12.93 12 Functional Descriptions

12.18.13 Start-up

12.18.13.2 Full start-up procedure

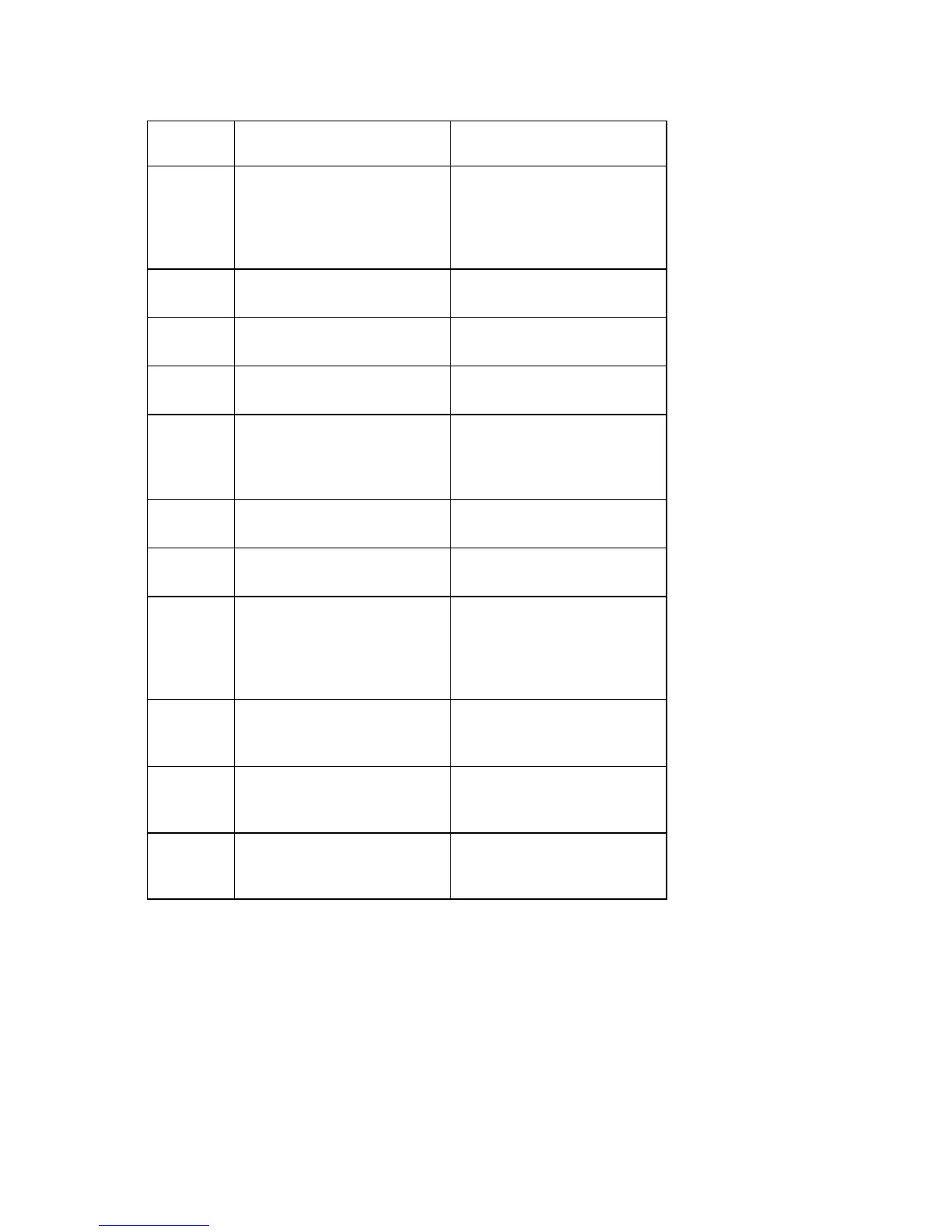

Step Action Important information

1 Define position control

sampling time

Following drive and

associated leading drives

must generally have the

same position control

sampling times.

2 Set drift compensation

(applies only to analog drives)

Deactivate feedforward

control and link beforehand

3 Carry out general optimization

of axes and spindles

Servo gain factor must be

correct (following error check)

4 Set feedforward control Check effect of feedforward

control on the following error

5 Match dynamic response of

individual drives

With setpoint links, the

leading and following drives

must have the same dynamic

response (rise time).

6 Set the required machine

data

Initial configuration must be

enabled

7 Optimize the compensatory

controller

Switch on link and FD overlay

8 Calculate the time constants

of the parallel model

Check synchronism error in

service display; deactivate

compensatory controller;

feedforward control must be

fully set

9 Define the GI monitoring

tolerances according to

manufacturer's data

Check in service display (indi-

vidual spindle/individual axis)

Synchronism error

10 Check the GI programming

functions

Configuration;

Activate/deactivate link;

on-the-fly synchronization

11 Set the interlocks Interlocks, e.g. set

reconfiguration etc. (NC MD

bits)

© Siemens AG 1992 All Rights Reserved 6FC5197- AA50 12–155

SINUMERIK 840C (IA)

Loading...

Loading...