09.95

Siemens AG 2001 All Rights Reserved 6FC5197–jAA50

9–58

SINUMERIK 840C (IA)

9.5.4.2 Further optimization and intervention options

Checking methods

1st method: Circularity test

2nd method: Display of characteristic – in this display, the compensation amplitude is output

as a % of the maximum speed as a function of the set memory partitioning.

3rd method: Record the learning process for a difficult acceleration (derived from the

SERVICE quadrant error compensation display) with SERVO trace. The following

SERVO trace parameterization is recommended:

Measuring times, trigger conditions:

Trace 2, 3, 4 with start trigger Trace 1, measuring time 200 ms, triggering

time–50 ms

Trace 1: Edge signal threshold for positive passage through zero, edge signal

threshold for negative passage through zero at threshold = 0.

Trace signals:

Trace 1: Partial setpoint FIPO output (for triggering only)

Trace 2: Following error

Trace 3: Learning criterion QEC

Trace 4: Quadrant error

Examination of Trace 2 and 3:

S If the bump can be seen in following error and not in learning criterion QEC,

the measuring time in the area examined must be increased.

S If the bump can be clearly seen in learning criterion QEC and a later fault is

also included, the measuring time must be reduced.

S If vibrations are contained in the following error at the time of the passage

through zero, they must be eliminated by trying other control settings. A very

high position setpoint smoothing can only be considered a solution during the

automatic learning stage. Conditions can also be improved by reducing the

measuring time.

