Section 05 FUEL SYSTEM

Sub-Section 02 (FUEL CIRCUIT)

05-02-9

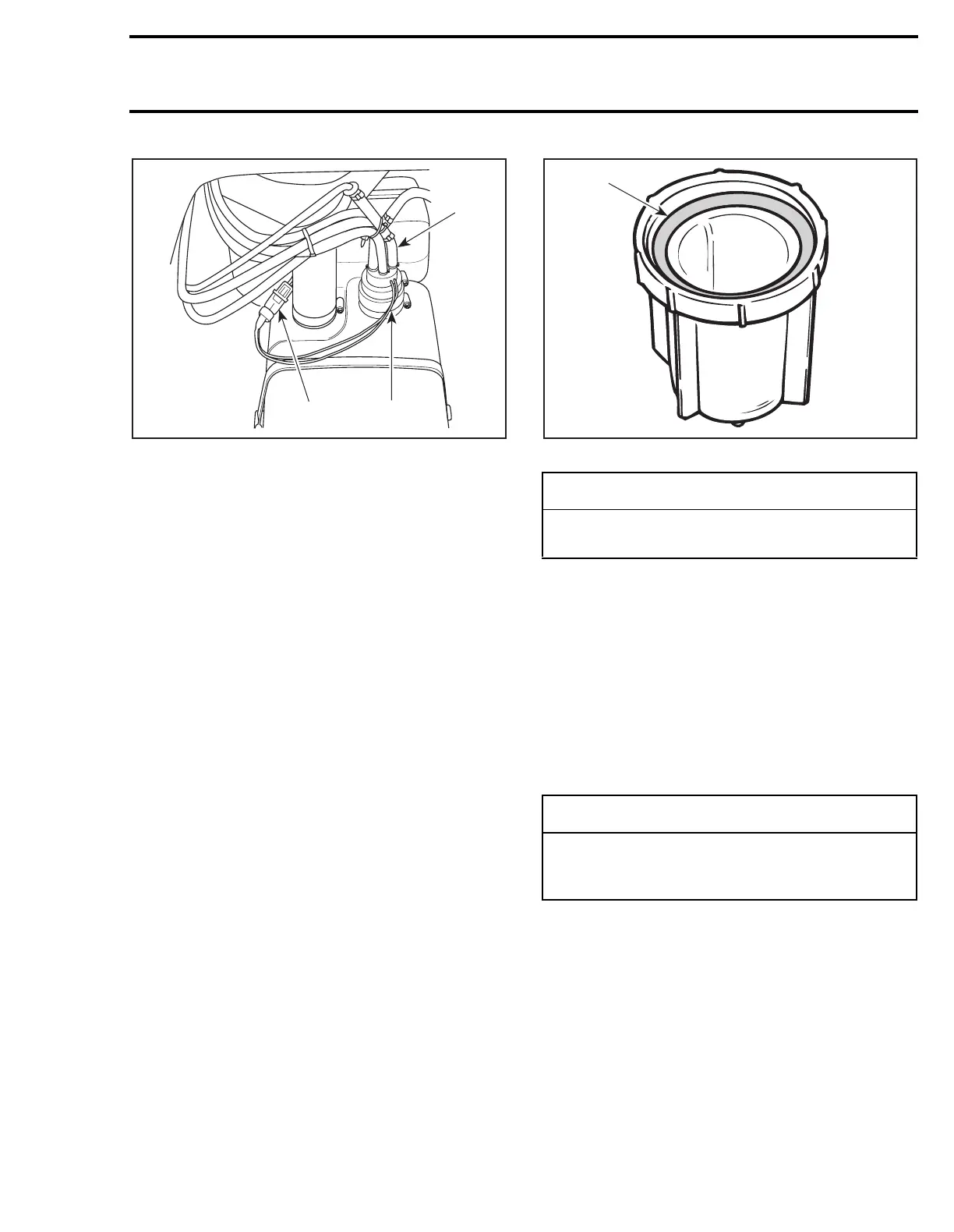

TYPICAL

1. Wiring harness

2. Baffle pick up adapter

3. Fuel hoses

Loosen lower clamp

no. 10

of baffle pick up

adapter and pull out baffle

no. 8

from fuel tank.

Remove upper clamp

no. 12

from adapter

no. 11

and slide adapter from baffle.

Push inward on the 3 clips at the base of the baf-

fle in order to remove the filter. Pry base off using

a small slotted screwdriver (if necessary).

