MAINTENANCE AND REPAIR 7

Subject to change without notice

TRANSLATION OF THE ORIGINAL OPERATING INSTRUCTIONS| VMS6200

7 Maintenance and repair

Maintenance and repair measures may only be carried out by qualified persons.

• Qualified persons have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations and standards, to be able to perform work

assigned to them and to identify and avoid any potential dangers independently.

• Electricians have the professional training, skills and experience, and knowledge

of the relevant standards and provisions to work on electrical systems and to

detect and avoid any potential dangers independently.

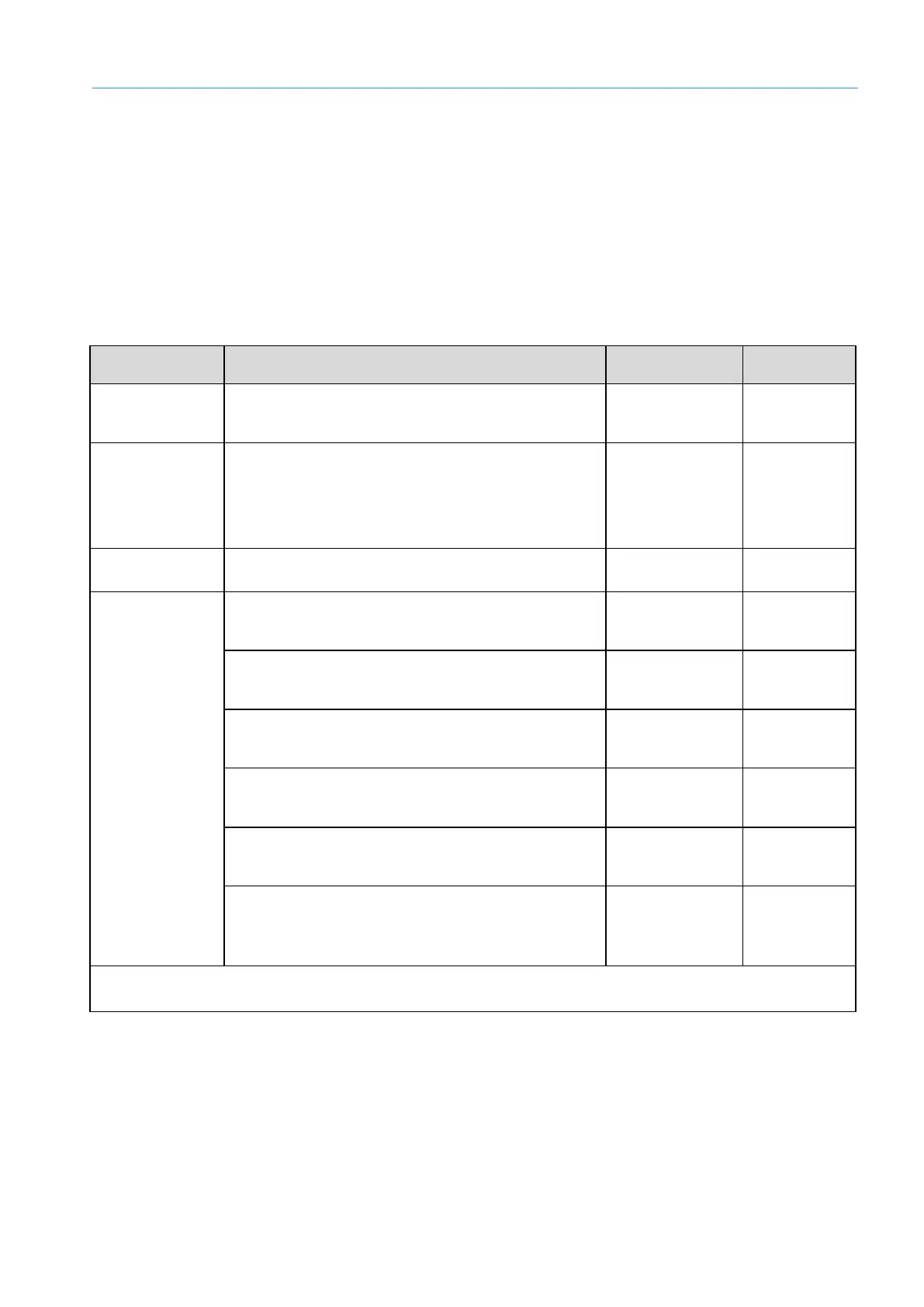

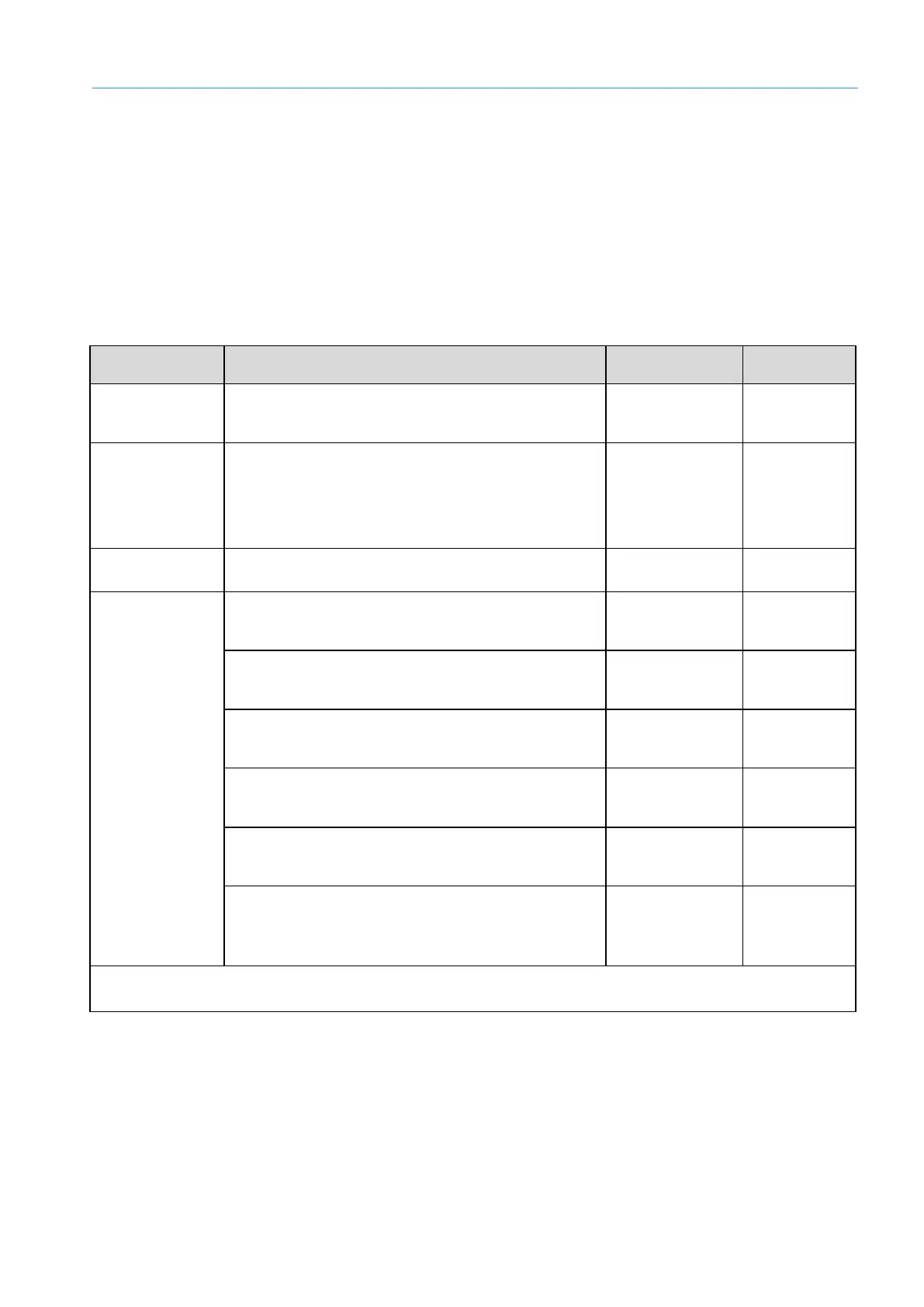

Device Maintenance task Interval* Performed by

LMS500 Clean the front screen 1x/month

Trained

personnel

Photoelectric

retro-reflective

sensor

Cleaning the light emission and reflector

Visually inspect the object detection photoelectric

sensor and reflector for rotation that may have

occurred as a result of touching or the like

4x/year

Trained

personnel

Cabinet

Clean the air inlets and outlets

Replace the filter mat in the air inlets and outlets

4x/year

General

Visual inspection for contamination Daily

Trained

personnel

Optical monitoring of conveying equipment for foreign

bodies/damage

Daily

Trained

personnel

Control measurements with test objects to check the

measurement accuracy of the VMS6200

Whenever the

system is started

Trained

personnel

Visual inspection of the electrical cabling and wiring

for damage

1x/year

Trained

personnel

Maintenance of the individual components 2x/year

Service

technicians

Checking the complete system including measurement

system/reading performance/image quality/reading

range

1x/year

Service

technicians

* The intervals depend on the ambient conditions and degree of contamination. In addition, the intervals must be defined

according to how important they are for the customer process.

Tab. 10: Maintenance intervals

Loading...

Loading...