191

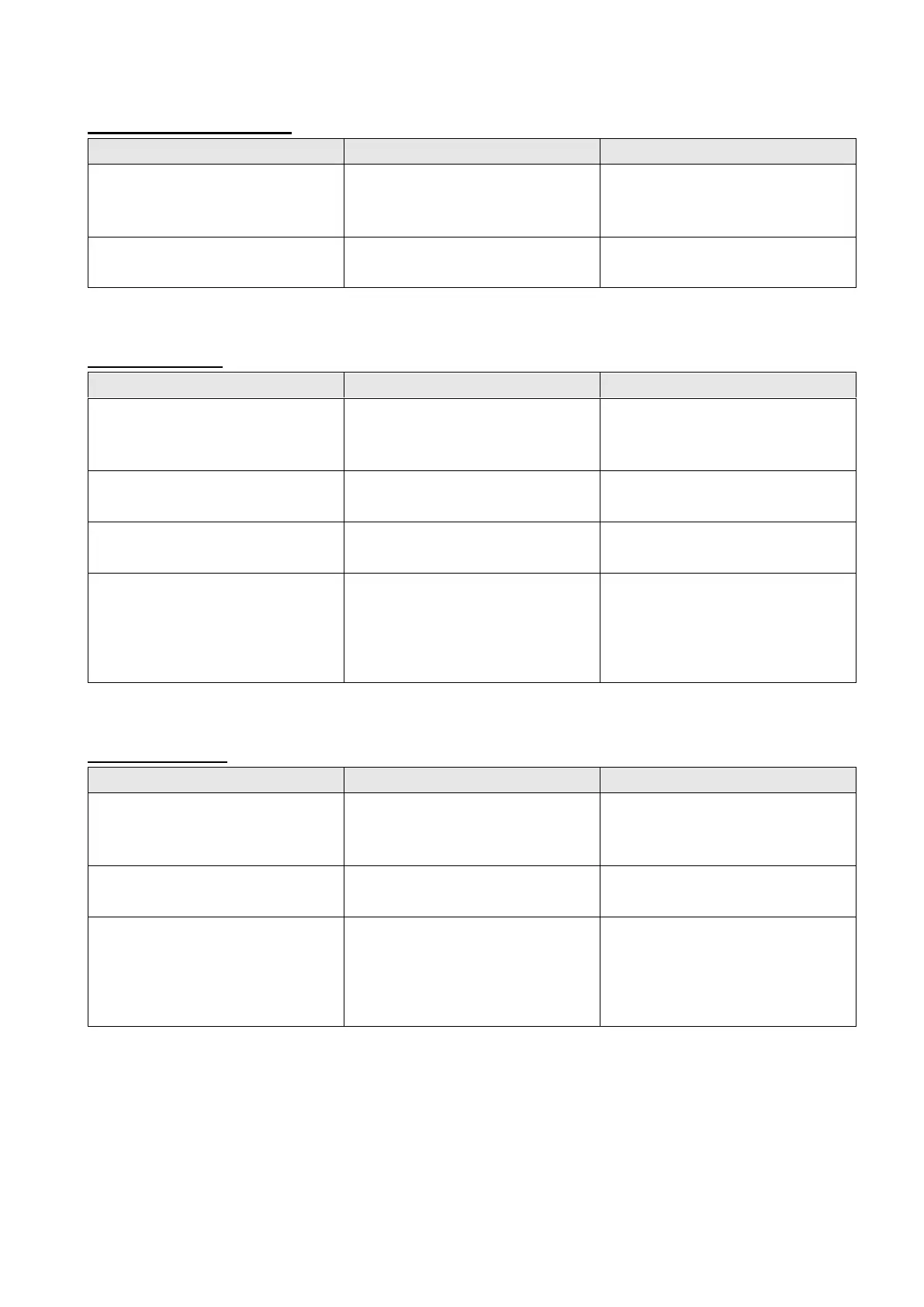

AL04 Regenerative alarm

Set PC36 to be 0 and re-power on,

if AL04 is occurred soon, it means

the brake transistor broken.

Contact agent for proper service.

Built-in brake resistor or brake

option is disconnected.

AL05 Overload 1

Operate the servo drive in heavy

duty continually.

Check if mechanism load is huge.

Upgrade the capability of servo or

reduce the duty.

Improper gain values setting.

Check if vibration of mechanism is

occurred.

Re-operate the auto-gain tuning job

to obtain the proper gain value.

Servo system is instable.

Check if acceleration/deceleration

time constant is proper.

Extend these setting values.

As motor shaft is rotated slowly with

Servo OFF, the pulses feedback

should vary in proportion to rotary

angle. If the indication skips or

returns midway, it is faulty.

