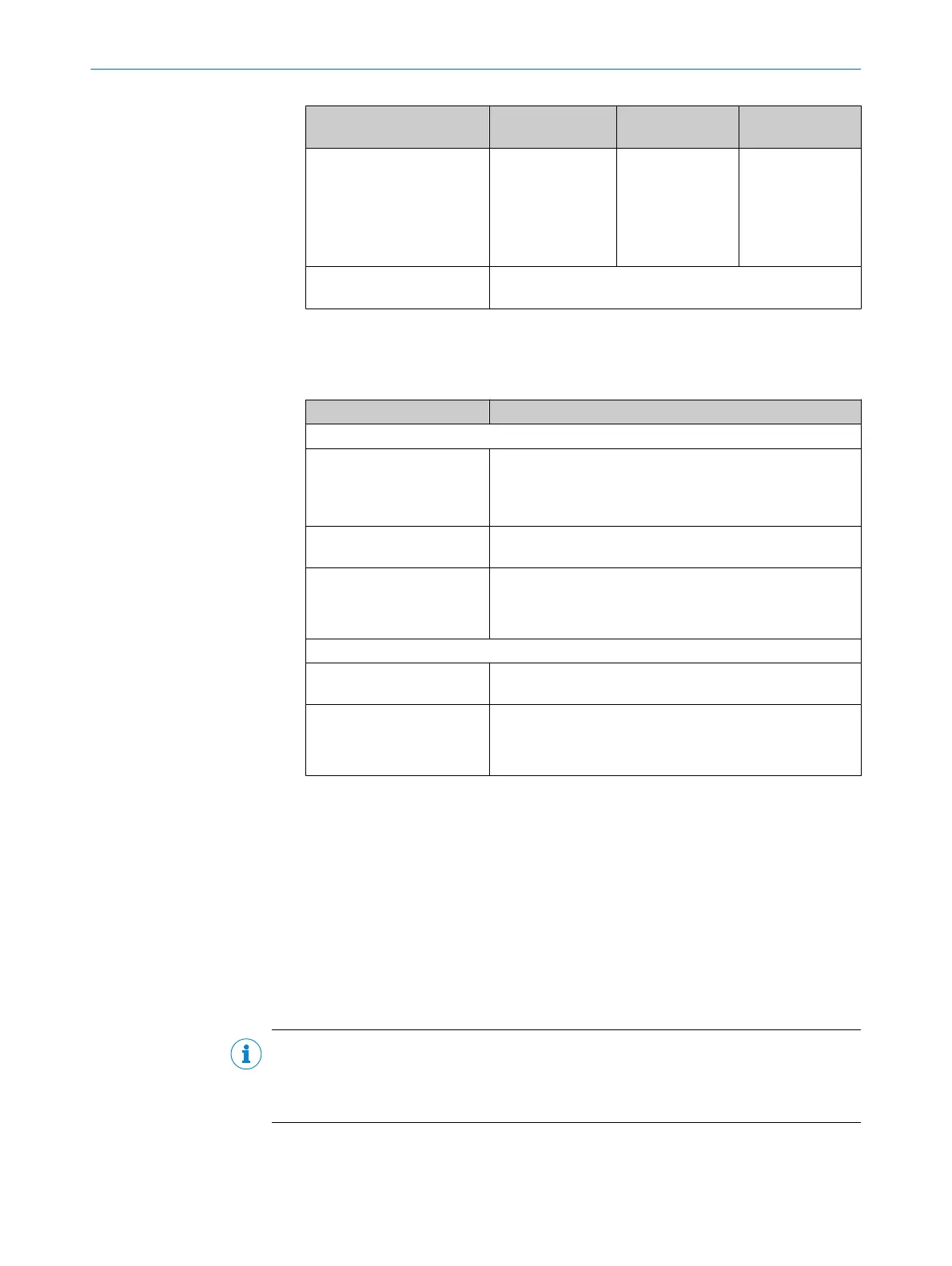

Field Input assembly

instanc

e

Output assembly

instance

Size (in 8-bit

words)

Safety output (from the view

of t

he control)

1278 Dependent on

assembly used:

•

100

OR

•

103

Dependent on

assembly used:

•

Assembly 100:

8

•

Assembly 103:

16

Configuration assembly

ins

tance

1278

6. Define the connection as a unicast connection over EtherNet/IP or as a multicast

connec

tion over EtherNet/IP.

