Section 03 ENGINE

Sub-Section 02 (LEAK TEST)

03-02-2

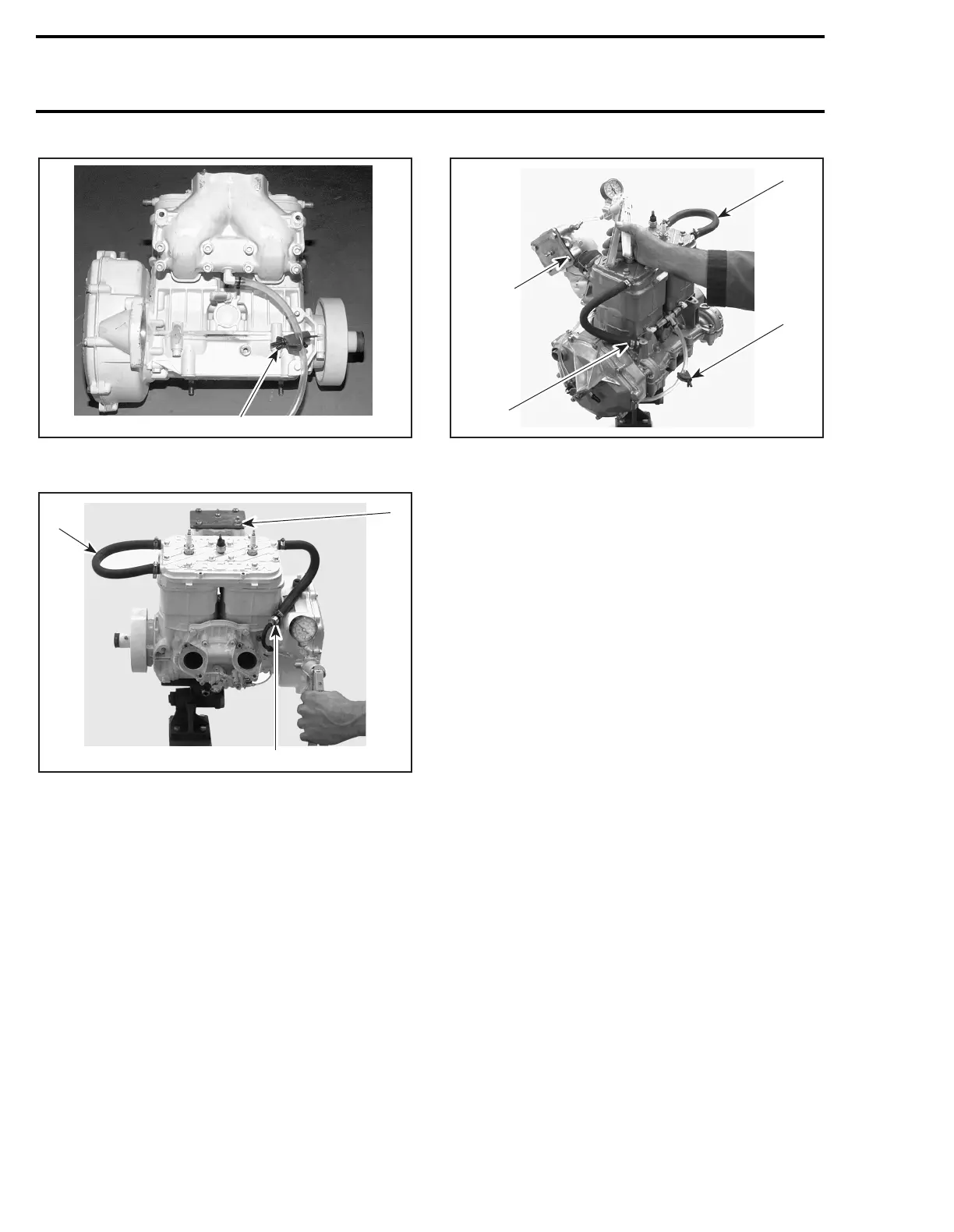

717 ENGINES — REAR VIEW

1. Engine drain hose blocked with a hose pincher

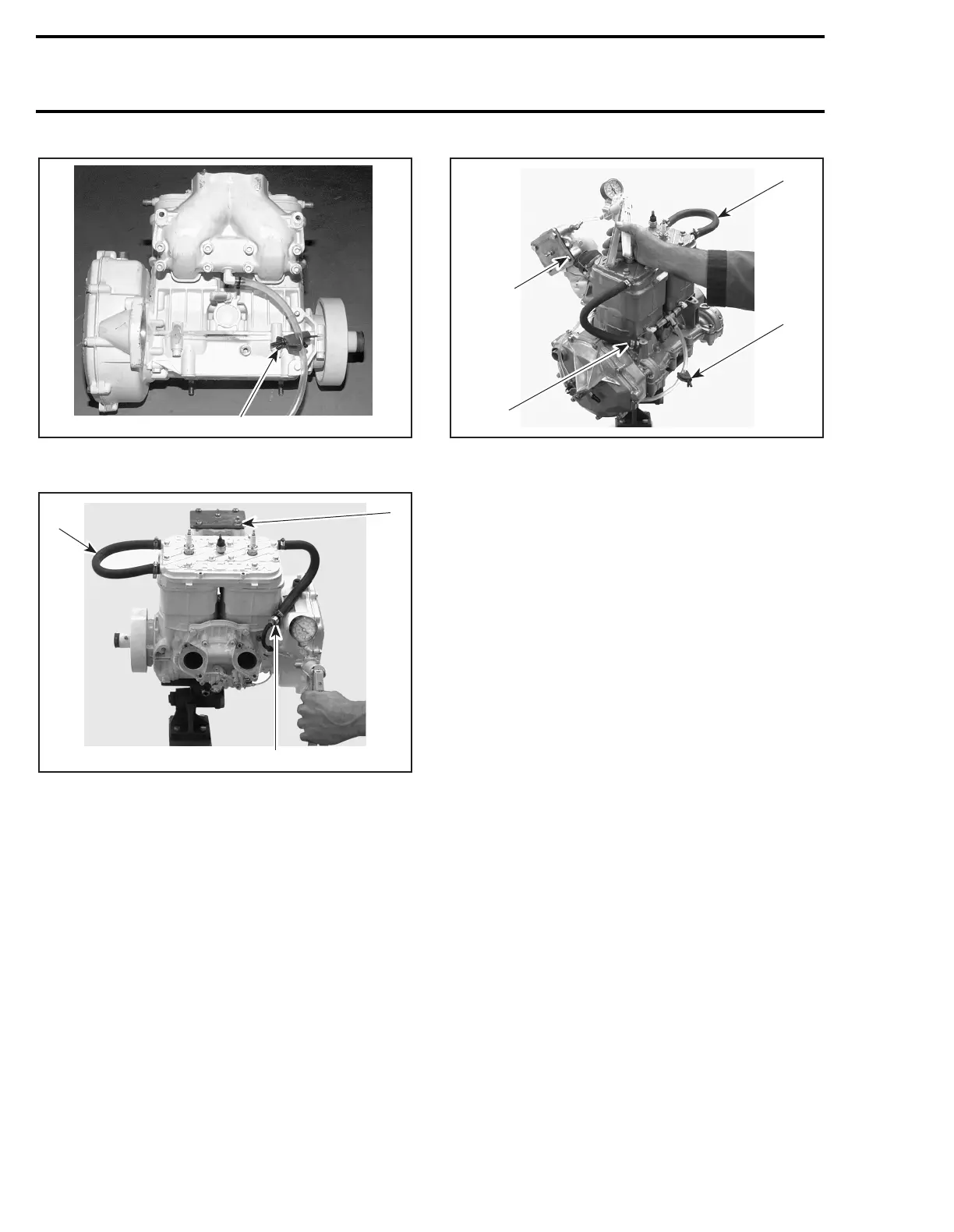

717 ENGINES — FRONT VIEW

1. Loop hose and use clamps

2. Use 2 washers with exhaust manifold stud

3. Hose with adapter and nipple

787 ENGINE

1. Loop hose and use clamps

2. Hose with clamps. Plug end with a screw

3. Block engine drain hose with a hose pincher

4. Use 2 washers with exhaust manifold stud

NOTE:

Water is not required for testing.

Activate pump and pressurize engine cooling sys-

tem to 34 kPa (5 PSI).

Wait 3 minutes and check if pressure drops; if so,

verify all testing components.

– If kit components are not leaking and pressure

drops, verify all external jointed surfaces, tem-

perature sensor and the O-ring between the

spark plug area and the engine cylinder head

cover. If none of these components are leaking,

there is an internal leak and it can be detected

with Bottom End and Top End testing.

Bottom End and Top End

Remove the carburetor(s) and gasket(s). Make

sure the surface of the intake manifold (717 en-

gines) or rotary valve cover (787 engine) are clean.

NOTE:

With the BN-38 carburetor, intake mani-

fold must be removed first to withdraw carbure-

tor; Then, reinstall intake manifold to proceed

with testing.

Install the intake plate(s)

no. 3

with fasteners

from the kit and tighten adequately.

On engines with the RAVE system, remove the

RAVE valves and gaskets.

F01B2UB

1

F01B2VA

2

3

1

F01B2WA

1

3

2

4

Loading...

Loading...