12.93 6 NC Machine Data (NC MD), NC Setting Data (NC SD)

6.12.1 NC setting data (NC SD)

General setting data

Dry run feedrate

0

Default value Lower input limit Upper input limit Units

00

1072 0000

9999 9999 (as from

SW 5)

1 000 units/min

Active on

–

If ”Dry run feedrate” is selected on the control, the tool path feedrate selected is the dry run

feedrate (mm/min (G94)) and not the programmed feedrate.

Dyn. smoothing time thread cutting

1

Default value Lower input limit Upper input limit Units

0052

n

-1 ×IPO cycle

Active on

–

Programming smoothing exponent via G92 T..

This function is used to protect the drive when cutting threads and to obtain a better speed

stability.

The feed ramp-up time until synchronization with the working spindle already running is

reached can be programmed using the command G92 T.. . The feed ramp-up time should be

matched to the running path available:

• short run-in path, short ramp-up time, low T value

• long run-in path, long ramp-up time, high T value

The programmed ramp-up time also acts as the smoothing time, i.e. the actual spindle speed

is averaged via this value an even feedrate is thus obtained.

The smoothing and feed ramp-up time depends on

• the programmed value T..

• the interpolation cycle which is set in NC MD 155; this machine data should only be

changed by a properly trained specialist.

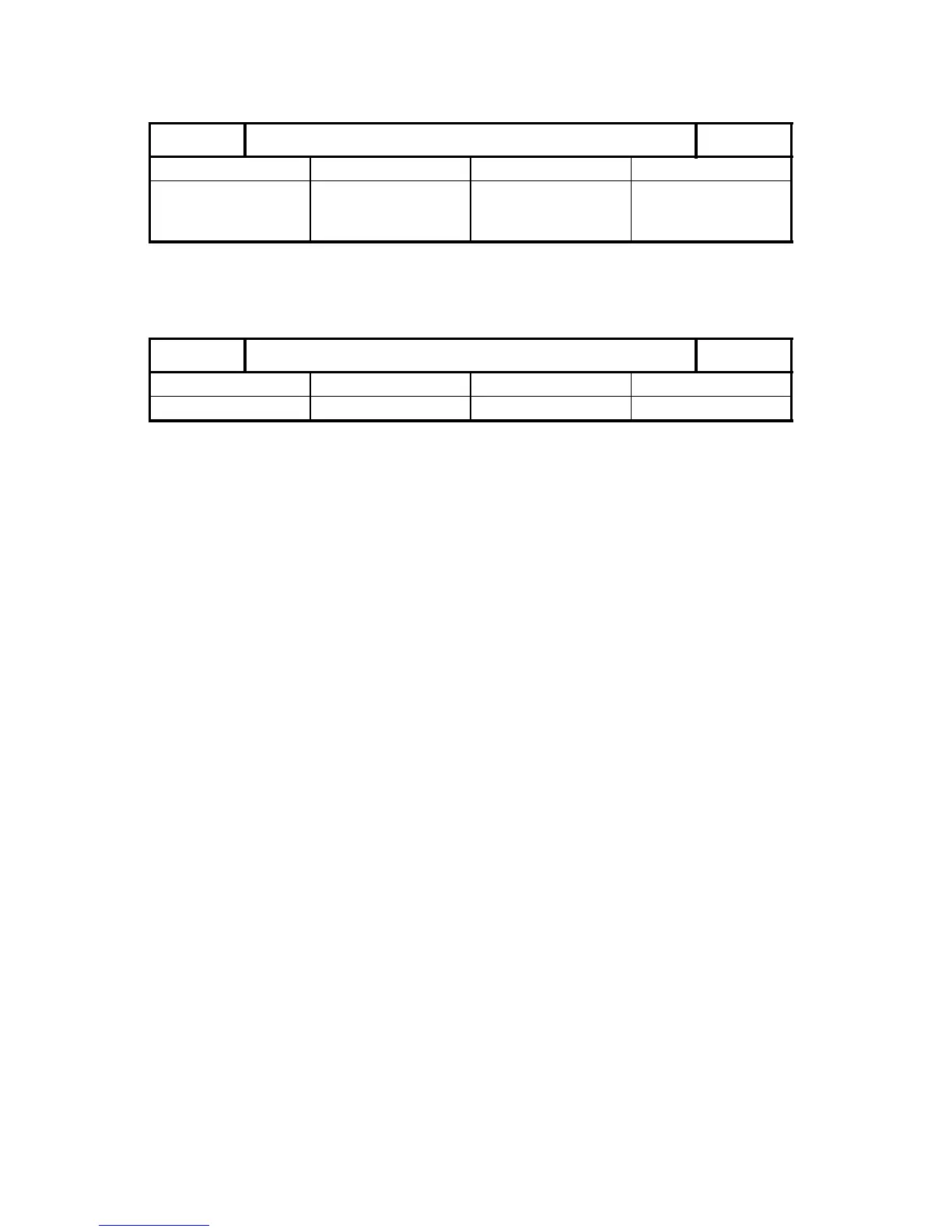

The value T.. must be an integer. Possible values are 0...5. The following table shows which T

value must be programmed for a set interpolation cycle in order to obtain the required feed

ramp-up time:

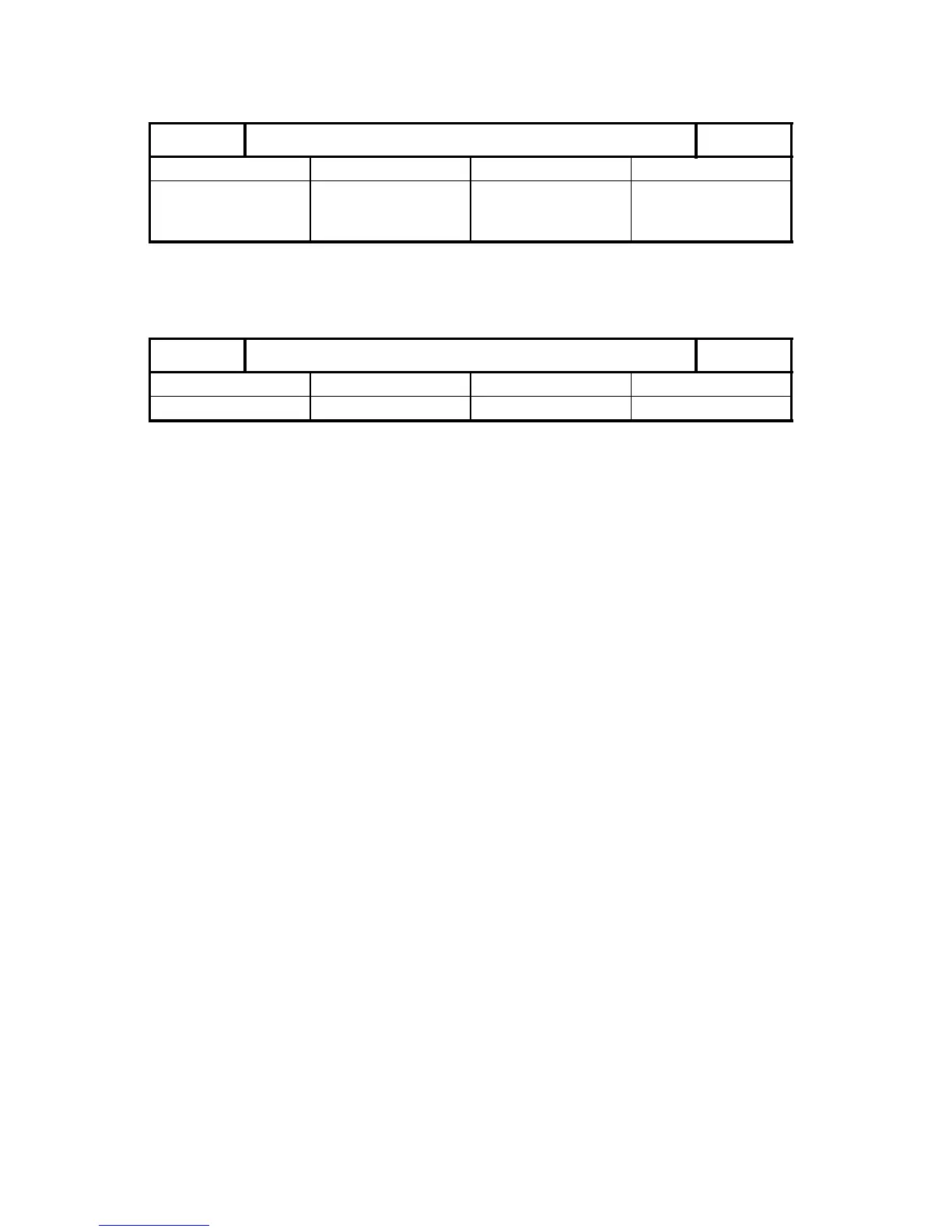

Thread cutting with constant lead (G33)

Thread cutting with linear increasing lead (G34)

Thread cutting with linear decreasing lead (G35)

Program syntax:

N.. G33 <Coordinates of target point> <thread lead>

N.. G34 <Coordinates of target point> <initial lead> <lead change>

N.. G35 <Coordinates of target point> <initial lead> <lead change>

The action of G functions G33, G34, G35 are modal.

The programmed feedrate F has no meaning but remains modal, i.e. the feedrate is derived

internally from the actual speed value of the leading spindle.

©

Siemens AG 1992 All Rights Reserved 6FC5197- AA50

6–221

SINUMERIK 840C (IA)

Loading...

Loading...