3 SYSTEM DESCRIPTION

TRANSLATION OF THE ORIGINAL OPERATING INSTRUCTIONS| VMS6200

Subject to change without notice

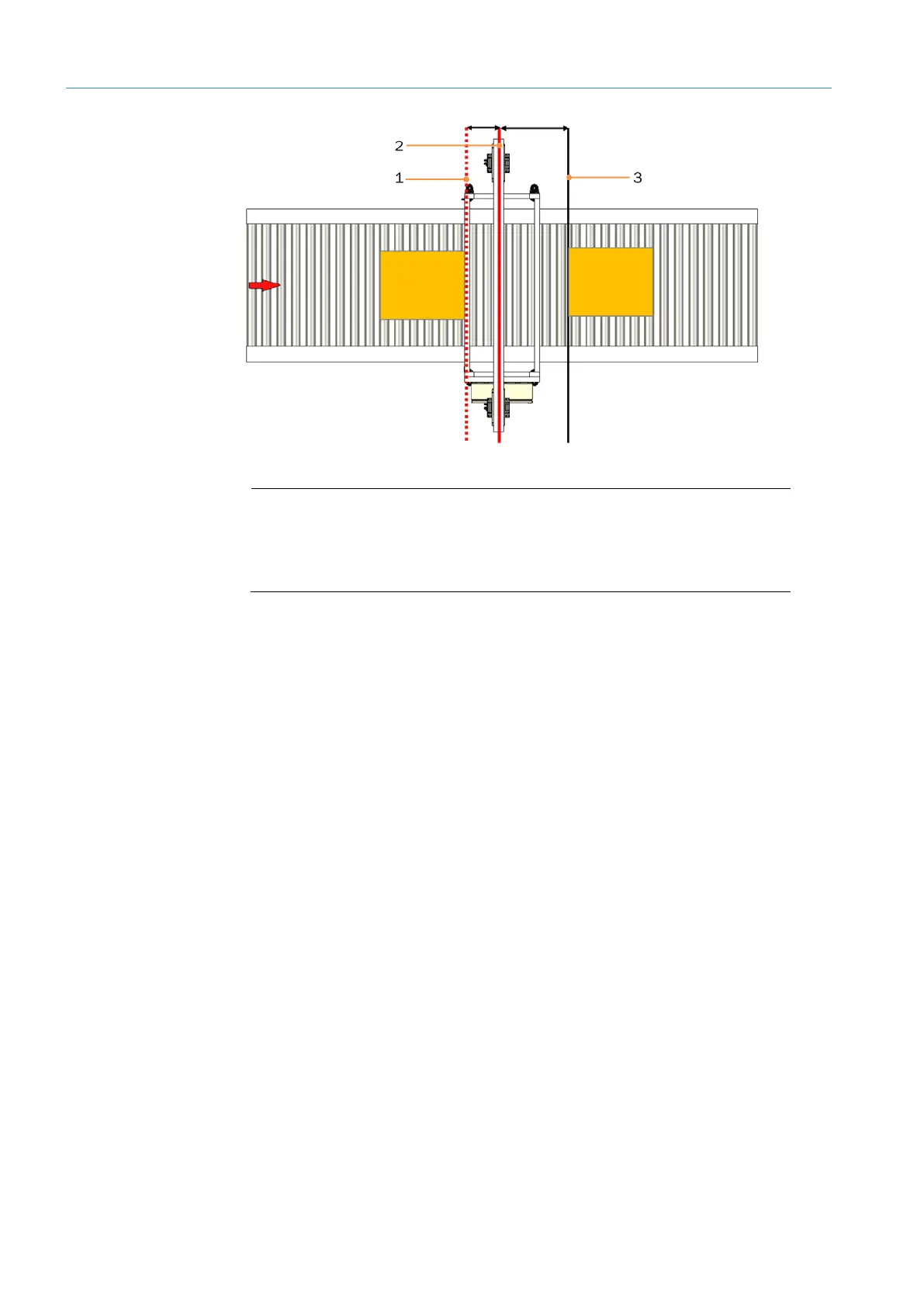

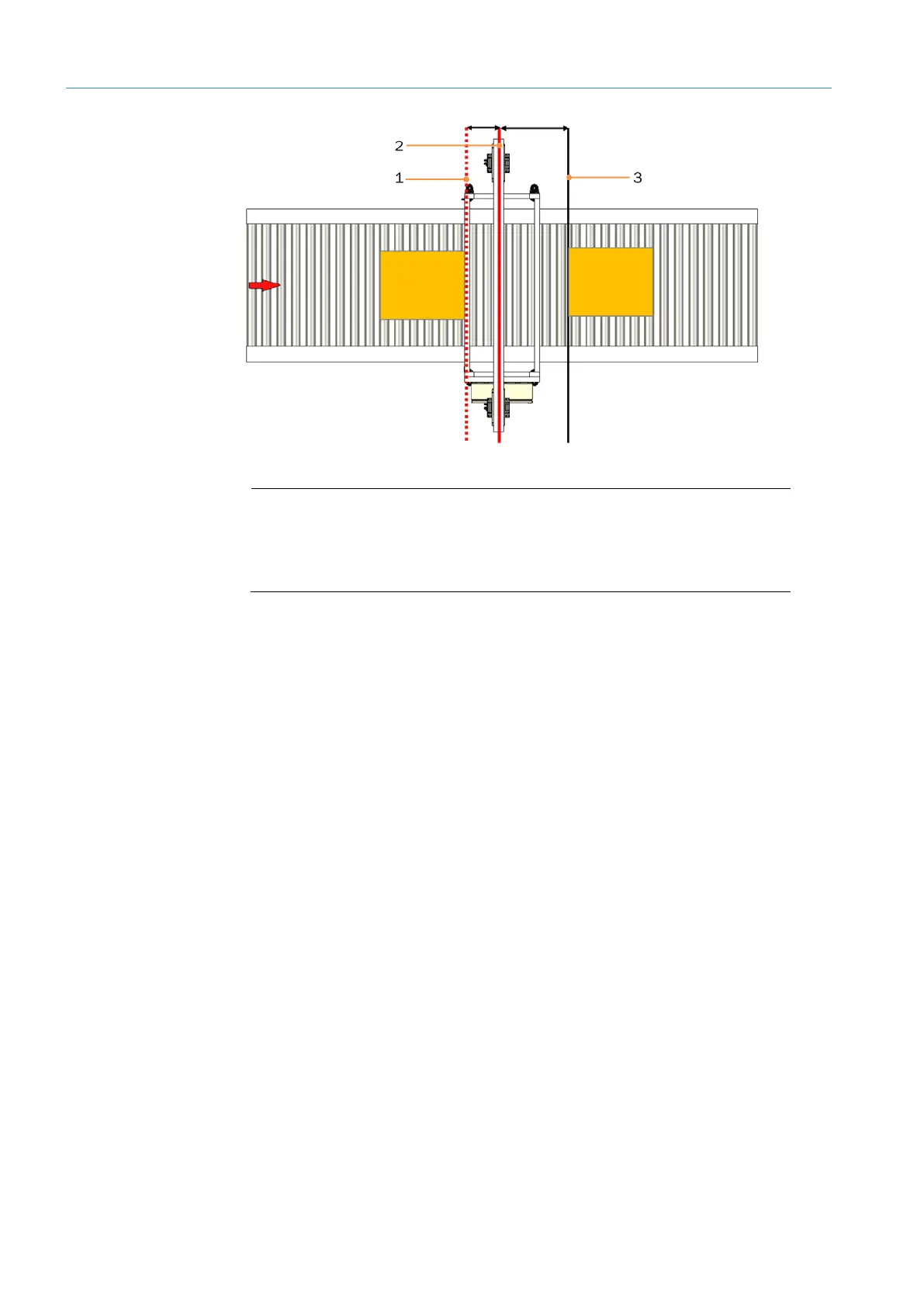

Fig. 15: Trigger and time of data output

Legend

1 Trigger line (e.g., photoelectric retro-reflective sensor)

2 Scan line of the volume measurement devices

3 Earliest data output time

• The minimum distance between the trigger line and the scan line of the two LMS500

sensors is 300 mm.

• The earliest that the calculated dimensions are sent to downstream systems is at a

point 300 mm +200 ms past the scan line.

▸

Make sure that the LMS500 has a clear view of the conveying equipment.

• The LMS500 must be far enough away from bends, induction lines, start/stop areas,

areas with upward and downward slopes, and breaks in the conveying system.

• No side guards are to be mounted in the vicinity of the scan lines.

• The incremental encoder should – if possible – be mounted in the immediate vicinity of

the scan line of the volume measurement devices.

Mounting

the trigger

Optimizing the

scan result

Loading...

Loading...