Contact agent for proper service.

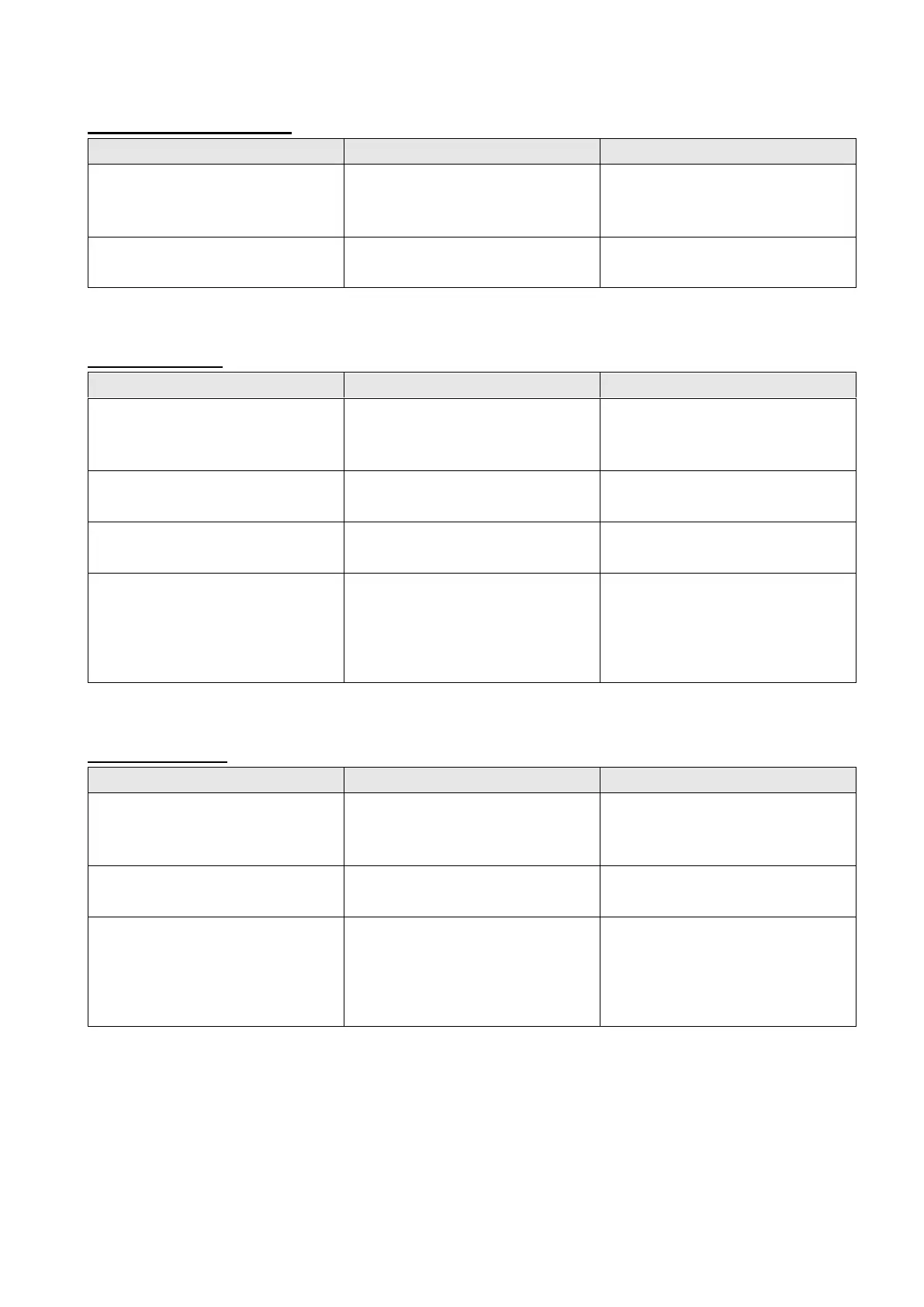

AL06 Over speed

Command pulses frequency

exceeded the permissible

instantaneous speed frequency.

Check the frequency of command

pulses whether exceeds the

permissible range.

Set the command pulses frequency

correctly.

Improper acceleration/deceleration

time constant settings.

Check if these values are too small.

Increase acceleration/deceleration

time constant.

Servo system is instable to cause

overshoot.

Observe if the mechanism is with

vibration.

1. Re-set proper servo gain value.

2. If gain could not be set to proper:

1) Reduce load inertia ratio; or

2) Set acceleration/deceleration

time constant to proper value.

Loading...

Loading...