INSPECTION

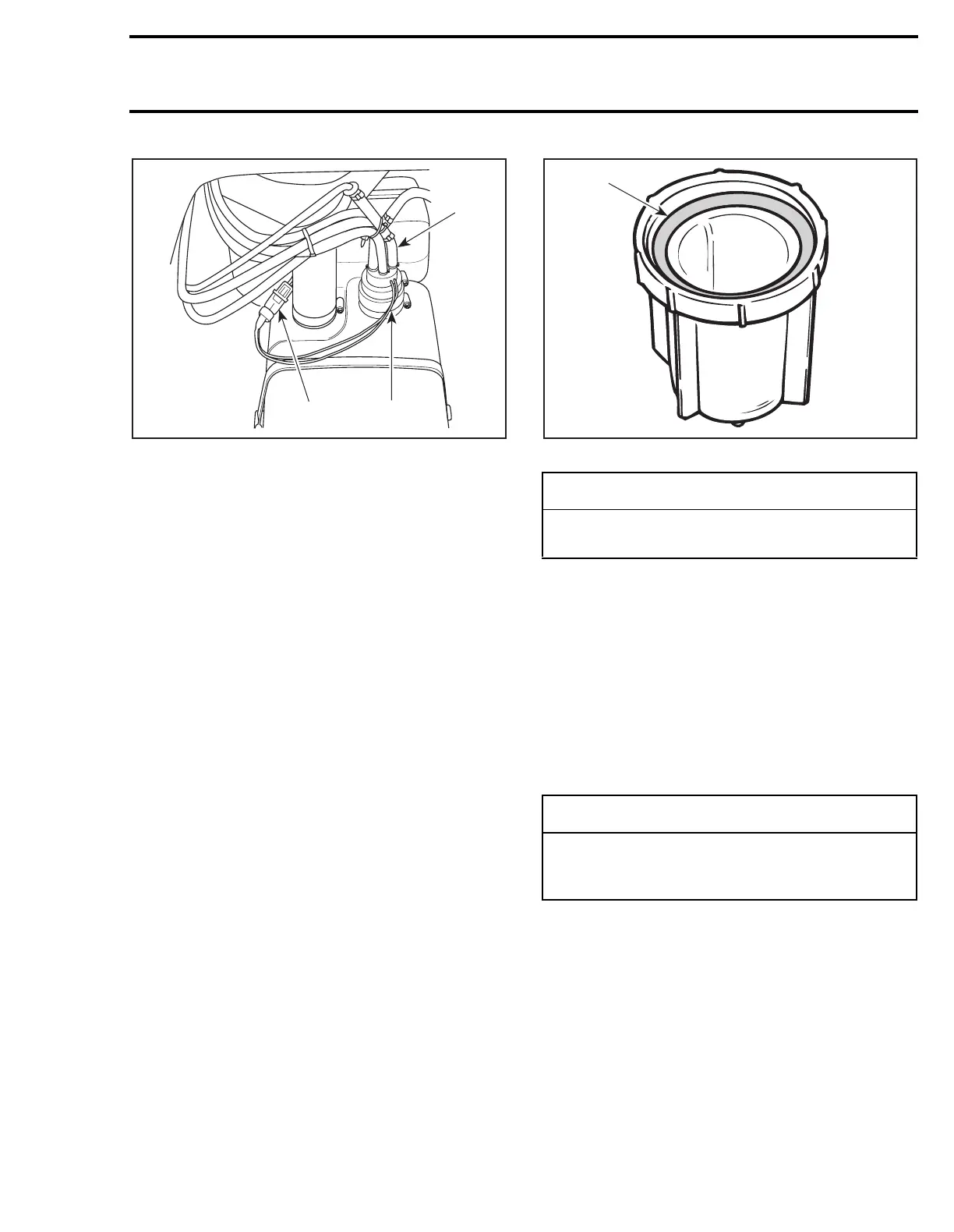

1, Fuel Filter

Inspect fuel filter condition. Carefully use low

pressure compressed air to clean fuel filter. Re-

place filter if permanently clogged or damaged.

2, Fuel Filter Bowl

Check filter bowl for water contamination.

3, Gasket

Inspect gasket condition. Make sure gasket is

well positioned into the filter bowl

no. 2

.

1. Gasket in bowl

5, Filler Neck Hose

Verify fuel filler neck hose for damage. Always en-

sure that clamps

no. 4

are well positioned and

tightened. Torque clamps to 4 N•m (35 lbf•

in

).

6, Pressure Relief Valve

This valve will eliminate fuel spillage when the

watercraft is upside down. If pressure is built up

in fuel system the valve should open at 10 kPa

(1.5 PSI) to release the pressure.

NOTE:

It is a one-way valve with an arrow to indi-

cate the air flow.

7, Check Valve

Black side of the one-way check valve is the valve

outlet. It allows air to get in reservoir.

9, Baffle Pick Up Filter

Inspect filter

no. 9

of baffle pick up. Clean or re-

place as necessary.

F01F21A

12

3

◆

WARNING

Ensure that there is no leakage from the fuel

filter.

◆

WARNING

If pressure relief valve is stuck, the pressure

in fuel system will build up and it may cause

fuel leakage in engine compartment.

F01F02A

1

Loading...

Loading...