3 SYSTEM DESCRIPTION

TRANSLATION OF THE ORIGINAL OPERATING INSTRUCTIONS| VMS6200

Subject to change without notice

3.3.2 Recording of measured values and data processing

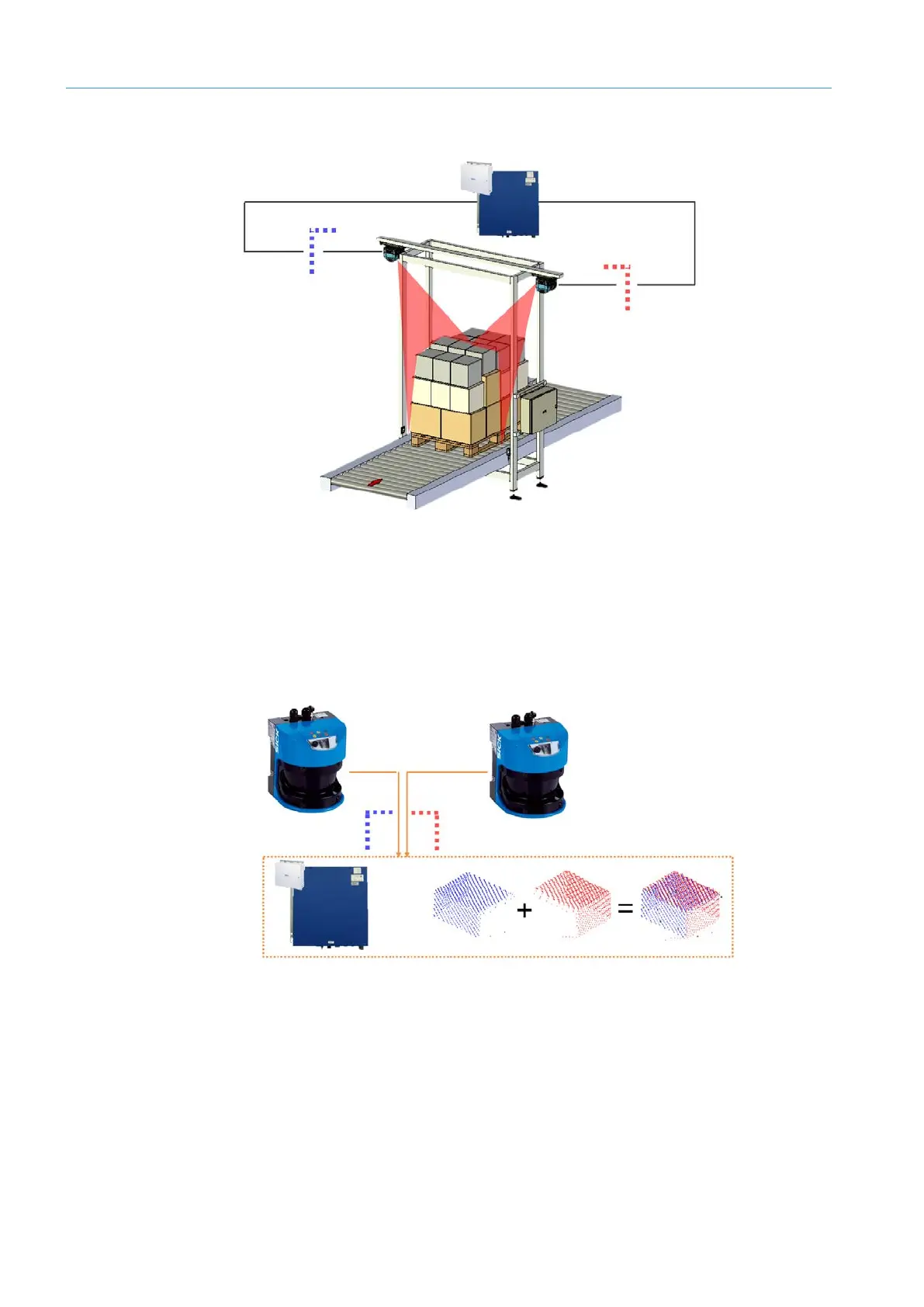

Fig. 10: Measuring point determination of the VMS6200

• The measurement process is activated via the trigger signal.

• The volume measurement devices span a two-dimensional measuring range and scan

the surfaces of the object located within this range on the conveying equipment,

without making contact.

• The volume measurement devices transmit the acquired measuring points to the

VMC800 volume measurement controller.

