7 MAINTENANCE AND REPAIR

TRANSLATION OF THE ORIGINAL OPERATING INSTRUCTIONS| VMS6200

Subject to change without notice

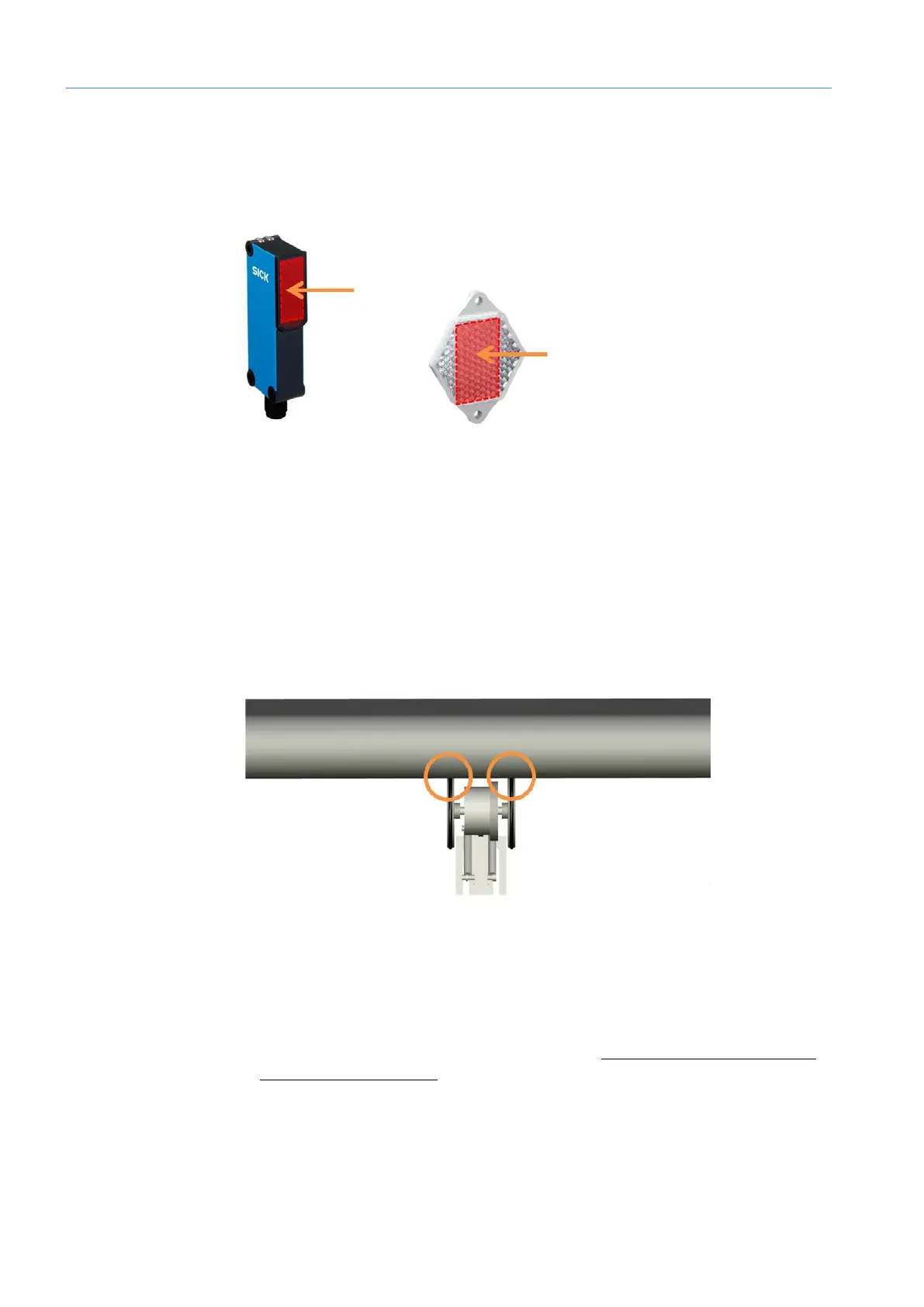

7.1.4 Cleaning the photoelectric retro-reflective sensor

Contamination on the photoelectric retro-reflective sensor can cause faulty switching

behavior.

▸

Remove any contamination from the optically active surfaces.

Fig. 38: Cleaning the optical surfaces of the photoelectric retro-reflective sensor

▸

Check that the photoelectric sensor and reflector are aligned correctly at regular

intervals.

