Section 11 HULL/BODY

Sub-Section 02 (ADJUSTMENT AND REPAIR)

11-02-28

– heavy-duty polisher

– power sander

– paint brush

– plastic container (mixing)

– spray gun

– plastic squeegee

Materials

– fiberglass mat

– fiberglass cloth

– polyester resin

– cardboard

– masking tape

– sandpaper

(100-grit, 220-grit, 320-grit, 400-grit, 600-grit,

1000-grit)

– 24-grit sanding disks

– Bombardier gelcoat putty

– Bombardier liquid gelcoat

– acetone

– cabosil

– epoxy filler

– medium compound (white)

– fine compound (white)

–wax

HULL INSERT REPAIR

For hull insert repair proceed as follows:

Cut plastic hull insert flush with hull using a saw.

1. Hull

2. Plastic hull insert

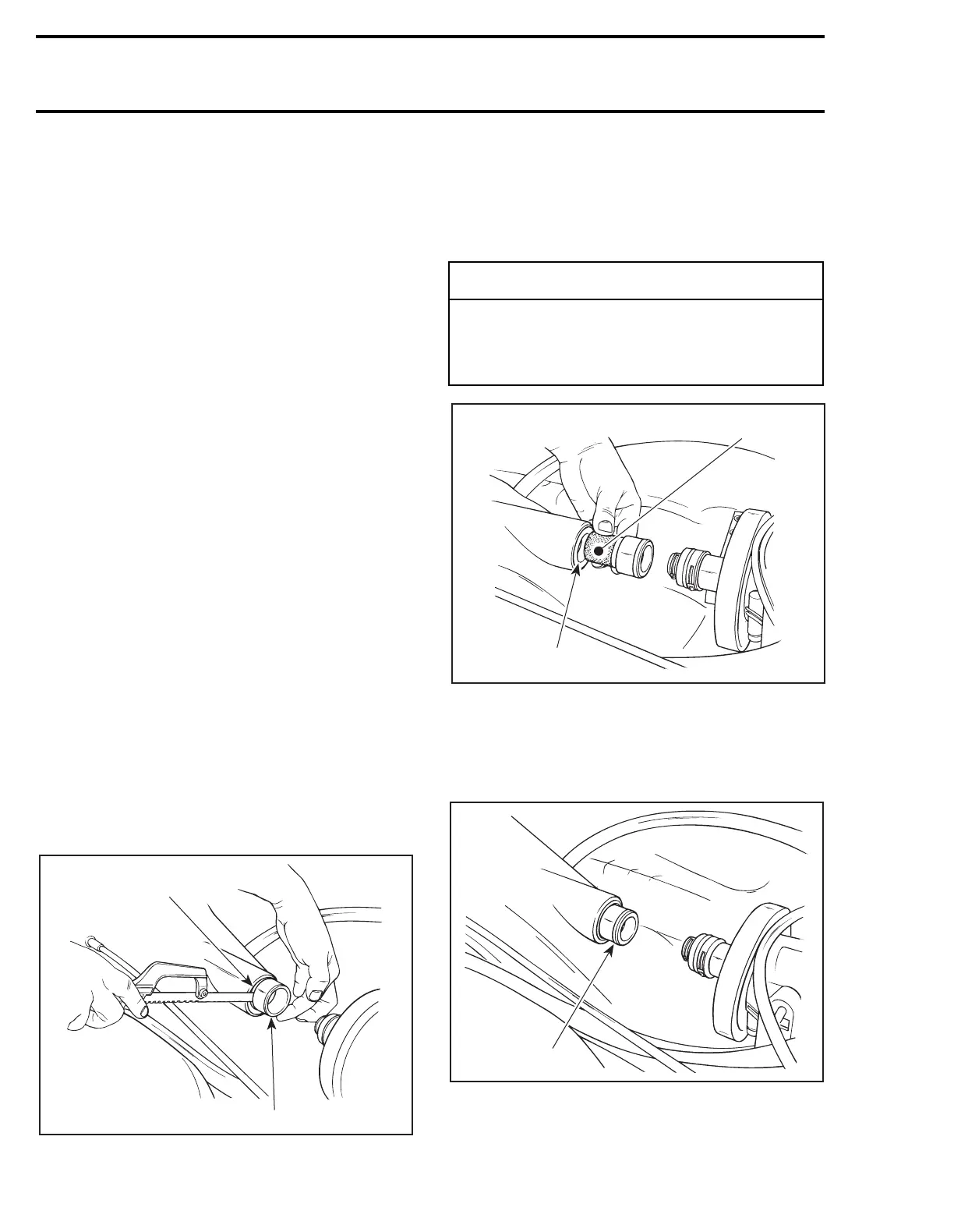

Mix epoxy glue (3M-05900), follow manufacturer

instructions.

