● Chemical Processing

● Food and Pharmaceutical

● Aircraft Avionics and Ground Support

● Water and Wastewater

● Aerospace

● Automobile Manufacturing

● Hydrocarbon Industries

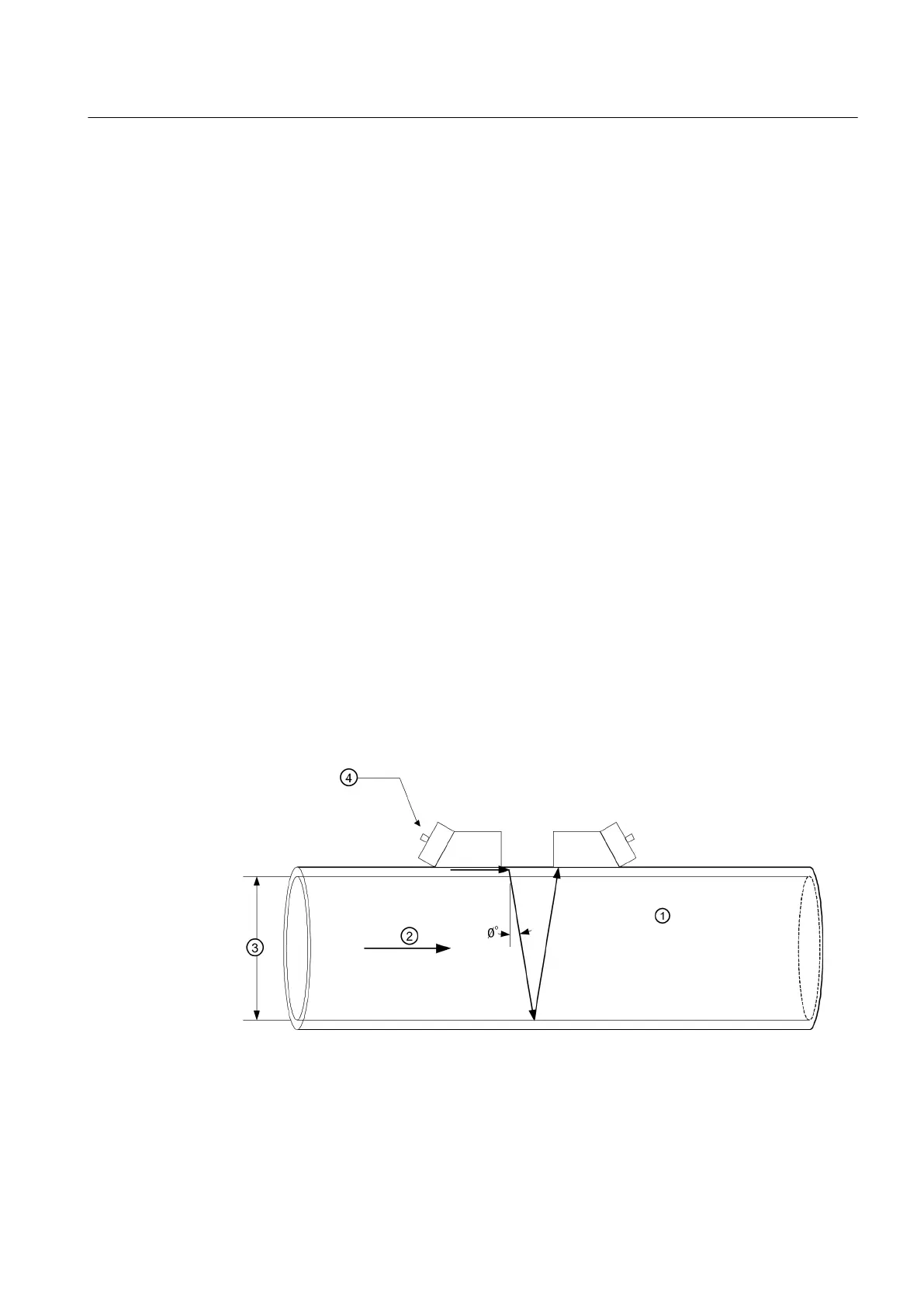

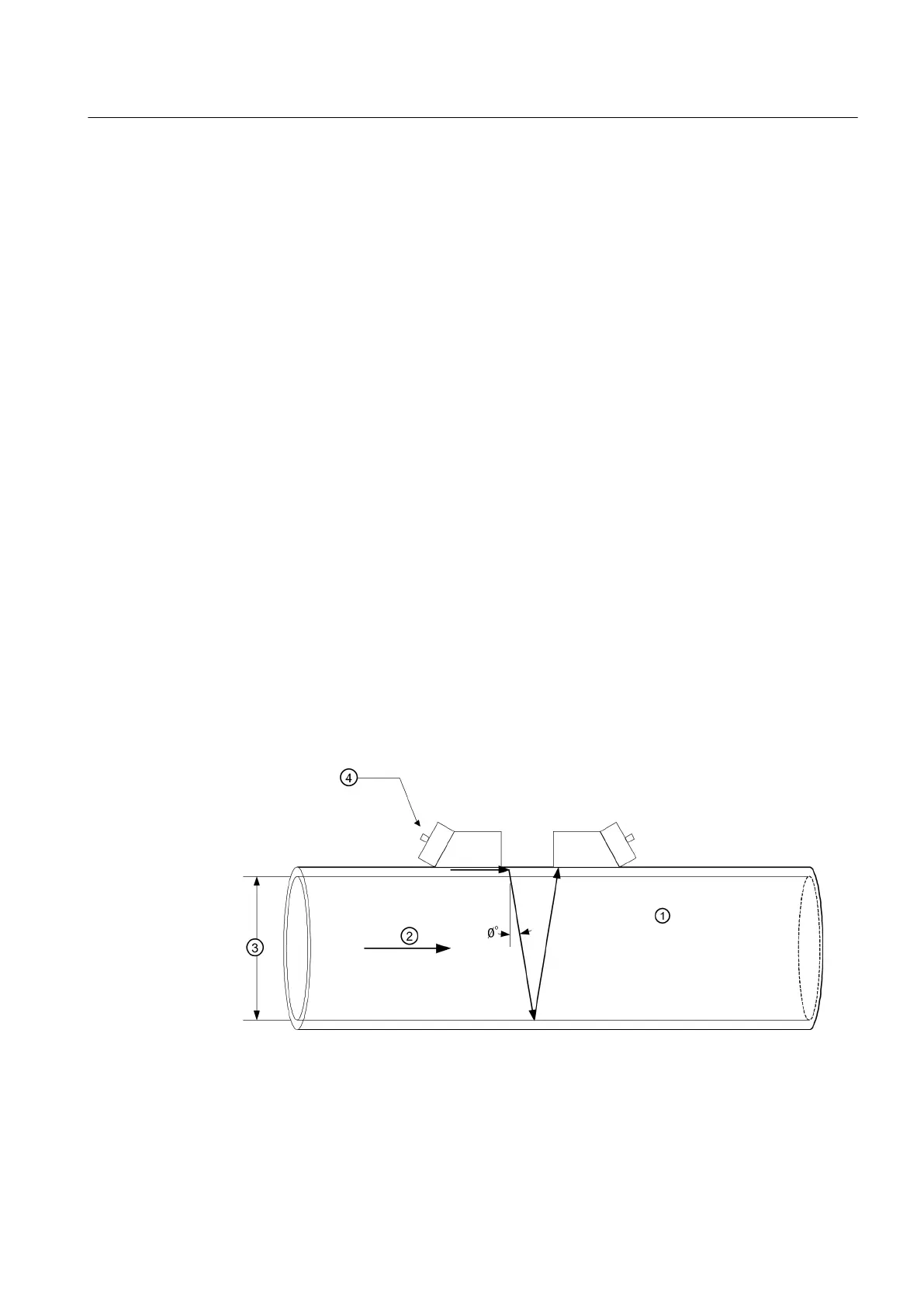

3.3 Theory of Operation

The liquid flowmeter relies on the MultiPulse transit. Two Wide-Beam ultrasonic sensors per

measuring path, alternating as transmitter and receiver, are used to interrogate the liquid

flowing within the metering section. The resulting time of arrival for each direction of transmit

(upstream and downstream) is then measured using a highly accurate and stable digital signal

processing method.

Using this detection scheme, the flowmeter is capable of resolving the relative transit-time

difference (dT) to within ±100 psec. Considering typical liquid flow transit-time differences

ranging from 1x10

4

to 1x10

6

psec, the flowmeter is capable of providing an exceptional turn-

down ratio. The flowmeter also incorporates a correlation technique which enables the system

to detect very high flow velocities with the same high degree of resolution. The ultrasonic

sensors are designed with sufficient beam divergence characteristics to insure that the receive

sensor will always have sufficient signal to maintain operation under conditions of high beam

blowing associated with high flow velocities.

With accurate signal arrival time available, the flowmeter can compute the raw flow velocity

from the measured upstream and downstream transit times.

① Velocity of Sound

② Flow Vector

③ Pipe ID

Description

3.3 Theory of Operation

FUP1010 IP67 Portable Flowmeter

Operating Instructions, 02/2010, A5E02951522A Revision 01

13

④ Wide Beam Sensors

Loading...

Loading...