∅° = sin

-1

(VOS / V

phase

) Where: VOS = Velocity of sound in liquid

V

phase

= Phase velocity of sensor

T

L

= 2 * ID / (VOS * cos

∅) ID = Pipe inside diameter

T

L

= Transit time in liquid

V

F

= V

phase

* DT / (2 * TL) DT = Measured Transit-Time difference

V

F

= Flow Velocity

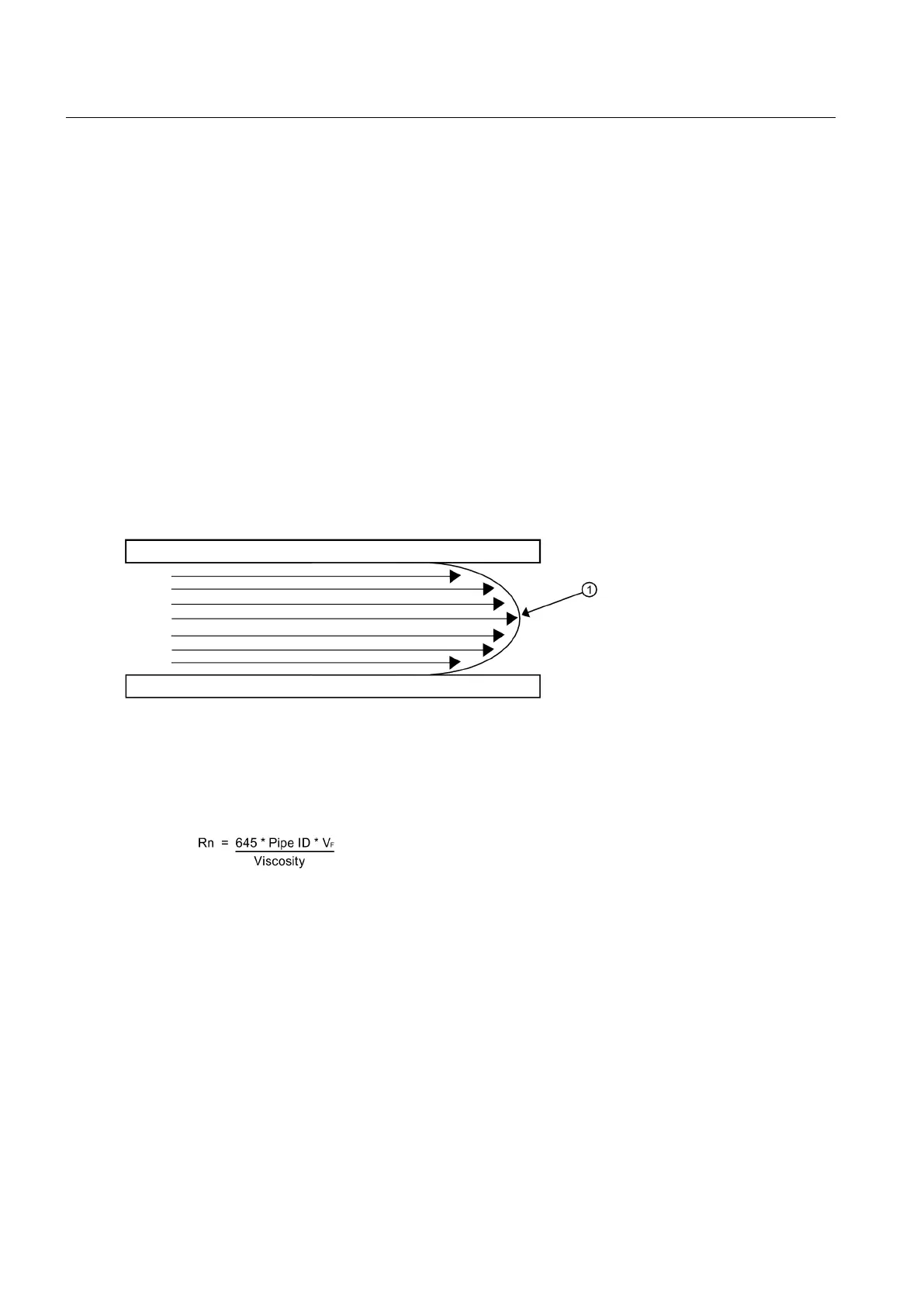

Flow Profile Compensation

Another important consideration is that the ultrasonic flowmeter has to compensate for the

flow profile to maintain calibration accuracy. Shown below is a graphic of a "fully-developed"

flow profile. Note that the fluid velocity increases toward the center (axis) of the flow stream.