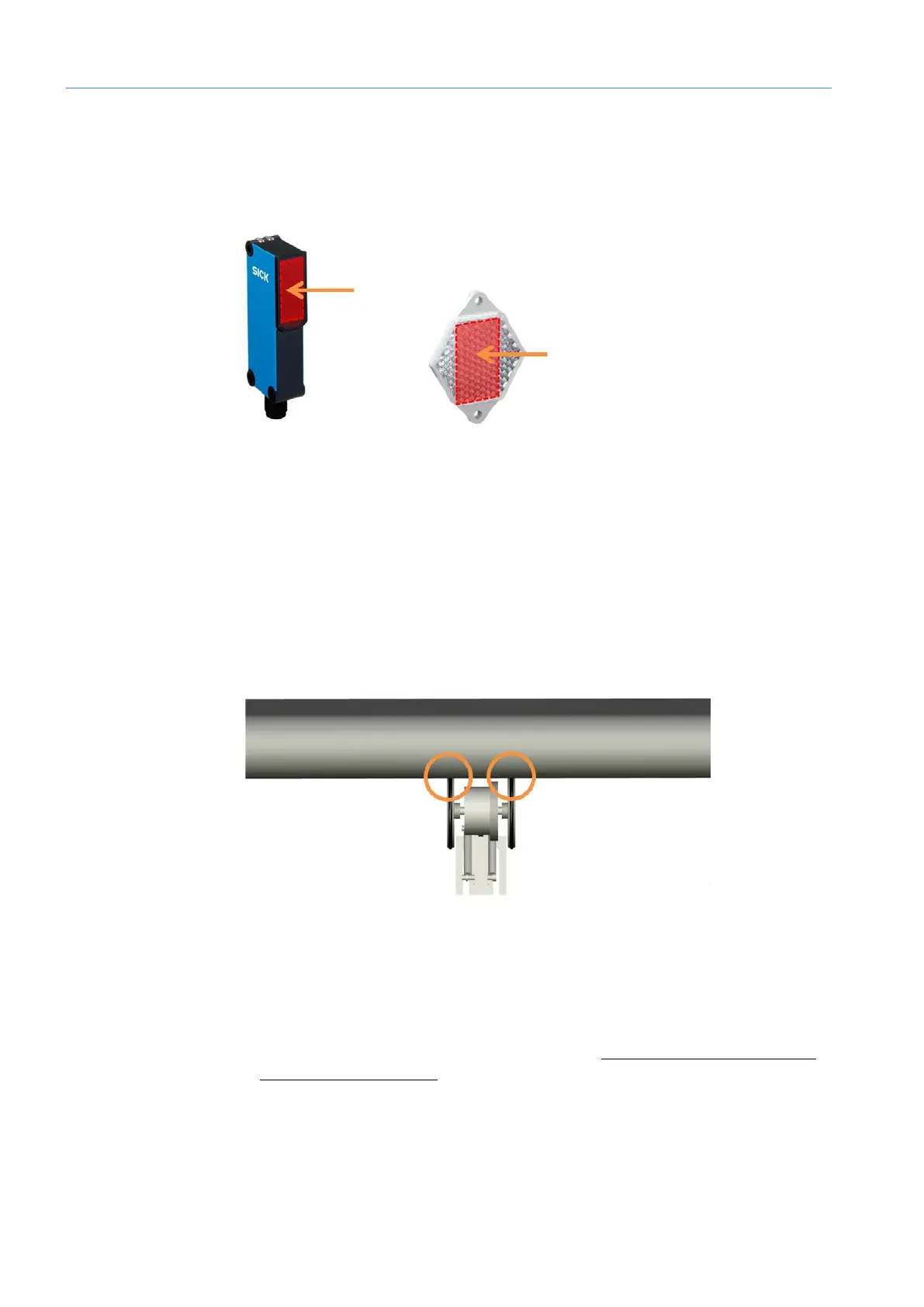

7.1.5 Cleaning the components of the incremental encoder

The measuring wheel of the incremental encoder must remain in direct and steady

contact with the conveying equipment and must turn without any slipping.

Contamination on the measuring wheel or damaged rubber rings can cause faulty

behavior of the incremental encoder.

Fig. 39: Visual inspection of the incremental encoder

▸

Remove any contamination on the measuring wheel of the incremental encoder.

▸

Replace damaged rubber rings.

▸

Check the wear of the measuring wheel.

NOTE! If it is so badly worn that contact with the conveying equipment is impaired, the

incremental encoder must be replaced (see Section 7.2.6 Replacing the components

of the incremental encoder).

Maintenance

Loading...

Loading...