224

11.5. Inspection and maintenance

11.5.1. Basic inspection

It is recommended for users to inspect the following items periodically.

(1) Inspect for loosen screws of the drive, terminals and the connection to mechanical system. Tighten

any loosen screws carefully.

(2) Check servo motor bearings, brake section, etc. for unusual noise.

(3) Avoid any naked wires or damaged, broken wires applied for the servo motor.

(4) Check that all wiring terminals are correctly insulated.

(5) Check for dust accumulation on the servo drives.

(6) Check the servo motor shaft and coupling for connection

11.5.2. Maintenance

Users should not disassemble the servo drive or motor as maintenance performing.

(1) Periodically clean the surface of servo drive and motor.

(2) Operate the servo drive and motor within the specified environmental condition range.

(3) Clean off any dust and dirt that accumulated on the ventilation holes of servo drive.

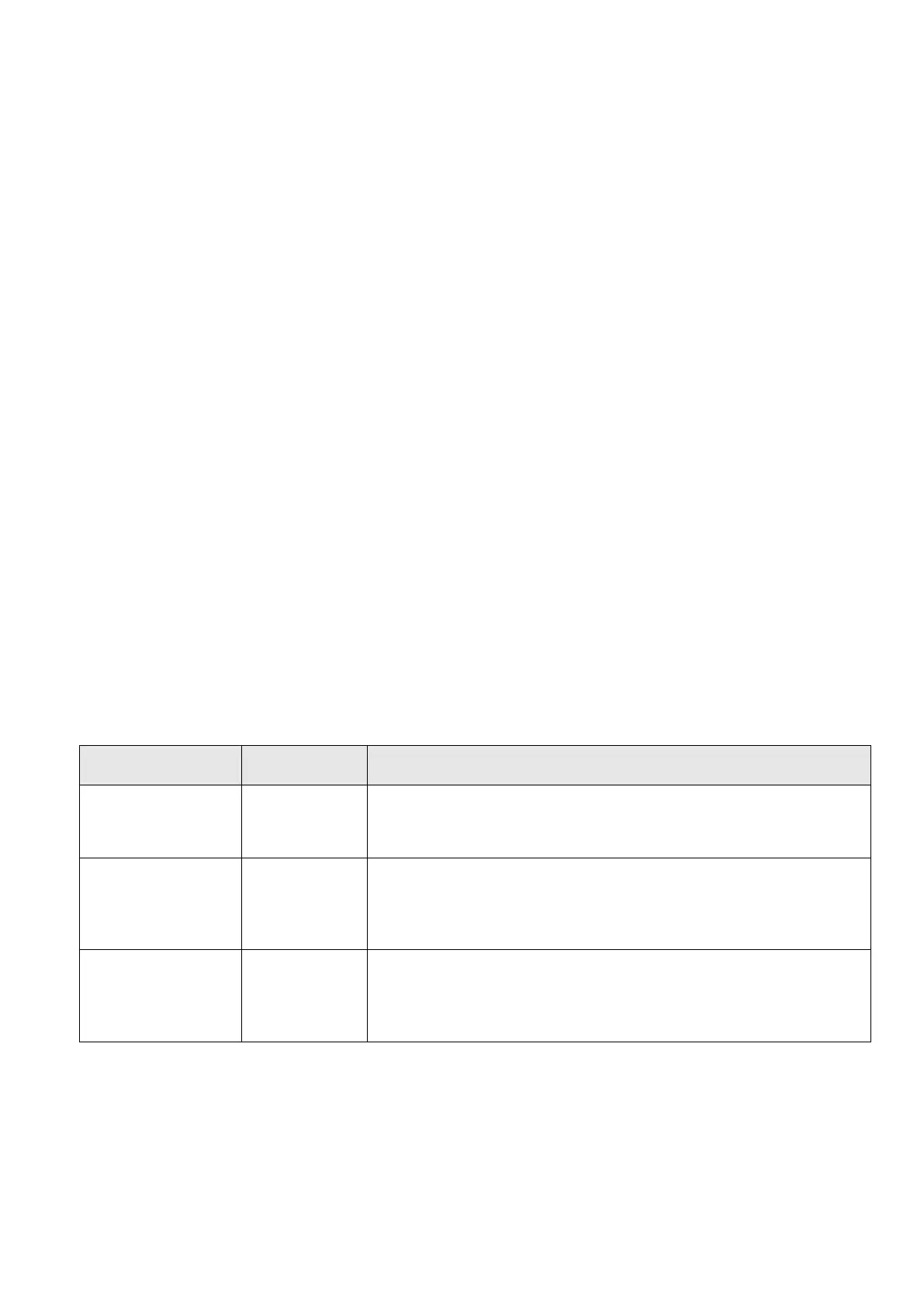

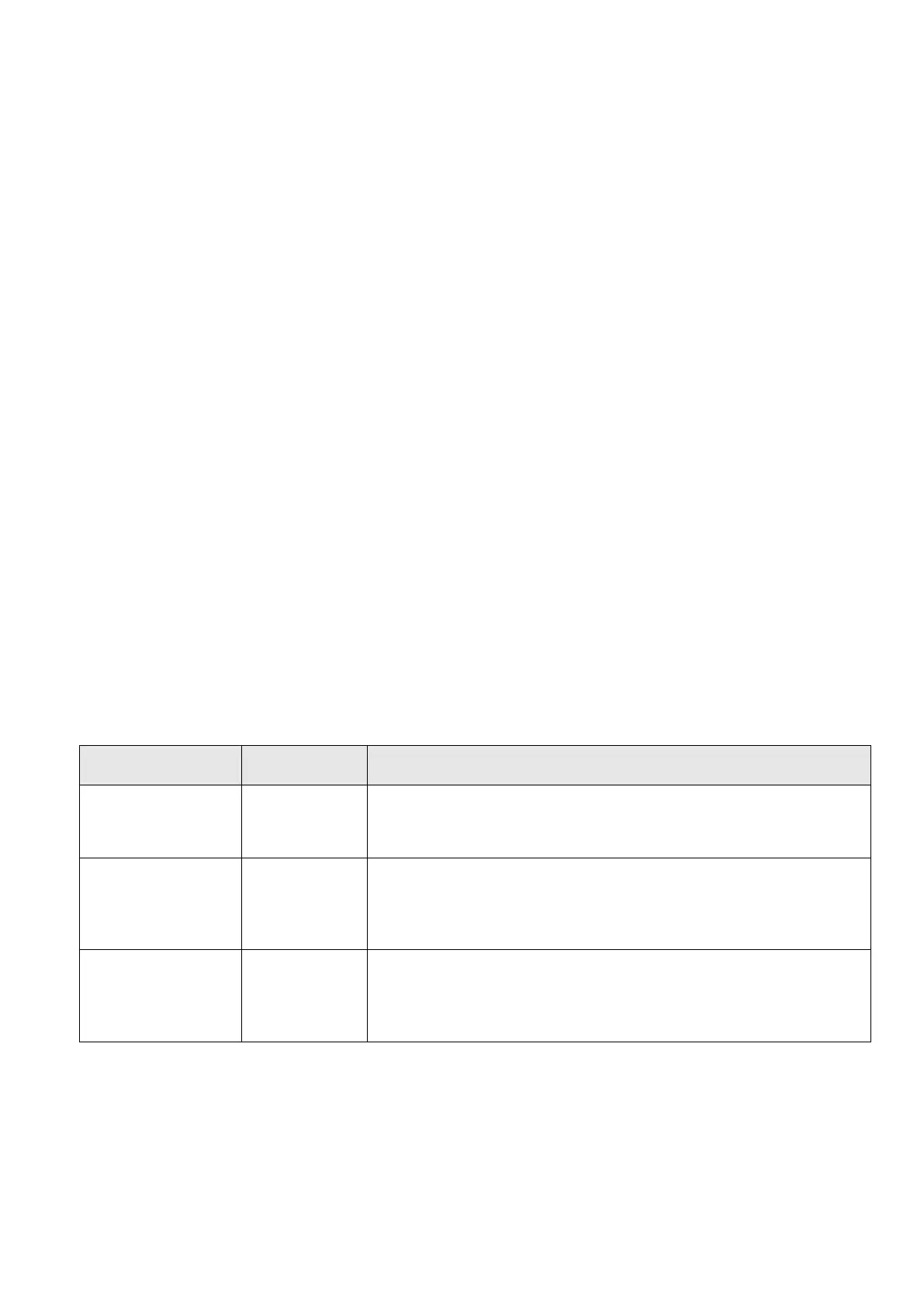

11.5.3. Life of consumable components

Some components inside servo drive are consumable and must be replaced periodically. The life of

consumable components is varied, which depend on operating methods and environmental conditions.

For parts replacement, please contact your sales. The lives of particular components are listed below.

The power supply capacity of relay decides the relay‟s lives. The

accumulated switch times are 100,000 times.

The cooling fan bearings reach the end of their life in 10,000 to 30,000

hours. It should be replaced if noise is found during inspection.

Affected by ripple currents and deteriorates in characteristic. Its life

greatly depends on surrounding air temperature and operating

conditions. The capacitor will reach the end of its life in 10 years of

continuous operation in normal air-conditioned environment.

Loading...

Loading...