Apply epoxy glue on aluminum insert (P/N 292

000 075) knurled surface and on plastic insert in-

ner bore.

1. Knurled surface

2. Inner bore

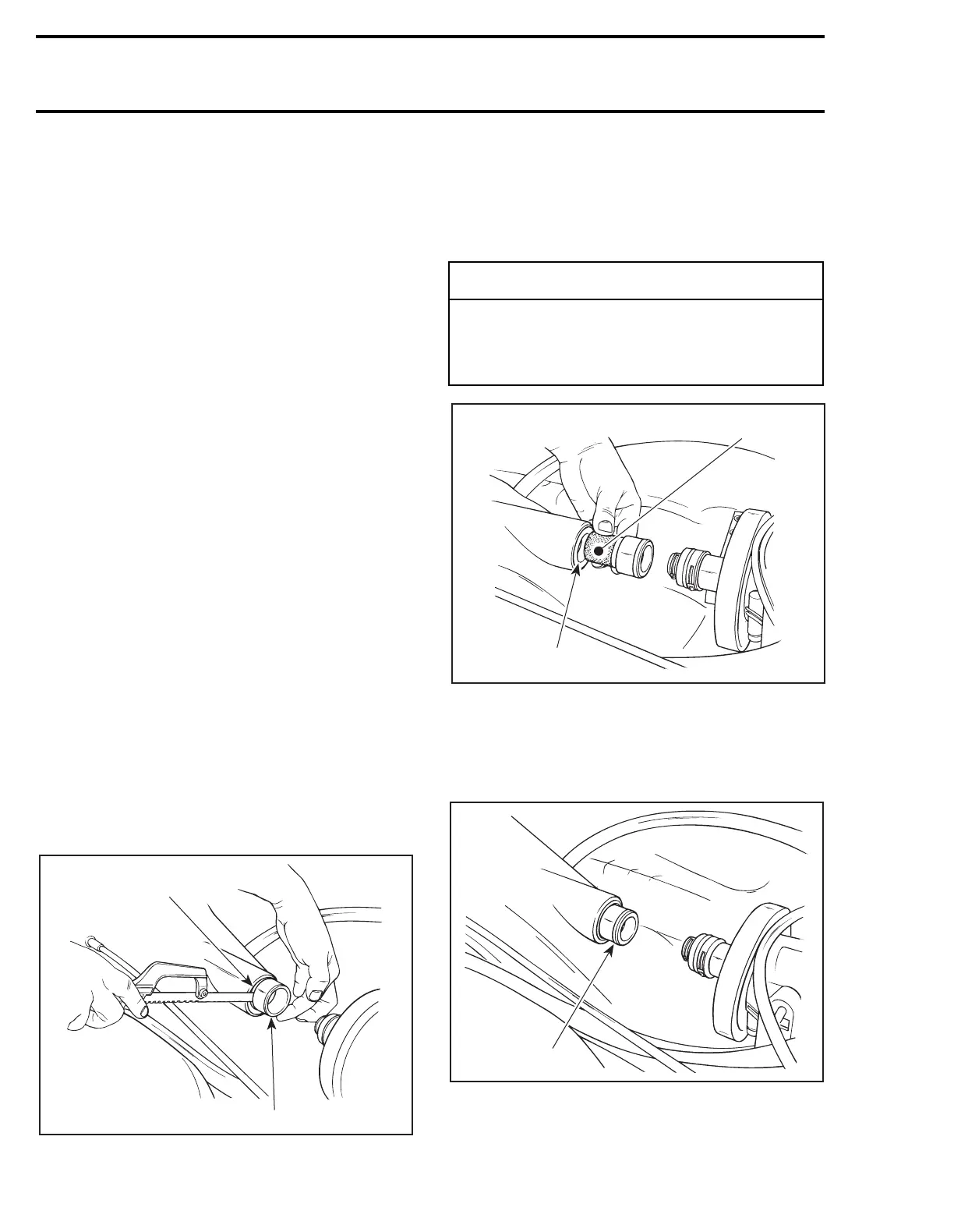

Install aluminum insert into plastic hull insert.

NOTE:

Align aluminum insert as much as possi-

ble with PTO flywheel.

1. Aluminum insert

NOTE:

The epoxy glue curing time is 30 minutes.

F01L2UA

1

2

-

CAUTION

If you notice any clearance between plastic

insert and aluminum insert, fill gap with ep-

oxy glue to obtain good adhesion of alumi-

num insert.

F01L2VA

1

2

F01L2WA

1

Loading...

Loading...