① Fluid velocity near the axis of the flow stream tends to be greater.

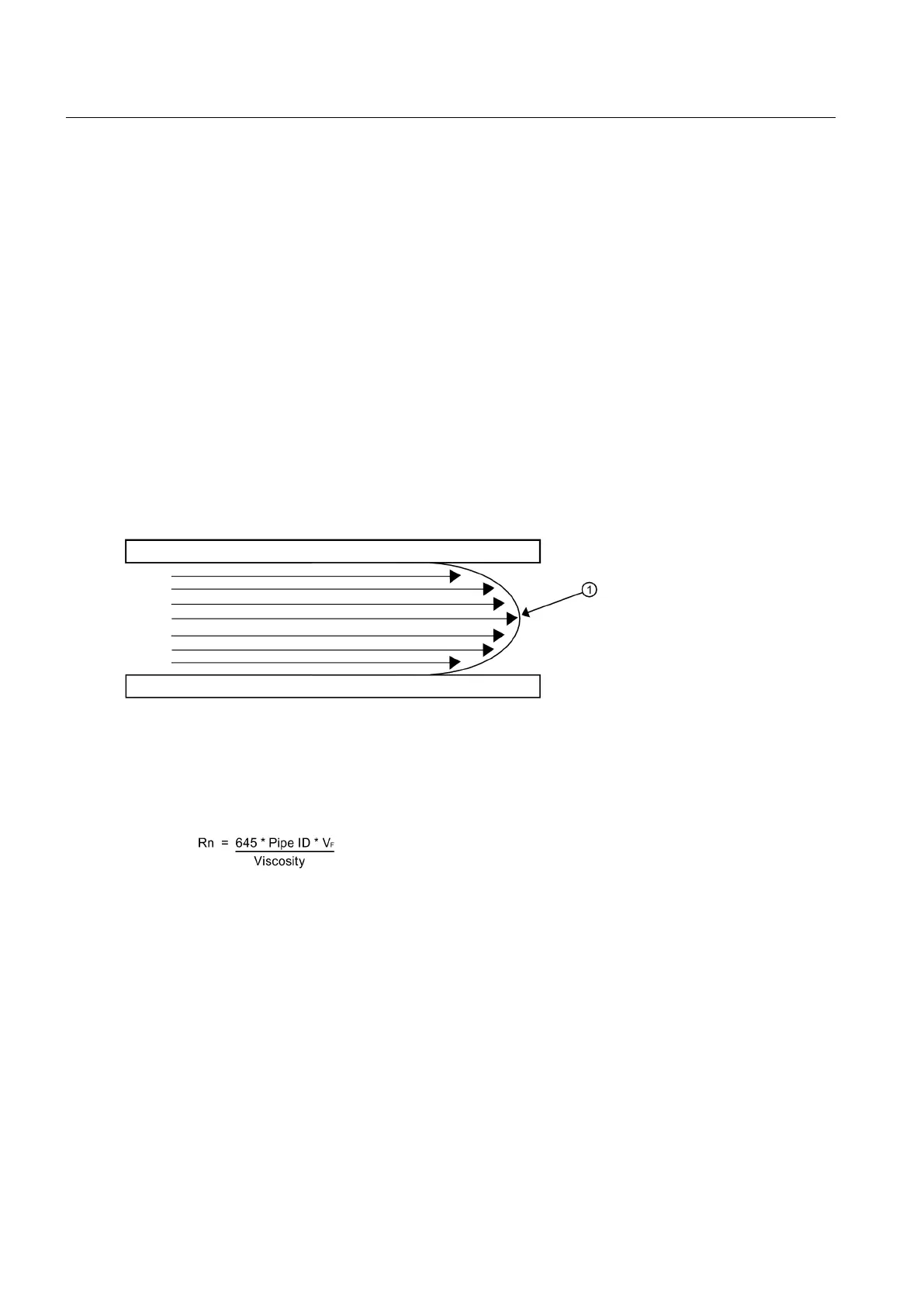

The Reynolds number is then computed as follows:

where viscosity = cS = cP/density

cS = kinematic viscosity

cP = absolute viscosity

The flowmeter then uses this computation of Reynolds number to compensate the raw flow

velocity for conditions of laminar or turbulent flow profile as defined by an internal Reynolds

compensation table. The flowmeter then

converts the compensated flow velocity to volumetric

flow rate.

Rate = V

F

* Comp(Rn) * Pipe area

Description

3.3 Theory of Operation

FUP1010 IP67 Portable Flowmeter

14

Operating Instructions, 02/2010, A5E02951522A Revision 01

Loading...

Loading...