151

6.7.4. Electronic gear

Users could set different electronic gear ratios to enable the mechanism to move different distances.

Relevant parameters are presented below.

Electronic gear numerator

Electronic gear denominator

Electronic gear numerator 2

Electronic gear numerator 3

Electronic gear numerator 4

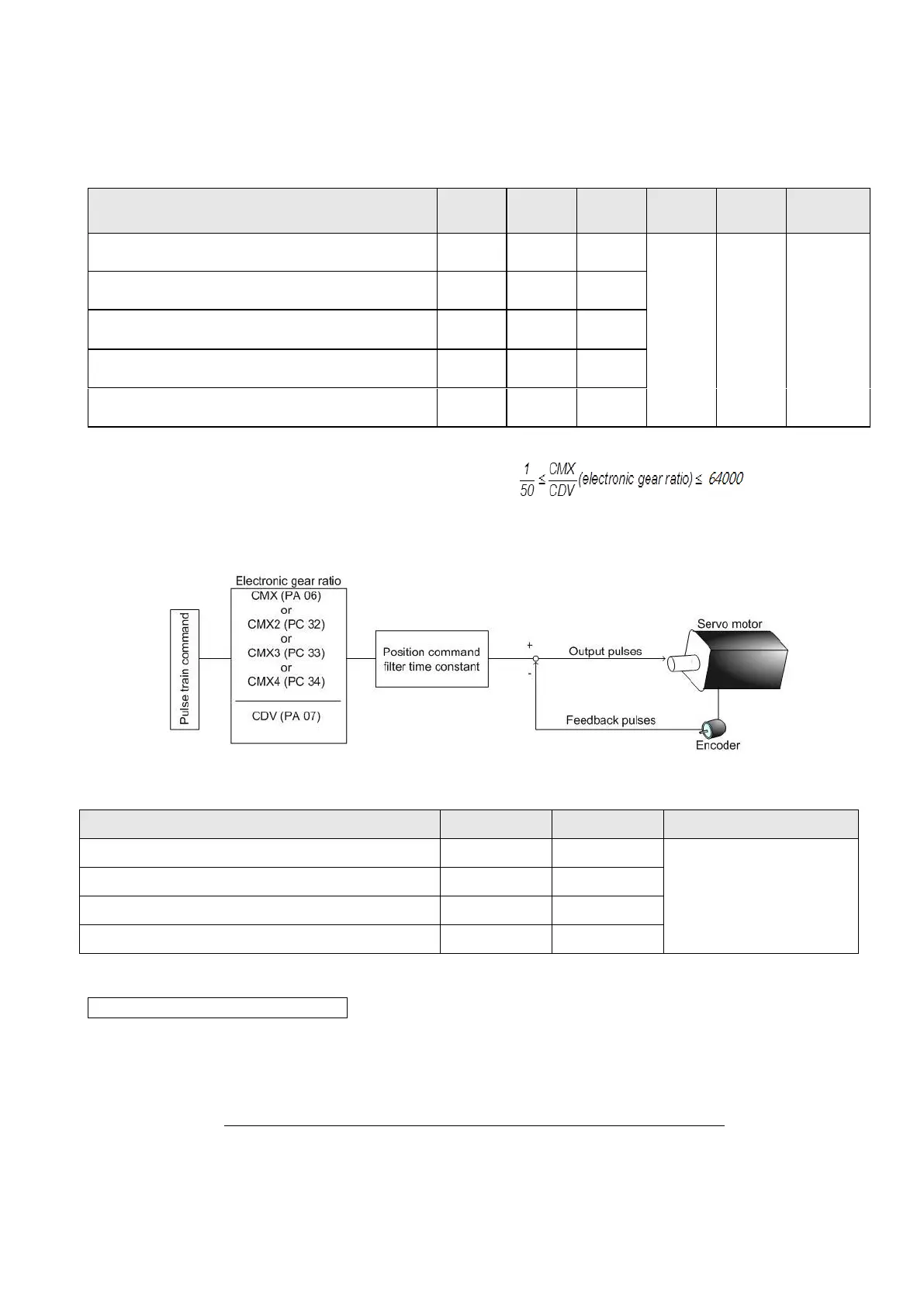

The improper setting could lead to unexpected fast rotation so make sure to set them in the state

of SERVO OFF. The range of the electronic gear ratio is . If the setting

value is outside this range, the operation of motor may not be performed. The relationship of electronic

gear numerator and electronic gear denominator is plotted below.

4 electronic gear numerators are available for users to select. Enable the function CM1 and CM2 of DI

to switch. See the table below.

Electronic gear numerator (PA06)

Electronic gear numerator 2 (PC32)

Electronic gear numerator 3 (PC33)

Electronic gear numerator 4 (PC34)

Note: 0: OFF (CMx-SG is open-circuit), 1:ON (CMx-SG is short-circuit), x=1,2

Calculation of electronic gear ratio

Before calculating this value, users have to know the specifications the motor encoder resolution

(2

22

=4194304ppr), the reduction rate, gear ratio of machine. Use the following equation to calculate the

electronic gear ratio.

Encoder resolution 4

Electronic gear ratio=

Load distance per revolutio(angle) / Distance pulses to be shifted entered by user

Loading...

Loading...