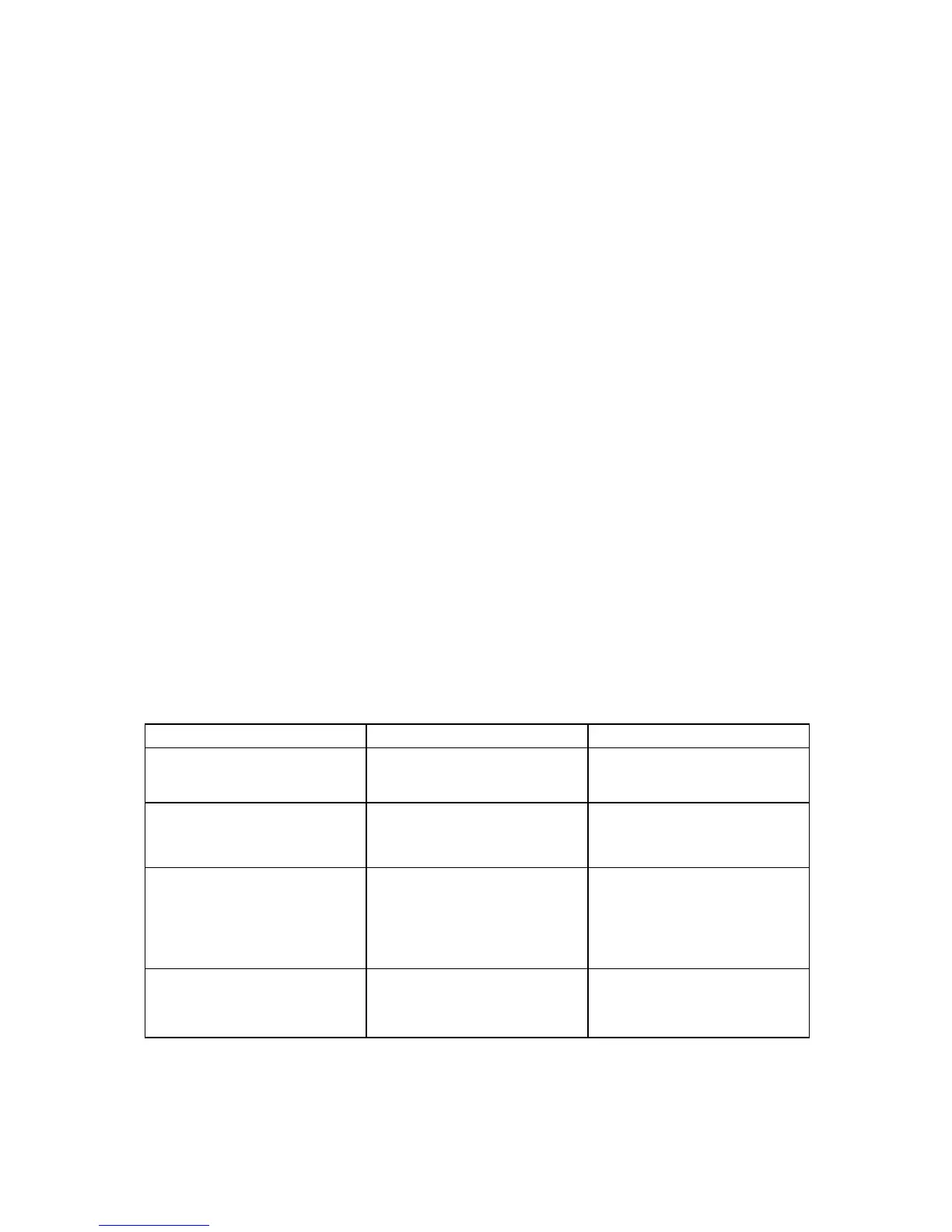

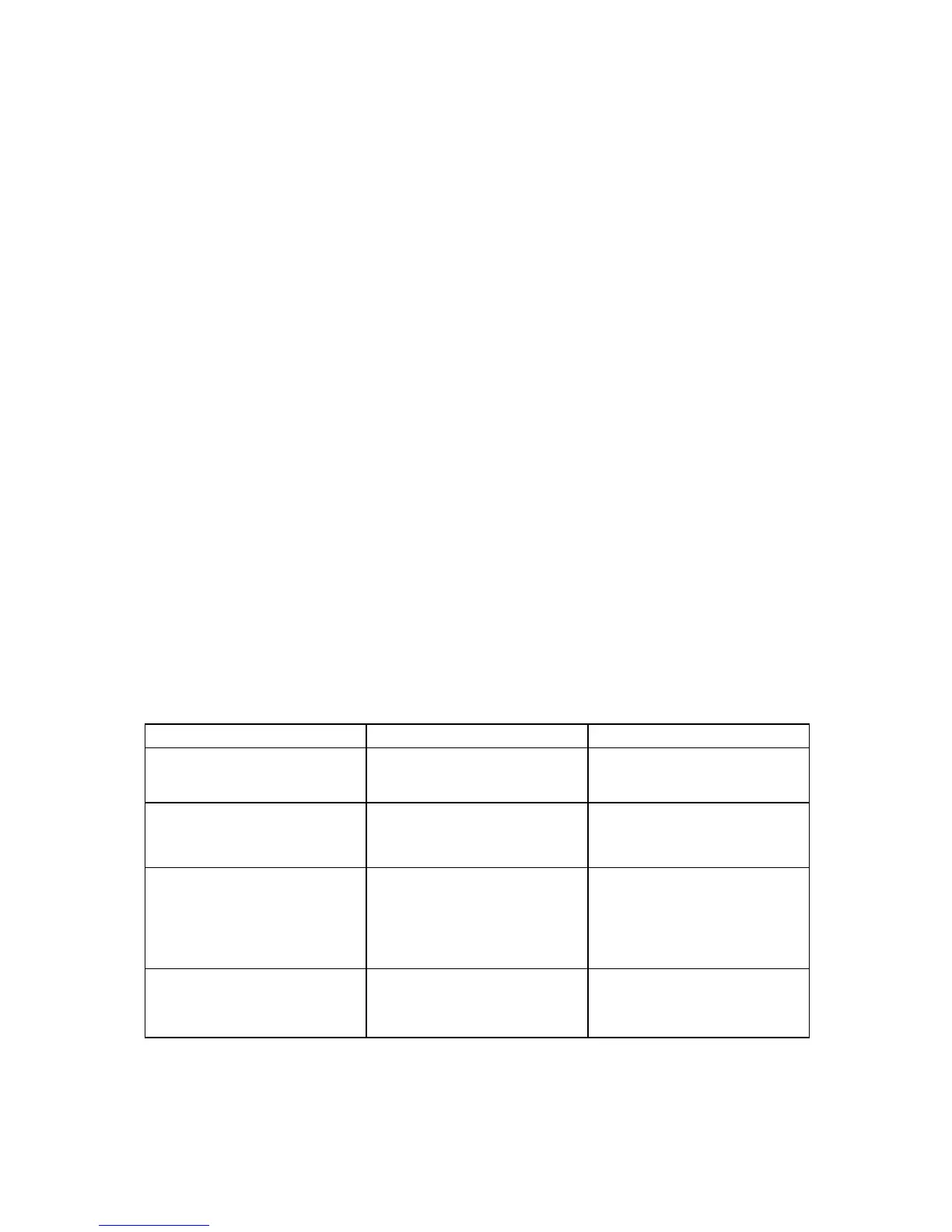

Table: Possible errors and how they can be eliminated

Error:

Recognized by: Remedial action:

Compensation not adequate Circularity test Increase the learning rate or

increase number of learning

passes

Overcompensation in the lower

and middle range

S Circularity test

S Display of the characteristic:

Overshooting in this range

Increase measuring time in this

range (MD 1372*, MD 1376*)

Over compensation in the upper

range

S Circularity test

S Display of the characteristic:

Overshooting in this range

S Check with SERVO Trace

Check the following error and

learning criteria QEC with

SERVO Trace or DAC output and

adapt the measuring time in this

range on the basis of that

information (MD 1380*)

Large fluctuations in

compensation: sometimes

overcompensation, sometimes

undercompensation

S Circularity test

S Display of the characteristic:

Large fluctuations

Decrease learning rate, restart

learning process (with fewer

learning passes)

9 Drive Servo Start-Up Application (as from SW 3)

9.5.4 Neural quadrant error compensation (QEC – SW 4)

Loading...

Loading...