. Also, make sure

to align the gear keyway with the Woodruff key

on the crankshaft.

ENGINE DISTANCE GAUGE

717 P/N 290 876 827

787 P/N 290 876 828

F01D1WA

1

2

F01B0HA

1

F01D1YA

1

2

Loading...

Loading...