Section 10: PRS Alpha Control Box Wiring • May 2, 2016

© Copyright 2016 ShopBot Tools, Inc. page 10-8

Thread the proximity switch into the hole until it rests on the target.

Back it out 1 to 2 turns so there is a 1/32” – 1/16” (1-2mm) gap

between them.

Loosely thread the 1/2” nuts onto the proximity switch so that the

end plate is “sandwiched” between the two nuts.

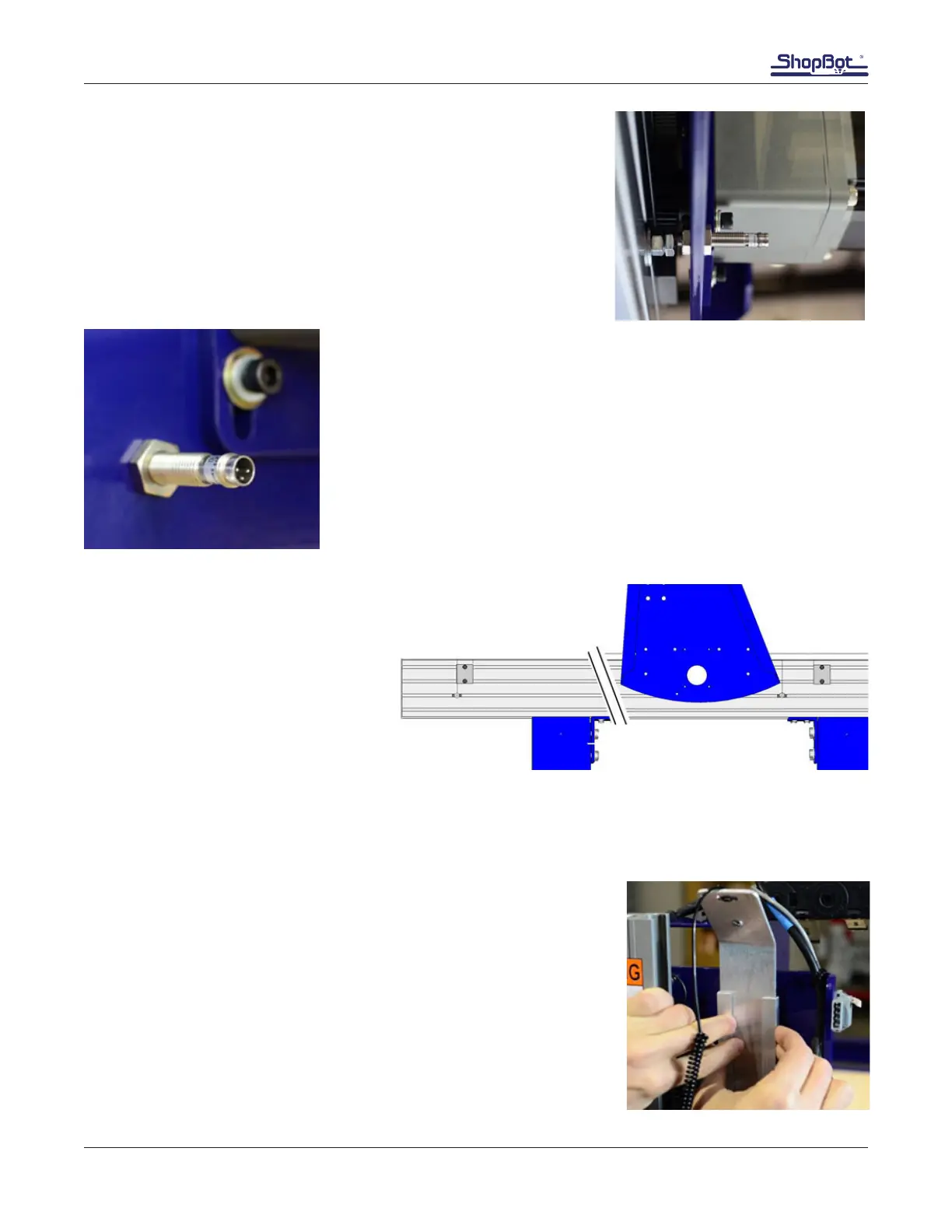

This image shows the X proximity switch from slightly below. The X1

motor is in the background.

Rotate bolt so the three prongs are oriented as shown in the image at

left. This ensures the cable will route cleanly.

Make sure the switch to target clearance is still 1/32” – 1/16” (1-2mm),

and snug both nuts with a 1/2” wrench.