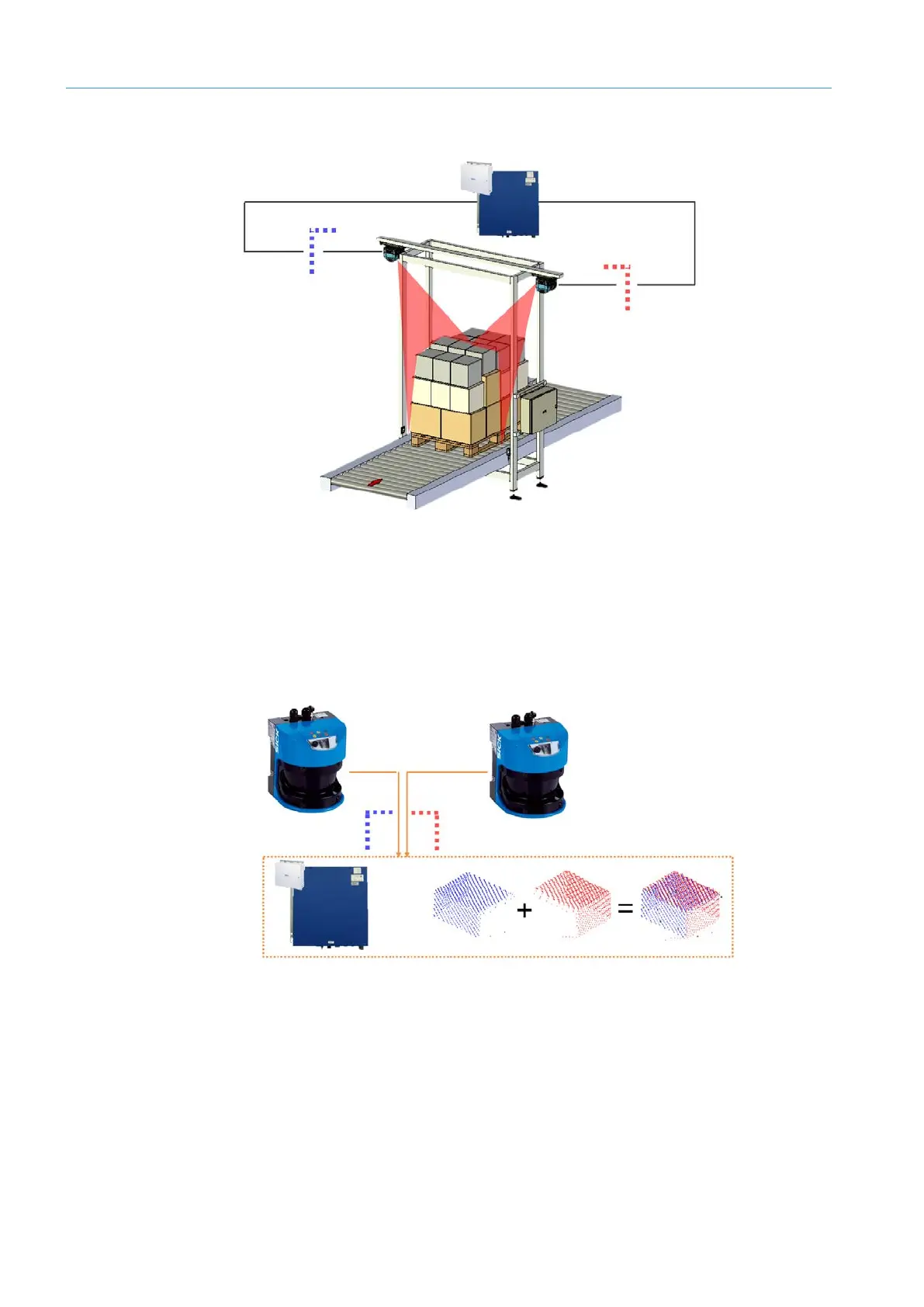

Fig. 11: 3D model generation in the VMC800 volume measurement controller

• There, a spatial model is created taking into consideration the detected conveyor

speed and the specific position of the object on the conveying equipment.

• The VMC800 calculates the volume of the smallest rectangular box that fully encloses

the object and uses this to derive the length, width and height.

• The rotation and position of the object on the conveying equipment is also determined.

• The measurement results are transmitted to the MSC800 system controller for further

processing.

Loading...

Loading...