7. Set the parameters for safety.

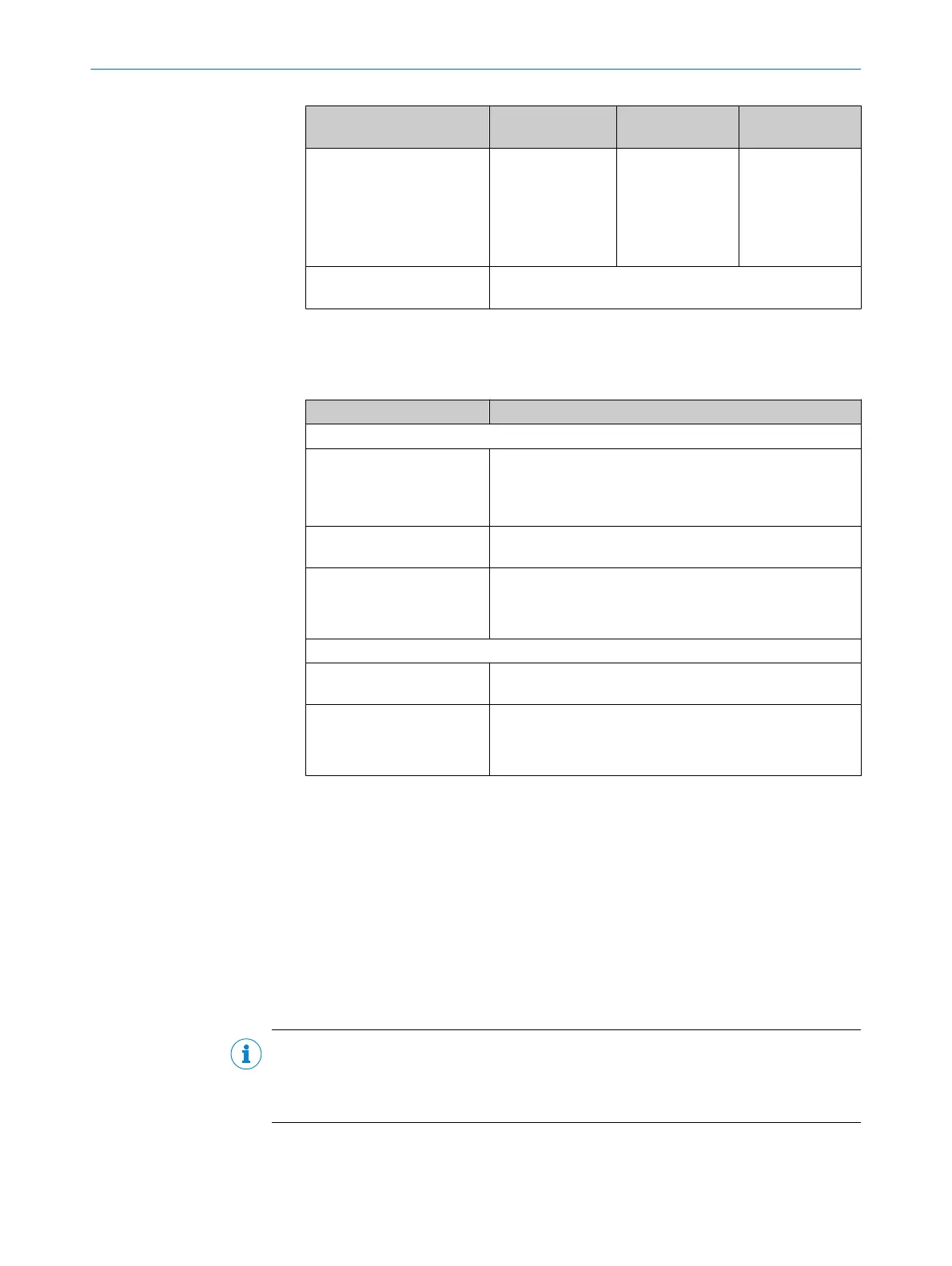

Table 8: Safety parameters

Field Value

Input (from the view of the controller)

1)

Requested Packet Interval

(R

PI)

5ms (or a multiple of this)

(Useful in many cases: 10ms. Smaller values make net‐

work transmission more prone to errors. Larger values lead

to longer response times.)

Timeout multiplier Depending on the network, the required response times

and t

he required availability

Network delay multiplier Dependent on the complexity of the network:

•

Simple networks can do with lower values

•

Complex networks require higher values

Output (from the view of the controller)

2)

Timeout multiplier Depending on the network, the required response times

and t

he required availability

Network delay multiplier Dependent on the complexity of the network:

•

Simple networks can do with lower values

•

Complex networks require higher values

1)

These values affect the response time of the entire safety function.

2)

These values affect the time needed to switch monitoring cases.

8. If it has not yet been done: configure, test and verify the safety laser scanner, see

"C

onfiguration", page 59.

9. Check configuration of the safety laser scanner.

10. If necessary, activate the test of the configuration signature. Copy values from

Safety Designer, EtherNet/IP overview dialog box. The controller then checks that the

configuration of the safety laser scanner remains unchanged.

11. Configure the controller as usual. Then transmit the configuration to the controller

(download).

Complementary information

NOTE

Depending on the configuration software of the controller, you can assign your own

alias names (tag names) and descriptions for the data areas (controller tags). This

facilitates the use of inputs and outputs in the logic.

Some deviating information is required for the use of non-safety-related Assembly 120.

PROJECT PLANNING 4

8027909/2023-02-22 | SICK O P E R A T I N G I N S T R U C T I O N S | nanoScan3 – EtherNet/IP™

47

Subject to change without notice

Loading...

Loading...