Set Stop Block Positions

Ensure stop blocks are loosened.

Move gantry to one end of rail, and

back off gantry to access stop blocks.

Tighten stop block screws securely,

ensuring stop blocks do not move

during tightening.

Repeat process at other end of rail.

Check Y-Axis Proximity Switches

Run YZ car to the complete right and ensure proximity switch is triggered.

Repeat for left side.

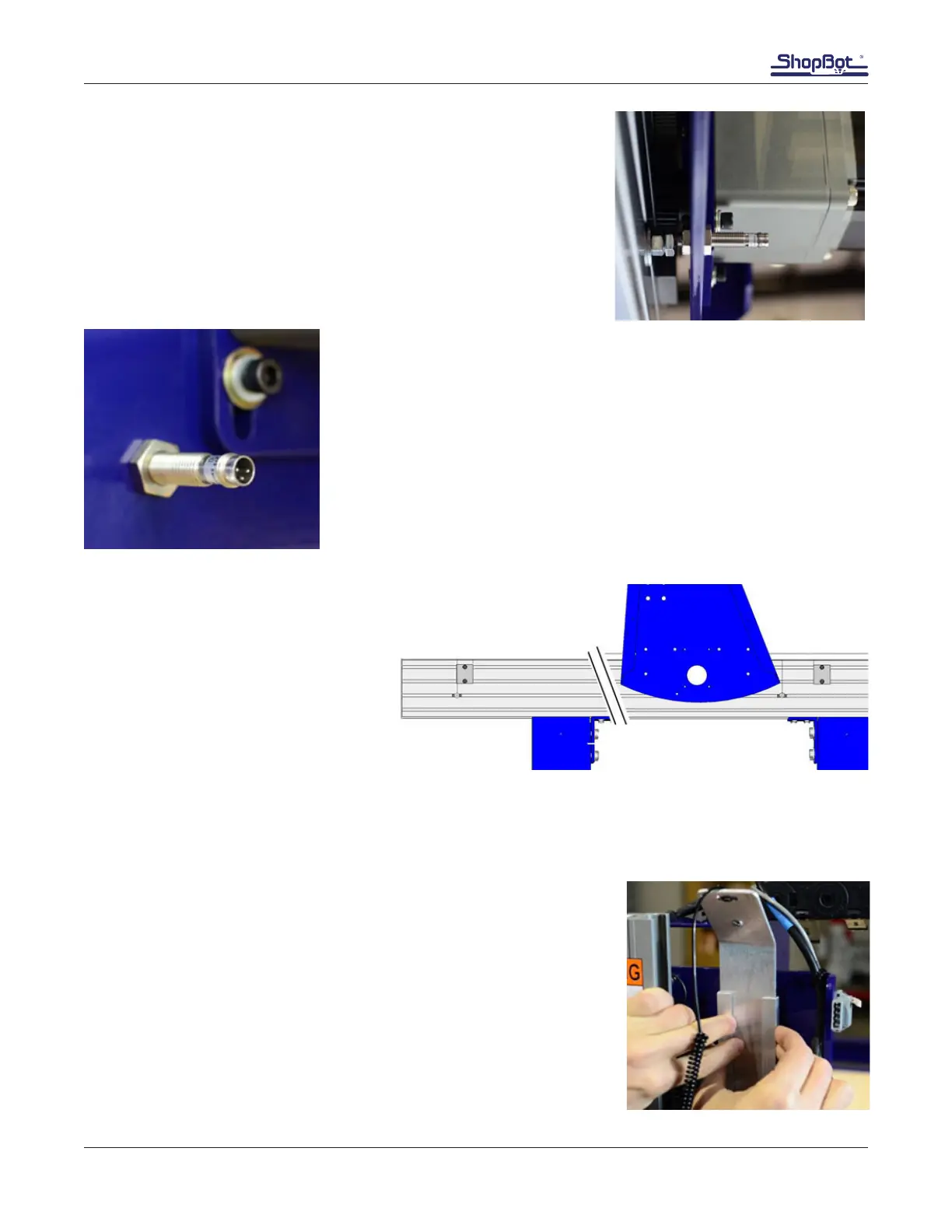

Mount Z Zero Plate Assembly

Sandwich the Z plate between the two U channel brackets with the

VHB tape facing opposite from the upturned Z plate ange.

Center Z plate between Z rail and the YZ plate ange. Position

brackets 1” down from top of YZ plate. Remove backing tape from

VHB tape and press the brackets onto the YZ plate.

Loading...

Loading...